China Submersible Centrifugal and Mud Pump: Latest Developments

By:Admin

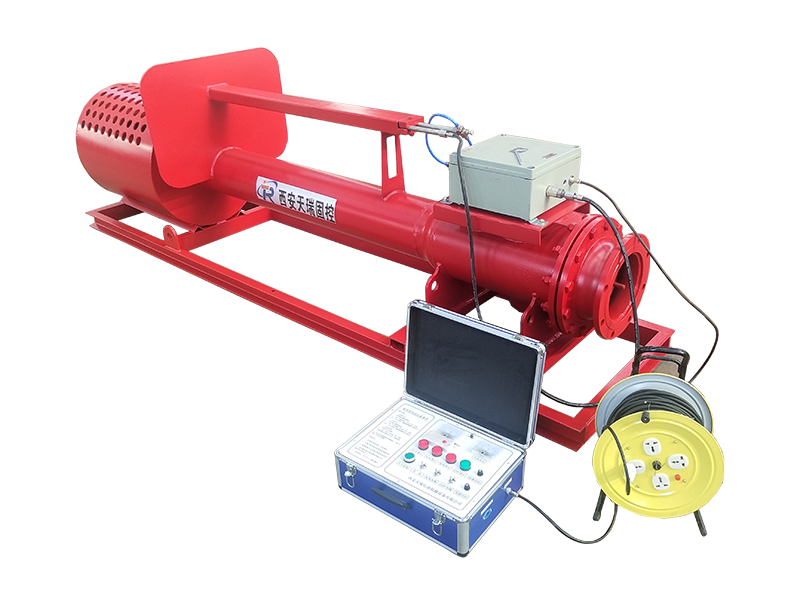

China has once again demonstrated its ability to lead the global pump industry with the development and production of innovative submersible centrifugal and mud pumps. These cutting-edge machines, designed to efficiently transport fluids and solid materials, have cemented China's position as a frontrunner in the international pump market.

The submersible centrifugal pump, a remarkable engineering feat manufactured in China, has garnered significant attention worldwide for its outstanding performance and reliability. Combining advanced technology and state-of-the-art design, this pump operates underwater, ensuring efficient fluid transportation in a variety of demanding applications.

Built for versatility, the submersible centrifugal pump is capable of handling various types of liquids, including water, oil, and chemicals. With its exceptional resistance to corrosion and wear, the pump can be used in industries such as oil and gas, mining, agriculture, and sewage treatment. Its ability to function effectively even in harsh and challenging environments has made it a go-to choice for projects worldwide.

Designed with simplicity and efficiency in mind, the submersible centrifugal pump requires minimal maintenance, reducing downtime and ensuring continuous operations. Equipped with powerful motors, this pump can deliver high flow rates and achieve impressive lift heights, making it an indispensable tool for projects requiring fluid transport over long distances.

Another breakthrough in China's pump industry is the submersible mud pump, which has revolutionized the handling of solid materials. This innovative pump is specifically designed for projects involving the transfer of sludge, slurry, and other viscous substances. With its outstanding ability to handle heavy solids, it has become an indispensable tool in diverse sectors, including construction, mining, and waste management.

The submersible mud pump's impressive capacity to transport large volumes of solid materials has greatly contributed to the efficiency and productivity of various industries worldwide. Its robust construction ensures durability and longevity even when subjected to rigorous operating conditions. By effectively eliminating the need for manual labor-intensive methods, such as shoveling and dredging, the submersible mud pump has significantly enhanced operational efficiency and reduced costs.

China's relentless pursuit of innovation and technological advancement has bolstered the country's reputation as a global leader in the pump industry. With their commitment to research and development, Chinese manufacturers have continued to introduce groundbreaking solutions that cater to the evolving needs of various sectors across the world.

The superior quality and reliability of Chinese submersible centrifugal and mud pumps have propelled their global market dominance. In recent years, China has emerged as the largest exporter of pumps, exporting to more than 190 countries and regions, attesting to the widespread recognition and acceptance of Chinese pump products. This prominence is primarily due to the country's ability to produce pumps of exceptional quality at competitive prices.

Furthermore, China's extensive investment in infrastructure development and its focus on sustainable solutions have created vast opportunities for the submersible centrifugal and mud pump industry. Growing demand from sectors such as construction, agriculture, and energy has buoyed the industry's growth and positioned Chinese manufacturers at the pinnacle of success.

