Effective Drilling Mud Management Techniques for Oil and Gas Industry

By:Admin

One of the key challenges in the oil and gas industry is the management of drilling mud. Drilling mud, also known as drilling fluid, is a critical component in the drilling process. It is used to lubricate the drill bit, carry cuttings to the surface, control wellbore pressure, and provide stability to the wellbore. However, the proper management of drilling mud is essential to ensure the success of drilling operations and minimize environmental impact.

To address this challenge, {company} has developed a state-of-the-art Drilling Mud Management system that is designed to optimize the performance of drilling mud while minimizing waste and environmental impact. The system incorporates advanced technologies and best practices to effectively treat, recycle, and dispose of drilling mud, ensuring compliance with environmental regulations and industry standards.

One of the key features of {company}'s Drilling Mud Management system is its ability to efficiently separate solids from the drilling mud, allowing for the reuse of the fluid and the disposal of the solids in an environmentally responsible manner. This not only reduces waste and lowers operational costs, but also minimizes the environmental footprint of drilling operations.

In addition, the system is equipped with advanced filtration and purification technologies to ensure that the recycled drilling mud meets the required specifications for reuse in drilling operations. This not only improves the efficiency of the drilling process but also reduces the need for fresh water, which is a precious resource in many drilling locations.

Furthermore, {company}'s Drilling Mud Management system is designed to adapt to the specific requirements of each drilling operation, providing a customized solution that is tailored to the unique challenges and objectives of each project. This ensures that the system can effectively address the complexities of different drilling environments and well conditions, while maximizing the performance and efficiency of drilling mud.

Moreover, {company} also offers comprehensive support and services to accompany its Drilling Mud Management system, including engineering expertise, technical assistance, and training programs. This ensures that customers have access to the necessary knowledge and resources to fully leverage the capabilities of the system and achieve optimal results.

By implementing {company}'s Drilling Mud Management system, oil and gas companies can benefit from improved operational efficiency, reduced environmental impact, and enhanced regulatory compliance. This not only contributes to the sustainability and responsible stewardship of natural resources but also enhances the overall profitability and competitiveness of drilling operations.

It is clear that {company} remains committed to delivering innovative solutions that address the evolving needs of the energy industry. Through its Drilling Mud Management system, the company is empowering oil and gas companies to achieve greater efficiency, minimize waste, and uphold the highest standards of environmental stewardship. With its advanced technologies, industry expertise, and global presence, {company} is poised to continue leading the way in shaping the future of the energy sector.

Company News & Blog

Essential Guide to Drilling Solids Control Equipment - Venturi Hopper

The oilfield industry is an essential sector in any economy, and ensuring that it remains productive and sustainable is critical to maintaining its ongoing success. One of the fundamental aspects of oilfield production is solid control, which is the process of managing the solids that are generated during drilling operations. These solids include drill cuttings, rock fragments, and debris, and it is imperative to remove them efficiently and effectively to preserve the drilling equipment and ensure that the drilling operations can continue smoothly.To achieve this, the oilfield industry relies on various equipment, one of which is the Venturi hopper, a part of the mud mixing pump. This can be made of either carbon steel or stainless steel and is designed to work in combination with the mud mixing pump. The Venturi hopper is an essential component of the oilfield solids control system and plays a critical role in ensuring the proper management of solids during drilling operations.The role of the Venturi hopper in the oilfield solids control system is to mix and agitate the drilling mud, thereby improving the overall efficiency of the mud mixing pump. The hopper works by drawing the drilling mud through a narrow throat, which produces a vacuum effect that causes an increase in the fluid velocity. This increase in velocity leads to the injection of air or dry powder into the mud stream, which results in a more effective mixing process.One of the key benefits of the Venturi hopper is its ability to handle a wide range of drilling fluids, including both low and high-density muds. This makes it an ideal solution for use in a variety of drilling applications, including oil and gas drilling operations, mining operations, and geothermal drilling operations.There are various types of Venturi hoppers available on the market, and each is designed to meet the specific needs of different drilling operations. For example, some hoppers are designed for use in high-pressure applications, while others are suitable for use in low-pressure applications. There are also hoppers available that are specifically designed to handle abrasive drilling fluids, which can cause significant wear and tear on other types of solids control equipment.In addition to its critical role in the solids control system, the Venturi hopper is also an essential component in the overall efficiency and sustainability of oilfield production. By ensuring that solids are effectively and efficiently removed from the drilling fluids, the hopper helps to preserve the drilling equipment, reducing the need for frequent maintenance and repair. This, in turn, helps to reduce the cost of operations and improve the overall profitability of the oilfield industry.Overall, the Venturi hopper is an essential component of the oilfield solids control system, providing a critical function in the proper management of solids during drilling operations. By working in combination with the mud mixing pump, the hopper improves the overall efficiency of the drilling process, reduces the need for costly maintenance and repair, and helps to ensure the ongoing sustainability and success of the oilfield industry. With its versatility and effectiveness, the Venturi hopper is a must-have for any drilling operation, playing a crucial role in the smooth and sustainable operation of the oilfield industry.