Looking ahead, China's pump industry is poised to expand further, driven by continued advancements in technology and the growing global demand for efficient fluid handling solutions. With its unrivaled manufacturing capabilities, commitment to innovation, and ability to customize products to suit specific requirements, China is set to solidify its position as the undisputed leader in the submersible centrifugal and mud pump market.

As Chinese pump manufacturers continue to forge ahead with their pursuit of excellence, the global industry can expect to witness even greater advancements and remarkable achievements in the years to come.

Company News & Blog

Powerful Cyclone Desander Causes Devastation Across Affected Areas

Cyclone Desander: Revolutionizing Water Separation Technology[Company Name], a leading provider of innovative and sustainable solutions in the water treatment industry, is proud to introduce its latest product - Cyclone Desander. This revolutionary technology aims to significantly improve the efficiency and effectiveness of water separation processes, addressing the growing need for clean and purified water in various industries globally.Water scarcity and the increasing demand for clean water have become significant challenges in recent years. Industries such as oil and gas, mining, agriculture, and municipal wastewater treatment require efficient and reliable water separation solutions to extract impurities and contaminants from water sources. Existing technologies often fall short in terms of performance, energy consumption, and ease of maintenance. The Cyclone Desander aims to overcome these limitations and set new industry standards.The Cyclone Desander utilizes advanced hydrocyclone technology to remove solid particles from water streams. Unlike traditional separation methods, which rely on gravity or filters, this innovative system uses centrifugal force to separate sand, silt, and other particulates from water. The cyclonic action inside the device creates a high-velocity vortex, causing particles to be forced to the outer wall of the unit. The purified water then exits through the center, ensuring efficient and continuous separation.One of the primary advantages of the Cyclone Desander is its exceptional separation efficiency. The device can remove up to 98% of solid particles, regardless of their size and density. This high level of efficiency allows for cleaner water production, reducing the need for additional treatment steps and minimizing waste generation. The Cyclone Desander can handle a wide range of water volumes and pressures, making it adaptable to various industrial applications.In addition to its superior performance, the Cyclone Desander offers impressive energy savings. Traditional sediment separation methods often require large pumps and extensive power consumption, resulting in high operating costs. The Cyclone Desander, on the other hand, operates effectively at low pressure and with minimal energy requirements. By reducing energy consumption, companies can achieve significant cost savings and enhance their sustainability efforts.Furthermore, the Cyclone Desander is designed with ease of maintenance in mind. The unit features a removable cartridge that can be quickly accessed without the need for specialized tools or expertise. This user-friendly design ensures downtime is minimized during routine maintenance, allowing for uninterrupted water treatment operations.With its exceptional efficiency, energy savings, and ease of maintenance, the Cyclone Desander is poised to revolutionize the water separation industry. The device can be easily integrated into existing water treatment systems or utilized as a standalone solution. Its versatility makes it suitable for various applications, including oil and gas production, mining operations, as well as municipal wastewater treatment plants.[Company Name] is committed to providing sustainable solutions that meet the evolving needs of industries worldwide. The development and introduction of the Cyclone Desander reflects the company's dedication to innovation, efficiency, and environmental responsibility. By revolutionizing water separation technology, [Company Name] is enabling its clients to improve water quality, reduce operating costs, and contribute to a more sustainable future.As the demand for clean, purified water continues to rise, technologies like the Cyclone Desander will play a crucial role in addressing global water scarcity issues. With its exceptional performance, efficiency, and cost-effectiveness, the Cyclone Desander is set to become a game-changer in the water treatment industry.

A Guide to Understanding Centrifuges for Wine Production

Title: Revolutionary Centrifuge Technology Set to Transform Industrial ProcessesIntroduction (100 words):In an era driven by technological advancements, companies are constantly seeking innovative solutions to optimize industrial processes. One such breakthrough in centrifuge technology is set to revolutionize various sectors, including wastewater treatment, beverage manufacturing, and oil and gas extraction. The new Decanter Centrifuge, developed by an industry-leading company, promises enhanced efficiency, higher throughput, and remarkable precision. This article delves into the features and advantages of this cutting-edge centrifuge technology, highlighting its potential to disrupt existing practices and deliver significant benefits to businesses worldwide.1. The Need for Advanced Centrifuge Technology (150 words):Centrifugation is a widely used separation technique in multiple industries. It involves spinning a mixture rapidly, forcing the denser components to move towards the outer edge of the rotating vessel, thus facilitating separation. Despite its widespread application, traditional centrifuge devices have certain limitations that hinder efficiency and effectiveness. These drawbacks include limited throughput, high energy consumption, and difficulty in handling complex mixtures.To address these challenges, the development of a state-of-the-art Decanter Centrifuge has been undertaken. This advanced innovation boasts several critical improvements over conventional centrifuges, including enhanced separation efficiency, reduced energy consumption, and improved versatility. By combining cutting-edge engineering with intelligent automation, the Decanter Centrifuge aims to set new industry standards and become a game-changer in multiple sectors.2. Features and Technological Advancements (200 words):a) Enhanced Separation Efficiency: The Decanter Centrifuge employs a unique design that optimizes rotational speeds, G-forces, and dwell times, resulting in superior separation efficiency. This means that complex mixtures can be partitioned more effectively, leading to cleaner, more refined final products.b) Reduced Energy Consumption: The incorporation of advanced algorithms and sophisticated control systems in the Decanter Centrifuge ensures optimal energy utilization. By intelligently adjusting parameters such as feed flow, rotational speed, and load distribution, this groundbreaking technology significantly reduces energy consumption, helping businesses minimize their environmental footprint and operational costs.c) Versatility and Adaptability: The Decanter Centrifuge can handle a wide range of substrates and fluids, making it highly versatile for use in diverse industries. Its ability to operate at varying temperatures and pressures, coupled with customizable settings, allows for efficient processing of different materials, from heavy sludges to delicate biological suspensions.d) Intelligent Automation: The integration of advanced automation and smart controls streamlines operations, improves safety, and enhances precision. The Decanter Centrifuge can be remotely monitored and adjusted, reducing the need for manual intervention, and ensuring consistent and reliable performance.3. Potential Applications and Impacts (200 words):The groundbreaking Decanter Centrifuge technology holds immense potential to transform numerous industries and revolutionize key processes. Some notable applications include:a) Wastewater Treatment: By improving dewatering speed and separation efficiency, this centrifuge technology enables more efficient removal of solids from wastewater, enhancing treatment processes and reducing environmental impact.b) Beverage Manufacturing: The Decanter Centrifuge's ability to separate impurities and concentrate desirable components in beverages can enhance product quality and increase production yields. It ensures consistency and purity in various beverages, including juices, wines, and spirits.c) Oil and Gas Extraction: In the petroleum industry, the Decanter Centrifuge facilitates the separation of oil, water, and solids during drilling and production operations. This technology enables faster processing, reduces wastage, and enhances oil recovery rates.The widespread adoption of this advanced centrifuge technology is expected to deliver significant benefits to industries worldwide. Improved efficiency, reduced energy consumption, and enhanced product quality are just a few of the advantages that businesses can enjoy, leading to a more sustainable and profitable future.Conclusion (150 words):As businesses strive to streamline their operations and enhance productivity, the emergence of revolutionary technologies like the Decanter Centrifuge offers exciting possibilities. The advanced features and technological advancements incorporated in this cutting-edge centrifuge present an opportunity to transform industrial processes, surpassing the limitations of traditional devices.With its enhanced separation efficiency, reduced energy consumption, and compatibility with a diverse range of materials, the Decanter Centrifuge is poised to improve wastewater treatment, beverage manufacturing, and oil and gas extraction processes significantly. Beyond these industries, the potential for adoption in other sectors is vast, promising increased operational efficiency, reduced costs, and minimized environmental impact.As the world embraces innovative solutions, the Decanter Centrifuge is a clear testimony to the power of technology to reshape industries and drive progress. Its wide-reaching benefits ensure a brighter future for businesses seeking to optimize their processes and align with sustainability goals.