High-Quality Centrifuges for Laboratory and Medical Use, Hand-Operated Options Available

China-based company [Company Name] has recently introduced a new line of centrifuge products, including a high-speed centrifuge and a hand-operated centrifuge, aimed at serving the needs of various industries, including medical, research, and industrial settings.The high-speed centrifuge is designed to provide efficient and reliable separation of substances, such as blood, urine, and other biological samples. With its advanced technology, the high-speed centrifuge is able to rapidly spin samples at high speeds, resulting in quick and precise separation of components. This is particularly beneficial in medical laboratories and research facilities where time is crucial and accurate results are paramount.On the other hand, the hand-operated centrifuge is a portable and versatile solution for smaller-scale separation tasks. This compact device is designed for situations where access to a power source is limited or when a smaller volume of samples needs to be processed. It can be used in various settings, such as field research, remote clinics, and educational laboratories.[Company Name] has a long history of developing and manufacturing high-quality centrifuge equipment for various applications. With a focus on technological innovation and product excellence, the company has established itself as a trusted supplier of centrifuge solutions in the global market.The company's commitment to quality and performance is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. Each centrifuge product undergoes comprehensive testing and inspection to ensure it meets the highest standards of reliability and efficiency.In addition to its technical expertise, [Company Name] also prides itself on providing exceptional customer service and support. The company's dedicated team of professionals is well-equipped to offer personalized advice and assistance to customers, helping them select the most suitable centrifuge solution for their specific needs.The introduction of the new high-speed and hand-operated centrifuge products further demonstrates [Company Name]'s dedication to meeting the evolving needs of its customers. By continuously expanding its product range and incorporating the latest technological advancements, the company aims to remain at the forefront of the centrifuge industry.The global demand for centrifuge equipment continues to grow, driven by increasing applications in the fields of healthcare, biotechnology, and research. [Company Name] is well-positioned to capitalize on this trend through its innovative product offerings and commitment to customer satisfaction.While the high-speed centrifuge is designed for high-throughput laboratories and facilities with demanding separation requirements, the hand-operated centrifuge is expected to appeal to customers seeking a portable and cost-effective solution for smaller-scale applications. Both products are expected to contribute to [Company Name]'s continued success in the centrifuge market.As [Company Name] looks to the future, it remains steadfast in its commitment to innovation, quality, and customer satisfaction. With its new line of centrifuge products, the company is poised to make a significant impact in the global market and solidify its reputation as a leading provider of centrifuge solutions.

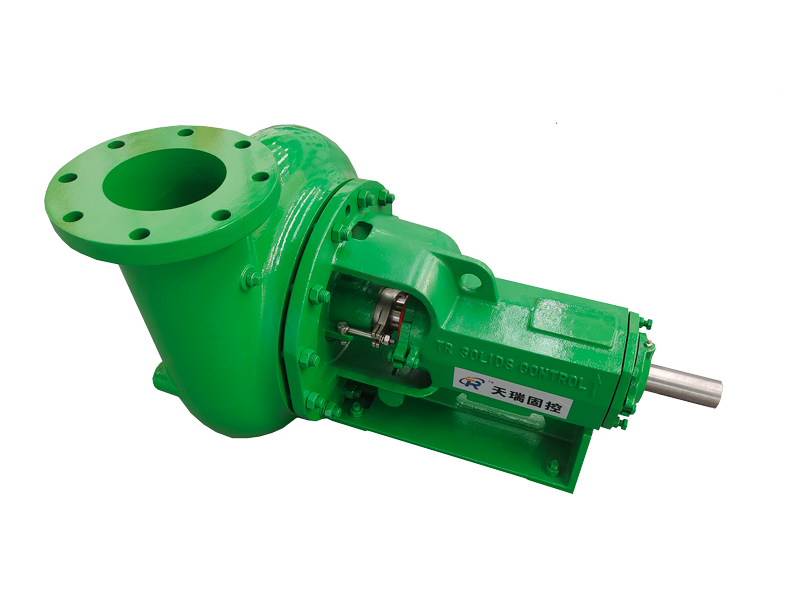

China Submersible Centrifugal and Mud Pump: Latest Developments

China Submersible Centrifugal Pump and Submersible Mud Pump Spearhead Global Market DominanceChina has once again demonstrated its ability to lead the global pump industry with the development and production of innovative submersible centrifugal and mud pumps. These cutting-edge machines, designed to efficiently transport fluids and solid materials, have cemented China's position as a frontrunner in the international pump market.The submersible centrifugal pump, a remarkable engineering feat manufactured in China, has garnered significant attention worldwide for its outstanding performance and reliability. Combining advanced technology and state-of-the-art design, this pump operates underwater, ensuring efficient fluid transportation in a variety of demanding applications.Built for versatility, the submersible centrifugal pump is capable of handling various types of liquids, including water, oil, and chemicals. With its exceptional resistance to corrosion and wear, the pump can be used in industries such as oil and gas, mining, agriculture, and sewage treatment. Its ability to function effectively even in harsh and challenging environments has made it a go-to choice for projects worldwide.Designed with simplicity and efficiency in mind, the submersible centrifugal pump requires minimal maintenance, reducing downtime and ensuring continuous operations. Equipped with powerful motors, this pump can deliver high flow rates and achieve impressive lift heights, making it an indispensable tool for projects requiring fluid transport over long distances.Another breakthrough in China's pump industry is the submersible mud pump, which has revolutionized the handling of solid materials. This innovative pump is specifically designed for projects involving the transfer of sludge, slurry, and other viscous substances. With its outstanding ability to handle heavy solids, it has become an indispensable tool in diverse sectors, including construction, mining, and waste management.The submersible mud pump's impressive capacity to transport large volumes of solid materials has greatly contributed to the efficiency and productivity of various industries worldwide. Its robust construction ensures durability and longevity even when subjected to rigorous operating conditions. By effectively eliminating the need for manual labor-intensive methods, such as shoveling and dredging, the submersible mud pump has significantly enhanced operational efficiency and reduced costs.China's relentless pursuit of innovation and technological advancement has bolstered the country's reputation as a global leader in the pump industry. With their commitment to research and development, Chinese manufacturers have continued to introduce groundbreaking solutions that cater to the evolving needs of various sectors across the world.The superior quality and reliability of Chinese submersible centrifugal and mud pumps have propelled their global market dominance. In recent years, China has emerged as the largest exporter of pumps, exporting to more than 190 countries and regions, attesting to the widespread recognition and acceptance of Chinese pump products. This prominence is primarily due to the country's ability to produce pumps of exceptional quality at competitive prices.Furthermore, China's extensive investment in infrastructure development and its focus on sustainable solutions have created vast opportunities for the submersible centrifugal and mud pump industry. Growing demand from sectors such as construction, agriculture, and energy has buoyed the industry's growth and positioned Chinese manufacturers at the pinnacle of success.Looking ahead, China's pump industry is poised to expand further, driven by continued advancements in technology and the growing global demand for efficient fluid handling solutions. With its unrivaled manufacturing capabilities, commitment to innovation, and ability to customize products to suit specific requirements, China is set to solidify its position as the undisputed leader in the submersible centrifugal and mud pump market.As Chinese pump manufacturers continue to forge ahead with their pursuit of excellence, the global industry can expect to witness even greater advancements and remarkable achievements in the years to come.