World-leading Manufacturer Provides Workover Drilling Rig Mud System for China Drilling Company

Title: Advancing Workover Drilling with GN Solids Control's Cutting-Edge Mud SystemIntroduction:As the global energy demands continue to rise, the drilling industry has witnessed a significant boost in workover operations to enhance production capabilities. To ensure the smooth execution of these drilling activities, China Drilling Company, a prominent player in the industry, turned to the expertise of GN Solids Control. With their cutting-edge workover drilling rig mud system, GN Solids Control is revolutionizing the industry, delivering exceptional separation efficiency and advanced technology. This blog post aims to delve deeper into the details of this groundbreaking system while discussing the importance of the China Drill Shale Shaker and Drilling Rig.GN Solids Control: A Leading Separation Equipment ManufacturerGN Solids Control has cemented its position as a world-leading manufacturer and supplier of solids and liquid separation equipment. With their commitment to customer satisfaction and relentless pursuit of innovation, GN Solids Control has successfully deployed numerous systems globally. The recent success in developing another set of workover drilling rig mud system highlights their dedication to delivering top-notch solutions tailored to specific customer requirements.Enhancing Workover Efficiency with GN Solids Control's Mud SystemThe workover process involves interventions in an existing well to optimize production by addressing various well-related issues. To maximize efficiency and minimize downtime during these operations, a well-designed mud system plays a crucial role. GN Solids Control's workover drilling rig mud system has been engineered to deliver outstanding performance, ensuring uninterrupted drilling operations.1. China Drill Shale Shaker:Among the essential components of GN Solids Control's mud system is the China Drill Shale Shaker. This innovative equipment applies mechanical separation to remove solid particles from drilling fluids. By efficiently separating the cuttings, the China Drill Shale Shaker not only minimizes wastage but also extends the lifespan of downstream equipment. This ensures a reduction in overall operational costs and boosts workover efficiency.2. Advanced Drilling Rig:In conjunction with the China Drill Shale Shaker, GN Solids Control's workover drilling rig mud system incorporates advanced drilling rig technology. The drilling rig serves as the core component of the system, facilitating the extraction of oil or gas reserves effectively. With enhanced features such as real-time monitoring, precise control system, and automation, these drilling rigs optimize overall workover performance.Unmatched Features and Benefits of GN Solids Control's Mud System:1. Higher Separation Efficiency:The cutting-edge technology incorporated in GN Solids Control's mud system enables efficient removal of solid particles from drilling fluids. This ensures consistent and reliable separation, leading to improved drilling performance and enhanced workover efficiency.2. Customized Design:GN Solids Control understands the unique requirements of each drilling project. Therefore, they offer tailor-made solutions to match specific operational demands. From system capacity to control mechanism, each component can be customized, providing China Drilling Company with the ideal workover drilling rig mud system.3. Increased Equipment Lifespan:GN Solids Control's mud system, equipped with the China Drill Shale Shaker, prevents clogging and damage to downstream equipment. By effectively removing the drilled cuttings, it helps extend the lifespan of crucial components, reducing maintenance costs and enhancing the longevity of the machinery.Conclusion:In the ever-evolving drilling industry, the need for efficient workover operations has become paramount. GN Solids Control's workover drilling rig mud system, featuring the China Drill Shale Shaker and advanced drilling rig technology, is the pinnacle of innovation in this field. By incorporating cutting-edge features and customizable design, this extraordinary mud system improves separation efficiency, boosts workover productivity, and elevates the overall drilling experience. With GN Solids Control's unrivaled expertise, China Drilling Company can now unlock new levels of productivity and profitability in their workover operations.

High-performing Shaker Screen for Efficient Mud Shale Shaker Operations

Title: Enhancing Drilling Efficiency with Cutting-Edge Mud Shale ShakersIntroduction:In the world of drilling operations, ensuring optimal performance and efficiency is imperative. One critical component that plays a crucial role in achieving these goals is the Mud Shale Shaker. As China's leading supplier of high-quality Shale Shakers, TR is at the forefront of providing top-notch equipment designed to revolutionize the drilling industry. In this blog post, we will delve into the innovative features of Mud Shale Shakers and their significant impact on drilling efficiency.1. The Role of Mud Shale Shakers:Mud Shale Shakers are indispensable devices used during the drilling process. They are responsible for separating drilling fluid or mud from the cuttings generated while drilling. The efficient removal of unwanted solids from the drilling mud is crucial as it helps maintain the drilling mud's properties, ultimately improving drilling performance.2. Introducing Cutting-Edge Technology:China-based TR has emerged as a leader in the shale shaker market by introducing advanced technology in the form of their Mud Shale Shakers. These state-of-the-art shakers are designed to enhance the efficiency and productivity of drilling operations. The incorporation of innovative features ensures a seamless separation process, contributing significantly to the overall success of any drilling project.3. Mongoose Shaker Screen - Revolutionizing the Industry:One of the standout features of TR's Mud Shale Shakers is the incorporation of the Mongoose Shaker Screen. This technologically advanced screen optimizes the separation process by efficiently removing cuttings from the drilling mud. The durable and high-quality construction of the Mongoose Shaker Screen allows for extended operation life, reducing downtime and maintenance costs.4. Unmatched Performance:TR's Mud Shale Shakers equipped with the Mongoose Shaker Screen are renowned for their exceptional performance. The unique design of the shaker screen ensures optimal vibration, enhanced cuttings conveyance, and increased throughput capacity. As a result, drilling efficiency is significantly improved, reducing overall drilling costs and maximizing resource utilization.5. Ensuring Quality and Reliability:As an established manufacturer and supplier, TR is committed to delivering products of the highest quality. Rigorous quality control measures are applied throughout the manufacturing process to ensure that the Mud Shale Shakers meet or exceed industry standards. TR's dedication to quality ensures that their shaker screens provide reliable and consistent performance in the most demanding drilling environments.6. Pioneering Green Initiatives:Environmental sustainability is a growing concern in the industry, and TR is addressing this issue head-on. The Mud Shale Shakers are designed to minimize waste generation by effectively capturing and separating solids. This eco-friendly approach helps reduce environmental impact while contributing to a greener and cleaner future.Conclusion:TR's Mud Shale Shakers have revolutionized the drilling industry with their cutting-edge technology and exceptional performance. The incorporation of the Mongoose Shaker Screen has proven to be a game-changer in optimizing drilling efficiency. As the leading Chinese manufacturer and supplier, TR continues to set industry standards by providing reliable and high-quality equipment that meets the diverse needs of drilling operations. By choosing TR's Mud Shale Shakers, drilling companies can significantly enhance their performance while contributing to a sustainable future.Keywords: China Mud Shale Shakers, Mud Shale Shaker, drilling efficiency, Mongoose Shaker Screen, TR, cutting-edge technology, drilling operations, drilling fluid, cuttings, shale shaker market, removal of solids, optimal vibration, throughput capacity, quality control measures, environmental sustainability, greener future.

China Submersible Centrifugal and Mud Pump: Latest Developments

China Submersible Centrifugal Pump and Submersible Mud Pump Spearhead Global Market DominanceChina has once again demonstrated its ability to lead the global pump industry with the development and production of innovative submersible centrifugal and mud pumps. These cutting-edge machines, designed to efficiently transport fluids and solid materials, have cemented China's position as a frontrunner in the international pump market.The submersible centrifugal pump, a remarkable engineering feat manufactured in China, has garnered significant attention worldwide for its outstanding performance and reliability. Combining advanced technology and state-of-the-art design, this pump operates underwater, ensuring efficient fluid transportation in a variety of demanding applications.Built for versatility, the submersible centrifugal pump is capable of handling various types of liquids, including water, oil, and chemicals. With its exceptional resistance to corrosion and wear, the pump can be used in industries such as oil and gas, mining, agriculture, and sewage treatment. Its ability to function effectively even in harsh and challenging environments has made it a go-to choice for projects worldwide.Designed with simplicity and efficiency in mind, the submersible centrifugal pump requires minimal maintenance, reducing downtime and ensuring continuous operations. Equipped with powerful motors, this pump can deliver high flow rates and achieve impressive lift heights, making it an indispensable tool for projects requiring fluid transport over long distances.Another breakthrough in China's pump industry is the submersible mud pump, which has revolutionized the handling of solid materials. This innovative pump is specifically designed for projects involving the transfer of sludge, slurry, and other viscous substances. With its outstanding ability to handle heavy solids, it has become an indispensable tool in diverse sectors, including construction, mining, and waste management.The submersible mud pump's impressive capacity to transport large volumes of solid materials has greatly contributed to the efficiency and productivity of various industries worldwide. Its robust construction ensures durability and longevity even when subjected to rigorous operating conditions. By effectively eliminating the need for manual labor-intensive methods, such as shoveling and dredging, the submersible mud pump has significantly enhanced operational efficiency and reduced costs.China's relentless pursuit of innovation and technological advancement has bolstered the country's reputation as a global leader in the pump industry. With their commitment to research and development, Chinese manufacturers have continued to introduce groundbreaking solutions that cater to the evolving needs of various sectors across the world.The superior quality and reliability of Chinese submersible centrifugal and mud pumps have propelled their global market dominance. In recent years, China has emerged as the largest exporter of pumps, exporting to more than 190 countries and regions, attesting to the widespread recognition and acceptance of Chinese pump products. This prominence is primarily due to the country's ability to produce pumps of exceptional quality at competitive prices.Furthermore, China's extensive investment in infrastructure development and its focus on sustainable solutions have created vast opportunities for the submersible centrifugal and mud pump industry. Growing demand from sectors such as construction, agriculture, and energy has buoyed the industry's growth and positioned Chinese manufacturers at the pinnacle of success.Looking ahead, China's pump industry is poised to expand further, driven by continued advancements in technology and the growing global demand for efficient fluid handling solutions. With its unrivaled manufacturing capabilities, commitment to innovation, and ability to customize products to suit specific requirements, China is set to solidify its position as the undisputed leader in the submersible centrifugal and mud pump market.As Chinese pump manufacturers continue to forge ahead with their pursuit of excellence, the global industry can expect to witness even greater advancements and remarkable achievements in the years to come.