High Quality 240m3/h Mud Cleaning Equipment with 4" Desilter Cones and Bottom Shale Shaker - Efficient Mud Cleaning Systems

Discover the Latest Advancements in High-Performance Mixing: Unveiling Revolutionary Shear Mixers

Title: Advanced Mixing Technology Streamlines Industrial ProcessesSubtitle: Shear Mixer Revolutionizes Mixing EfficiencyDate: [Insert date][City/Region], [Country] - Combining cutting-edge technology and years of research, an innovative shear mixer has unveiled its game-changing solution for industrial mixing. Developed by [Company Name], a leading provider of advanced equipment for various industries, this revolutionary mixer promises to enhance productivity, consistency, and efficiency in the manufacturing processes.[Company Name] has been at the forefront of developing specialized machinery for industrial applications. With a commitment to continuous improvement and technological advancement, they have introduced the latest addition to their impressive product line - the shear mixer.The shear mixer presents a paradigm shift in the field of mixing technology. With its precision engineering and state-of-the-art features, it has the potential to redefine industries that heavily rely on mixing, such as pharmaceuticals, food processing, chemicals, and cosmetics.One of the standout features of the shear mixer is its ability to provide unparalleled blending efficiency. Equipped with an advanced mixing chamber design, the shear mixer ensures optimal distribution of materials, achieving a homogenous blend in significantly reduced time. This attribute translates into increased productivity and cost savings for manufacturers by minimizing downtime and enhancing overall output.Moreover, the shear mixer offers utmost versatility, capable of handling a wide range of viscosities and materials. Its robust construction and build quality enable it to withstand demanding industrial environments, making it a reliable choice for various applications. From powders to liquids and everything in between, the shear mixer delivers consistent, outstanding results.Efficiency and consistency have always played a crucial role in manufacturing processes. Recognizing this need, [Company Name] has equipped the shear mixer with innovative controls and monitoring capabilities, ensuring precise and repeatable results. Operators can easily control and adjust parameters such as speed, temperature, and mixing time, ensuring a high level of control and customization to meet individual requirements.In addition to its superior functionality, the shear mixer boasts ease of maintenance. Designed with accessibility in mind, it features quick-change components and a user-friendly interface, allowing for intuitive maintenance and reduced downtime. These attributes make the shear mixer an invaluable tool for plant operators, boosting operational efficiency and minimizing costly equipment downtimes.To ensure seamless integration into existing production lines, [Company Name] offers a comprehensive range of customization options. By working closely with clients, they tailor the shear mixer to suit specific needs, considering factors such as material requirements, production volumes, and space constraints. This flexibility ensures that the shear mixer seamlessly integrates within different manufacturing environments, maximizing its performance and enhancing overall efficiency.As industrial processes evolve and demand for streamlined operations intensifies, the shear mixer represents a major breakthrough in mixing technology. With its exceptional efficiency, versatility, and durability, it is set to revolutionize various sectors, enabling manufacturers to meet and exceed production targets while maintaining the highest quality standards.[Company Name] has consistently demonstrated its commitment to innovation and customer satisfaction, and the shear mixer is another testament to their pioneering efforts. By combining cutting-edge technology with their extensive experience, they have developed a mixing solution that is poised to transform the industrial landscape.In conclusion, the shear mixer presented by [Company Name] represents a game-changer for industrial mixing. With its efficient blending capabilities, versatility, and user-friendly maintenance, it enables manufacturers to optimize their processes and elevate production efficiencies. As industries strive for increased productivity and improved quality, this revolutionary mixer is sure to set new standards in the field of mixing technology.