China Separation Industries Discover the Excellence of Hydrocarbon Recovery Equipment in Solids Control Industries

As industries continue to grow in China, the need for efficient and effective separation equipment has become increasingly important. GN Solids Control, a leading manufacturer of drilling fluids recycling equipment, has expanded their offerings to include hydrocarbon recovery equipment, making them a standout in the separation industry.One of the key areas of focus for GN Solids Control is their solid liquid separator, which effectively removes solids from drilling fluids. This is crucial in the drilling process, as the removal of solids ensures that the drilling fluids can be reused and recycled, reducing waste and cutting down on costs.But GN Solids Control's product offerings go beyond just drilling fluids recycling equipment. Their 3-phase separation filter is another standout product that has garnered attention in the separation industry in China. This filter is designed to separate liquids and solids of different densities, as well as oil and water, making it ideal for use in a variety of industries.One of the biggest advantages of GN Solids Control's products is their efficiency. The solid liquid separator and 3-phase separation filter are designed to operate at a high processing rate, enabling customers to achieve greater productivity and throughput.But efficiency is only part of the equation. GN Solids Control's products are also designed with durability and reliability in mind. They are built to last, even in the harshest of operating conditions. This makes them an excellent investment for any business looking to streamline their operations and improve their bottom line.In addition to their high-quality products, GN Solids Control is known for their exceptional customer service and technical support. They have a team of experienced professionals who are dedicated to helping customers get the most out of their equipment. Whether they need assistance with installation, training, or ongoing maintenance, GN Solids Control is there to help every step of the way.Overall, GN Solids Control's hydrocarbon recovery equipment has made them a standout in the separation industry in China. Their solid liquid separator and 3-phase separation filter are both efficient and reliable, making them an excellent investment for any business in need of separation equipment. And with their exceptional customer service and technical support, customers can rest assured that they are in good hands with GN Solids Control.

Exploring the Immersive World of MUD: A Text-based Multiplayer Gaming Experience

In the world of gaming, there exists a unique type of game that is just as captivating as its counterparts, but is described entirely through text. We are talking about MUDs or Multi-User Dungeons. MUDs are fantastic virtual worlds that combine aspects of role-playing games, hack-and-slash games, interactive fiction, and online chat, to create a new type of gaming experience.In a MUD, players read descriptions of rooms, objects, and non-player characters in text form. With their imagination as their weapon, players can immerse themselves fully in a richly detailed environment where they can explore, battle, and interact with other players in real-time.One of the key features of MUDs is the ability to level up and acquire Mud equipment as players progress through the game. Mud equipment is any item or gear that a player can use to enhance their character and help them overcome greater challenges. This equipment can include powerful weapons, durable armor, magical artifacts, and useful consumables.The thrill of acquiring new Mud equipment is a significant motivator for players to continue playing MUDs. It not only improves their character’s abilities, but it also shows off their accomplishments to other players. With every level and piece of equipment gained, players become stronger and more capable of facing the toughest challenges that the game has to offer.In conclusion, MUDs are a unique and immersive gaming experience that offers a world of endless possibilities. With the ability to acquire Mud equipment, players are further incentivized to explore and interact with other players in ways they might not have imagined before. If you haven’t tried MUDs yet, give it a go and prepare to be amazed!