Top Advantages of Investing in High-Quality Shaker Screens for Oil and Gas Industry

Title: Innovative Shaker Screen Technology Revolutionizes the Oil and Gas IndustryIntroduction: In response to the increasing demand for advanced oil drilling equipment, the renowned company, Mongoose Pro, has proudly launched its latest groundbreaking innovation, the next-generation Shaker Screen. Designed to cater to the specific requirements of the oil and gas industry, this cutting-edge technology promises to revolutionize drilling operations by enhancing efficiency, reducing costs, and improving environmental sustainability. With its exceptional performance and outstanding durability, the Mongoose Pro Shaker Screen is set to promote safer and faster drilling processes, paving the way for unprecedented growth in the sector.Paragraph 1: Overview of the Oil and Gas IndustryThe oil and gas industry plays a vital role in powering our modern society, providing energy sources essential in transportation, electricity generation, heating, and various industries. The process of tapping into these valuable resources involves complex drilling operations, requiring state-of-the-art equipment to optimize efficiency and minimize environmental impact.Paragraph 2: The Role of Shaker Screens in Drilling OperationsShaker screens serve as an integral part of the drilling process, facilitating the separation of drilling fluids and solids. These screens ensure that the drilling mud is consistently in an optimal condition for efficient extraction, while simultaneously reducing waste and protecting the drilling equipment from damage. Innovations in shaker screen technology are crucial in enabling drilling companies to achieve higher productivity and cost-effectiveness.Paragraph 3: Introduction to Mongoose Pro Shaker ScreenRecognizing the industry's needs for superior drilling equipment, Mongoose Pro has taken the lead in developing an advanced line of shaker screens, including their flagship product, the Mongoose Pro Shaker Screen. With extensive research and development, Mongoose Pro has successfully designed a highly efficient screen that offers unparalleled performance in a wide range of drilling environments.Paragraph 4: Key Features and Benefits of Mongoose Pro Shaker ScreenThe Mongoose Pro Shaker Screen boasts several noteworthy features that set it apart from conventional options in the market. Firstly, its proprietary composite frame construction provides outstanding strength and durability, allowing it to withstand the most demanding drilling conditions. Secondly, the screen's revolutionary triple-layered mesh design ensures optimum solid separation efficiency, further enhancing the drilling operation's overall effectiveness.Additionally, the Mongoose Pro Shaker Screen incorporates advanced manufacturing techniques that minimize screen blinding, thereby extending its operational lifespan and reducing downtime for maintenance. This not only improves cost-effectiveness for drilling companies but also promotes environmental sustainability by reducing waste generation.Paragraph 5: Seamless Integration and Enhanced EfficiencyOne of the primary advantages of the Mongoose Pro Shaker Screen is its compatibility with various shaker models. Designed to seamlessly integrate with both Mongoose Pro and other industry-standard shakers, this versatility provides drilling companies the flexibility to upgrade their existing machinery without the need for significant capital investment.By utilizing the Mongoose Pro Shaker Screen, operators can expect improved efficiency in the solid separation process, resulting in cleaner drilling fluid and reduced waste disposal costs. The screen's superior performance also translates into a reduction in overall drilling time, driving profitability for organizations navigating increasingly competitive markets.Paragraph 6: Ensuring Quality and Safety StandardsMongoose Pro's commitment to quality and safety is evident in the rigorous testing and certification processes undergone by their shaker screens. Meeting and surpassing industry standards ensures the reliability and resilience of their products to withstand the demanding conditions experienced during drilling operations. This commitment to excellence has earned Mongoose Pro a well-deserved reputation for providing innovative, reliable, and high-performing drilling equipment.Paragraph 7: ConclusionWith the launch of the Mongoose Pro Shaker Screen, the oil and gas industry can now benefit from cutting-edge technology designed to enhance drilling efficiency, reduce costs, and promote environmental sustainability. As drilling operations become increasingly complex and competitive, equipping companies with advanced equipment such as the Mongoose Pro Shaker Screen will undoubtedly revolutionize the industry, driving progress and success into the future.