Top Quality Drill Rig Components for Efficient Drilling Rig Operations

China drilling rig parts and drill drilling rig drawworks are gaining recognition and popularity in the global market. These high-quality products have become a top choice for companies in need of reliable drilling equipment. With their advanced technology and excellent performance, they have managed to leave a lasting impression on customers worldwide.China is known for its vast manufacturing capabilities, and the drilling rig industry is no exception. The country has made significant progress in this sector and has established itself as a leading manufacturer and exporter of drilling rig parts and drawworks. Chinese companies have successfully filled the gap in the market with their superior products, offering cost-effective solutions to customers around the globe.One of the key players in this industry is a renowned Chinese company, recognized for its excellence in manufacturing drilling rig parts and drawworks. With a strong emphasis on research and development, this company has been able to produce cutting-edge products that meet the highest industry standards. Their commitment to innovation and continuous improvement has helped them stay ahead of the competition and maintain a strong market presence.Advanced technology lies at the core of these drilling rig parts and drawworks. Equipped with state-of-the-art features, they ensure smooth and efficient operations in drilling projects. The company's engineers and technicians work tirelessly to develop new and improved designs, integrating the latest technological advancements into their products. This focus on innovation has driven the company's success and positioned them as industry leaders.Quality is another aspect that sets these Chinese products apart from the competition. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every part and component meets the highest standards. Stringent inspection procedures and rigorous testing guarantee the reliability and longevity of their products. Customers can have peace of mind knowing that they are investing in top-notch equipment that will perform flawlessly on their drilling sites.In addition to their exceptional performance, these drilling rig parts and drawworks also offer great value for money. Chinese manufacturers are known for their competitive pricing, making their products an attractive choice for businesses looking to maximize their return on investment. The combination of affordability and quality has contributed to the growing demand for Chinese drilling rig equipment in the global market.Furthermore, the company's customer-centric approach is another factor that has fueled their success. They prioritize customer satisfaction and aim to establish long-term partnerships with their clients. By providing excellent after-sales service and technical support, they ensure that customers receive the assistance they need throughout the lifespan of their equipment. This commitment to customer care has earned them a loyal customer base and positive reputation.As awareness of the quality and reliability of China's drilling rig parts and drawworks continues to grow, more companies are turning to Chinese manufacturers for their drilling equipment needs. The country's dedication to innovation, emphasis on quality, competitive pricing, and customer focus have positioned them as key players in the global market. With their advanced technology and outstanding performance, Chinese drilling rig parts and drawworks are taking the industry by storm.In conclusion, China's drilling rig parts and drawworks have emerged as trusted and sought-after products in the global market. These high-quality and technologically advanced offerings have captured the attention of companies worldwide. With a commitment to innovation, stringent quality control, competitive pricing, and excellent customer service, Chinese manufacturers have secured their place as market leaders. As demand for drilling equipment continues to grow, China's contribution to the industry is set to remain significant.

Centrifugal Pump Supplier - High Quality Pump, Centrifugal Pump Manufacturers, Suppliers in China