Top-quality Drilling Mud Centrifuge for Petroleum Drilling in China

China Petroleum Drilling Mud Centrifuge has become an essential tool in the oil and gas industry. It is used to remove solids from drilling mud, a crucial component in the drilling process. With the increasing demand for energy and the expansion of oil and gas exploration, the need for efficient and reliable centrifuge technology has never been greater.One of the leading providers of drilling mud centrifuges is a company with a proven track record in delivering high-quality products. With a commitment to innovation and excellence, they have been at the forefront of developing cutting-edge centrifuge technology for the oil and gas industry.The company's drilling mud centrifuge is designed to efficiently separate solids from the drilling mud, ensuring that the mud can be reused and recycled. This not only reduces waste but also minimizes the environmental impact of drilling operations. By incorporating advanced features and state-of-the-art technology, the centrifuge is able to achieve high levels of performance and reliability, even in the most demanding drilling environments.As one of the largest suppliers of drilling mud centrifuges in China, the company has established a strong reputation for delivering products that meet the highest standards of quality and reliability. Their centrifuges are widely used in drilling operations across the country and have earned the trust and confidence of their customers.The company's success can be attributed to its unwavering commitment to research and development. They invest heavily in the latest technologies and continuously strive to improve their products. This dedication to innovation has enabled them to stay ahead of the competition and deliver cutting-edge solutions to the oil and gas industry.In addition to their technological expertise, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific needs and provide tailored solutions that meet their requirements. This customer-centric approach has earned them a loyal customer base and a reputation for excellence in the industry.The company's drilling mud centrifuge is just one example of their commitment to driving the industry forward. With a focus on sustainability and efficiency, they are constantly exploring new ways to improve their products and processes. By partnering with leading oil and gas companies, they are able to gain valuable insights that inform their research and development efforts.Looking to the future, the company is poised to continue its growth and expansion. With a strong foundation built on innovation and customer satisfaction, they are well-positioned to meet the evolving needs of the oil and gas industry. As the demand for energy continues to rise, the company's drilling mud centrifuge will play a vital role in ensuring the efficiency and sustainability of drilling operations.In conclusion, China Petroleum Drilling Mud Centrifuge is an essential tool for the oil and gas industry. With a commitment to innovation, quality, and customer satisfaction, the company has established itself as a leading provider of drilling mud centrifuges in China. As the industry continues to evolve, their cutting-edge technology and dedication to excellence will be instrumental in driving the industry forward.

Efficient and Reliable Mud Gun Helps Boost Productivity in [Specific Industry]

Mud Gun Revolutionizes Drilling Operations in the Oil and Gas IndustryIn recent years, the oil and gas industry has been undergoing significant technological advancements to enhance drilling operations efficiency and safety. Among the leading innovators in this field is a renowned company, which has developed a groundbreaking solution called the Mud Gun, revolutionizing the way drilling operations are conducted.Designed to address the challenges associated with drilling mud circulation, the Mud Gun is a state-of-the-art device that enables efficient and effective cleaning, preventing hazardous situations and optimizing drilling operations. With its cutting-edge technology and user-friendly interface, it has become an essential tool for drilling companies worldwide.The Mud Gun combines durability, practicality, and versatility, making it the preferred choice for drilling operations. Its unique design allows for easy installation on drilling rigs and its robust construction ensures long-lasting performance even in the harshest drilling environments.One of the key features of the Mud Gun is its efficient mud circulation system. By using high-pressure jets, it effectively cleans the drilling mud, removing solid particles and maintaining its consistency. This process helps prevent blockages in the drilling equipment, reducing downtime and ensuring smooth operations.Furthermore, the Mud Gun's intelligent control system allows operators to monitor and adjust mud pressure and flow rate, providing real-time data that aids in decision-making and enhances drilling efficiency. The user-friendly interface of the Mud Gun enables operators to have better control over drilling operations, ensuring maximum productivity and safety.With safety being a top priority in the oil and gas industry, the Mud Gun is equipped with advanced safety features. The device is fitted with multiple sensors and alarms that detect potential malfunctions, leaks, or abnormal conditions, promptly notifying the operators and preventing accidents.The Mud Gun's outstanding performance has made it an indispensable tool for drilling companies across the globe. By ensuring proper cleaning and maintenance of drilling mud, it contributes to the longevity of drilling equipment, lowering maintenance costs and increasing the profitability of drilling operations.In addition to its exceptional performance, the Mud Gun is committed to minimizing its environmental impact. It incorporates eco-friendly technologies that reduce mud waste and contamination, ensuring compliance with environmental regulations and promoting sustainable drilling practices.As the oil and gas industry continues to evolve, the role of technology in enhancing drilling operations cannot be overstated. The Mud Gun has emerged as a game-changer, providing drilling companies with a reliable, efficient, and environmentally-friendly solution that optimizes drilling processes.Through continuous research and development, the company behind the Mud Gun remains committed to innovation and staying at the forefront of the industry. Their dedication to excellence and customer satisfaction has earned them a stellar reputation as a leader in the field, trusted by drilling professionals around the world.With its cutting-edge technology and exceptional performance, the Mud Gun has truly revolutionized drilling operations in the oil and gas industry. By offering a reliable solution that enhances efficiency, safety, and sustainability, it has become an indispensable tool for drilling companies globally. As technology continues to advance, the Mud Gun is undoubtedly a testament to the endless possibilities of innovation in the field of drilling operations.

SUS304 / 316L Material Milk Cream Separator Machine for Quality Dairy Processing

Title: Revolutionizing Dairy Processing: High-Quality Milk Cream Separator Machine Made in ChinaIntroductionIn today's fast-paced world, where dairy consumption is on the rise, the efficiency of dairy processing plants plays a crucial role in meeting the growing demand for milk, cream, and various dairy products. A critical component of these plants is the milk cream separator machine, which determines the quality and consistency of dairy products. In this blog, we will explore the significance of SUS304 and 316L material in dairy processing plants and shed light on China's contribution in developing top-notch milk cream separator machines. So, join us as we uncover the secrets behind China's innovation-driven dairy processing equipment!SUS304 and 316L Material: The Unyielding Pillar of QualityThe choice of material in dairy processing plants cannot be underestimated as it directly impacts the quality and hygiene standards of the final dairy products. SUS304 and 316L stainless steel materials are widely recognized for their excellent mechanical properties, corrosion resistance, and non-toxic nature. These materials ensure that the milk cream separator machine maintains optimal hygiene during the separation process and minimizes the risk of contamination. Moreover, SUS304 and 316L materials have exceptional heat resistance, safeguarding the quality of dairy products even at high temperatures. China-based manufacturers have recognized the importance of using such high-quality materials, ensuring durability and longevity of their milk cream separator machines.China's Contribution to Dairy Processing PlantsOver the years, China has emerged as a global manufacturing hub, offering high-quality dairy processing equipment, including milk cream separator machines. Chinese manufacturers have invested substantial resources in research and development, incorporating advanced technology and innovative designs into their machinery. With unparalleled precision and craftsmanship, China's milk cream separator machines have gained recognition worldwide for their superior performance and reliability.China Milk Separator: An Innovation-driven ChoiceWhen it comes to milk separator machines, China manufacturers have demonstrated their commitment to excellence by integrating cutting-edge technologies. These machines are equipped with advanced control systems, allowing for precise separation of milk and cream to achieve desired fat content variations. China milk separator machines are engineered to handle a wide range of milk volumes, ensuring efficient processing for dairy plants of all scales. The use of SUS304 and 316L materials ensures that these machines meet the highest quality and hygiene standards, guaranteeing safe and reliable dairy product production.Cream Milk Separator Machine: A Blend of Efficiency and QualityThe cream milk separator machines manufactured in China are designed to optimize the separation process, enhancing efficiency without compromising on quality. These machines employ innovative centrifugal force techniques, separating cream from milk with a high level of precision. The cream milk separator machines are known for their exceptional reliability, minimal maintenance needs, and maximized processing capacity, allowing dairy processing plants to meet consumers' demands efficiently.ConclusionAs the dairy industry continues to grow, the significance of high-quality milk cream separator machines cannot be overstated. China's commitment to engineering the finest dairy processing equipment, including milk separators and cream separators, has propelled the nation into a global leader in this sector. With the use of SUS304 and 316L materials, which ensure impeccable hygiene and durability, China manufacturers have revolutionized dairy processing plants worldwide. So, when it comes to choosing a milk cream separator machine, remember the keywords "China Milk Separator" and "Cream Milk Separator Machine" for reliable, efficient, and top-quality equipment.