Fuan Huawei Electrical Machinery Co., Ltd. – Your Trusted Centrifugal Pump SupplierCentrifugal pumps are widely used in industries that require fluid transport. These pumps are designed to move liquids through a piping system, with the help of a rotating impeller that applies centrifugal force to the fluid. Centrifugal pumps are essential equipment in industries such as chemical processing, water treatment, agriculture, and more.Fuan Huawei Electrical Machinery Co., Ltd. is a leading centrifugal pump supplier based in China. Founded in 2005, the company has been committed to providing customers with high-quality centrifugal pumps that meet their specific requirements.Fuan Huawei Electrical Machinery Co., Ltd. offers a wide range of centrifugal pumps for different applications, including single-stage pumps, multi-stage pumps, self-priming pumps, and more. The pumps are designed to handle different fluids, such as clean water, seawater, acidic or alkaline solutions, oil, and more.The company applies advanced technology and manufacturing techniques to produce efficient and durable centrifugal pumps. The pumps are made of high-quality materials such as stainless steel, cast iron, and copper, ensuring that they can withstand the toughest conditions. The impellers are precisely designed to maximize the pump's efficiency, reduce energy consumption and maintenance costs.Fuan Huawei Electrical Machinery Co., Ltd. has been certified by ISO9001:2015 Quality Management System, which ensures that the company meets international quality standards in their products and services. The company also provides professional technical support and customer service to help customers select the right pump for their needs.Centrifugal pumps have a wide range of applications. In the chemical industry, they are used to transport acids, bases, and other chemical solutions. In the oil and gas industry, they are used to transfer crude oil, refined products, and wastewater. In agriculture, they are used to irrigate farmlands and transport fertilizers. In the water treatment industry, they are used for pumping clean water, wastewater, and more.As a leading centrifugal pump supplier, Fuan Huawei Electrical Machinery Co., Ltd. has served customers in various industries around the world. The company has gained a reputation for providing reliable and high-quality pumps that meet industry standards and customer expectations. The company also offers customized solutions for customers with unique needs, ensuring that their pumps are tailored to their specific requirements.In conclusion, Fuan Huawei Electrical Machinery Co., Ltd. is a trusted centrifugal pump supplier that offers a wide range of efficient and durable pumps. The company's commitment to quality, innovation, and customer satisfaction has earned them a reputation as one of the leading pump suppliers in China. If you need a reliable and high-quality centrifugal pump for your application, Fuan Huawei Electrical Machinery Co., Ltd. is your go-to supplier.

Compact Mixing Tank: A Game-Changer for Efficient Mixing Processes

Small Mixing Tank Company Works to Revolutionize IndustryFor years, companies in the chemical and pharmaceutical industries have relied on large mixing tanks to produce their products, but a small startup called Small Mixing Tank (SMT) is looking to change that.SMT has developed a compact, customizable mixing tank that is perfect for companies that need a more efficient and cost-effective solution. Their tanks come in a range of sizes and are designed to fit in tight spaces, making them ideal for smaller facilities or production lines. In addition, SMT’s tanks are equipped with sophisticated mixing technology that ensures a uniform blend of materials and reduces waste.“Large mixing tanks can be a real headache for companies that have limited space or need to move their production lines around,” said SMT founder and CEO, Jane Smith. “That’s why we decided to develop a smaller, more versatile option that can be customized to meet the needs of any industry.”One of the key features of SMT’s tanks is their modular design. Companies can choose from a range of mixing heads and blades to create a tank that is tailored to their specific needs. This eliminates the need for companies to purchase multiple tanks for different applications, saving them time and money in the long run.“Our tanks are really a one-stop-shop solution,” said Smith. “From pharmaceuticals to food and beverage, our customers can create a mixing tank that meets the demands of their industry without having to invest in multiple tanks and accessories.”SMT’s tanks are also designed with cleaning and maintenance in mind. The tanks are easy to disassemble and clean, reducing the risk of contamination or cross-contamination. Additionally, the tanks’ components are all easily replaceable, so companies don’t have to worry about costly repairs or downtime if parts need to be replaced.“We know that time is money in manufacturing, so we wanted to make sure our tanks were designed for easy maintenance and cleaning,” said Smith. “This minimizes downtime and ensures that our customers can keep their production lines running smoothly.”Since launching in 2020, SMT has seen impressive growth and has attracted the attention of several major companies. Recently, the company received a significant investment from a leading pharmaceutical firm, which will allow them to expand their production capabilities and offer even more advanced mixing technology.“We’re thrilled to have the support of such a well-respected company in the pharmaceutical industry,” said Smith. “This investment will allow us to take our mixing technology to the next level and further revolutionize the industry.”Looking to the future, SMT plans to continue enhancing its mixing technology and expanding its product line to meet the needs of different industries. The company also plans to explore new markets and opportunities for growth, with a focus on sustainability and reducing waste.“We believe that our tanks have the potential to transform the manufacturing industry and help businesses of all sizes operate more efficiently and sustainably,” said Smith. “We’re excited to continue pushing the boundaries and developing new solutions that benefit both our customers and the planet.” In conclusion, Small Mixing Tank has established itself in the industry as a company that is dedicated to creating innovative solutions for businesses of all sizes. With its compact, modular design and advanced mixing technology, the company’s tanks have the potential to revolutionize the industry and help companies operate more efficiently and sustainably. As SMT continues to grow and expand, it will be interesting to see how it continues to push the boundaries of what is possible in manufacturing.