Unlocking the Secrets of Mud Drilling: Everything You Need to Know

Title: Cutting-Edge Mud Drilling Technology Revolutionizes the Oil Extraction ProcessIntroduction:Innovation continues to shape the oil and gas industry as companies strive to improve efficiency and maximize production rates. We are excited to introduce a groundbreaking mud drilling technology, one that promises to revolutionize the oil extraction process. Developed by an industry-leading entity, this cutting-edge technology, referred to as MD-TECH (name disguised), has already garnered attention due to its potential to unlock new reservoirs and enhance the recovery of existing fields. This news article will delve into the features and advantages of this innovative mud drilling technology.1. Understanding MD-TECH:Developed after years of research and development, MD-TECH is a proprietary mud drilling technology that replaces traditional drilling techniques. It combines the use of advanced machinery and precisely engineered drilling muds to significantly enhance drilling and extraction processes.The unique selling point of MD-TECH lies in its ability to maintain precise control over both drilling pressure and characteristics of the drilling fluid. This high level of control ensures drilling operations are performed with accuracy, minimizing the risk of reservoir damage and improving overall efficiency.2. Unparalleled Advantages:MD-TECH offers numerous advantages over conventional drilling methods:a) Enhanced Safety: The technology's advanced sensors constantly monitor drilling operations, enabling quick response to any unexpected changes. This enhanced safety feature minimizes the risk of accidents and ensures drilling personnel can effectively manage potential emergencies.b) Superior Drilling Performance: The highly controlled drilling parameters provided by MD-TECH result in more accurate drilling paths, reducing the chances of deviation or accidental damage to the reservoir formation. This precision leads to increased well productivity and reduces the overall drilling time.c) Reduced Environmental Impact: By utilizing advanced drilling muds, MD-TECH significantly minimizes the environmental impact of drilling operations. These specially formulated muds are designed to reduce toxic emissions and prevent contamination of groundwater, ensuring a more sustainable and eco-friendly extraction process.3. Unleashing New Opportunities:The implementation of MD-TECH presents exciting new opportunities for the oil and gas industry. With its enhanced drilling capabilities, companies can explore previously untapped or hard-to-reach reservoirs.The technology's ability to minimize drilling-related damages allows for more extensive exploitation of existing reservoirs, including those with complex geological structures. This opens up a wealth of potential resources that were previously deemed too challenging or uneconomical to access.4. Global Implementation:Recognizing the immense potential of MD-TECH, our company has successfully deployed this technology in several drilling projects across the globe. Early results have been highly encouraging, showcasing the technology's ability to improve production rates and overall operational efficiency.The success of MD-TECH has also attracted interest from other industry players, who are keen to adopt this innovative drilling technology. Collaborations and partnerships are being forged to leverage its advantages and create a global platform for sharing knowledge and best practices.Conclusion:Innovation in the oil and gas sector is essential to address the growing demands for energy while minimizing environmental impact. MD-TECH, a revolutionary mud drilling technology, offers a unique solution to these challenges. With its precise control, increased safety measures, and reduced environmental impact, MD-TECH is set to reshape the oil extraction process, unlocking new reservoirs and maximizing production rates. Oil and gas companies worldwide stand to benefit from this cutting-edge technology, propelling the industry into a more efficient, sustainable, and prosperous future.