Exploring the Detrimental Effects of Drilling Waste and Its Environmental Impact

Title: Environmentally Sustainable Solution for Drilling Waste Introduced by Innovative CompanyIntroduction:In a groundbreaking development in the energy industry, a leading company () has unveiled a cutting-edge technology to address the pressing issue of drilling waste. With a steadfast commitment to environmental sustainability, this innovative solution promises to revolutionize how the industry handles waste disposal. By mitigating the harmful consequences of drilling activities, the company aims to contribute to a cleaner and greener future for the planet.Body:1. Understanding the Problem: - Drilling waste, a byproduct of oil and gas extraction, poses significant environmental challenges. - Contamination of soil, water bodies, and ecosystems due to improper disposal methods is a growing concern. - Traditional waste management techniques fall short in adequately handling the volume and toxicity of drilling waste.2. Introduction of a game-changing technology by (Company Name): - (Company Name) has developed a proprietary waste management solution that utilizes advanced technologies and innovative processes. - By combining state-of-the-art treatment methods and responsible disposal practices, the company ensures the elimination of harmful contaminants from drilling waste. - The technology also allows for the recovery and recycling of valuable materials from the waste, promoting a more circular economy.3. Key Features and Benefits of the Solution: - Advanced treatment processes: (Company Name) employs cutting-edge techniques, such as thermal desorption and centrifugation, to separate and treat drilling waste effectively. - Environmentally friendly: Through its technology, the company significantly minimizes the environmental impact caused by drilling waste, preventing contamination of soil and water sources. - Resource recovery: The innovative process results in the recovery of valuable materials, such as oil and minerals, which can be reused or repurposed, reducing the need for extraction of new resources. - Regulatory compliance: (Company Name) ensures strict adherence to local and international waste management regulations while providing a practical, efficient, and compliant waste disposal solution to the industry.4. Commitment to Sustainability: - (Company Name) is driven by a vision of promoting a sustainable future in the energy sector. - By addressing the drilling waste problem, the company actively contributes to reducing carbon footprint and supporting sustainable practices. - Through research and development, (Company Name) continues to innovate and enhance their technology, aiming for even greater efficiency and eco-friendliness.5. Collaboration and Impact: - (Company Name) acknowledges the importance of collaboration with industry stakeholders, environmental organizations, and governments to effectively tackle the drilling waste issue. - The implementation of their technology has already demonstrated a significant reduction in waste pollution, fostering a positive environmental impact. - The company actively engages with regulatory bodies, sharing expertise and knowledge to enhance waste management practices across the industry.6. Future Prospects: - With increased emphasis on sustainability, (Company Name) is poised to revolutionize the drilling waste management sector. - By showcasing the economic and environmental benefits of their solution, the company aims to gain wider acceptance and adoption across the industry. - Continued research and development efforts are underway to further enhance the efficiency and effectiveness of their technology.Conclusion:(Company Name)'s introduction of a technologically advanced waste management solution for drilling waste represents a significant stride toward environmental sustainability for the energy industry. By mitigating the harmful effects of drilling waste and promoting resource recovery, the company's innovative approach offers a transformative solution. With its commitment to collaboration and adherence to regulations, (Company Name) is poised to make a lasting impact in ensuring a cleaner and greener future.

Read More

Exploring the Immersive World of MUD: A Text-based Multiplayer Gaming Experience

In the world of gaming, there exists a unique type of game that is just as captivating as its counterparts, but is described entirely through text. We are talking about MUDs or Multi-User Dungeons. MUDs are fantastic virtual worlds that combine aspects of role-playing games, hack-and-slash games, interactive fiction, and online chat, to create a new type of gaming experience.In a MUD, players read descriptions of rooms, objects, and non-player characters in text form. With their imagination as their weapon, players can immerse themselves fully in a richly detailed environment where they can explore, battle, and interact with other players in real-time.One of the key features of MUDs is the ability to level up and acquire Mud equipment as players progress through the game. Mud equipment is any item or gear that a player can use to enhance their character and help them overcome greater challenges. This equipment can include powerful weapons, durable armor, magical artifacts, and useful consumables.The thrill of acquiring new Mud equipment is a significant motivator for players to continue playing MUDs. It not only improves their character’s abilities, but it also shows off their accomplishments to other players. With every level and piece of equipment gained, players become stronger and more capable of facing the toughest challenges that the game has to offer.In conclusion, MUDs are a unique and immersive gaming experience that offers a world of endless possibilities. With the ability to acquire Mud equipment, players are further incentivized to explore and interact with other players in ways they might not have imagined before. If you haven’t tried MUDs yet, give it a go and prepare to be amazed!

Read More

Efficient and Reliable Drilling Machines: Unveiling the Power of Drilling

[Company Name] Introduces Advanced Drilling Machine for Enhanced Drilling Operations[date][city, state] - In a bid to revolutionize drilling operations globally, [Company Name], a leader in the manufacturing of cutting-edge industrial machinery, announced the release of their latest drilling machine. The new technology promises to revolutionize the drilling industry by providing enhanced efficiency, versatility, and precision.Designed for both industrial and residential applications, the new drilling machine boasts state-of-the-art features that push the boundaries of current drilling capabilities. With its advanced technology and innovative design, [Company Name] aims to meet the growing demand for more efficient and productive drilling operations worldwide.The key feature of the new drilling machine is its advanced drilling technology, which allows for deeper and more precise drilling. Equipped with a powerful motor and specialized drill bits, this machine can effortlessly penetrate various materials, including concrete, metal, and wood. Its high torque capabilities ensure smooth operation even in the toughest drilling conditions.Additionally, the drilling machine incorporates intelligent automation features that increase operator safety and streamline operations. The inclusion of an automatic feed system ensures consistent drilling depth, negating the need for manual adjustments. This feature not only reduces operator workload but also minimizes drilling errors, resulting in better quality and reliable drilling outputs.Furthermore, the drilling machine offers exceptional versatility with its adjustable speed settings. Whether drilling delicate materials that require slow drilling or tackling heavy-duty tasks that demand high-speed drilling, this machine can cater to different drilling needs. This adaptability ensures that operators can achieve optimal results regardless of the drilling requirements, making it an ideal choice for various industries.In line with [Company Name]'s commitment to sustainability, the drilling machine incorporates eco-friendly features. With energy-efficient motors, reduced noise emissions, and ergonomic design, the machine helps minimize environmental impact while providing a comfortable working environment for operators. By prioritizing sustainability, [Company Name] aims to contribute to a greener future for the drilling industry.To ensure the seamless integration of the drilling machine into various drilling processes, [Company Name] provides comprehensive technical support and maintenance services. Their team of experienced engineers and technicians is readily available to assist clients with installation, training, and troubleshooting. This dedication to excellent customer service reinforces [Company Name]'s commitment to delivering not just top-notch products but also complete customer satisfaction."We are thrilled to introduce our latest drilling machine to the market," said [Spokesperson Name], a representative from [Company Name]. "We believe that this technology will revolutionize the way drilling operations are conducted, offering unparalleled efficiency and precision. We are confident that our clients will greatly benefit from this breakthrough in drilling technology."With its cutting-edge features, versatility, and dedication to sustainability, [Company Name]'s new drilling machine is set to make waves in the drilling industry. As the demand for more efficient drilling practices grows, this technology could pave the way for enhanced productivity and cost savings while reducing environmental impact. [Company Name] continues to drive innovation, setting its sights on transforming the drilling landscape on a global scale.Contact:[Company Name][Contact Person][Phone number][Email address][Website URL]

Read More

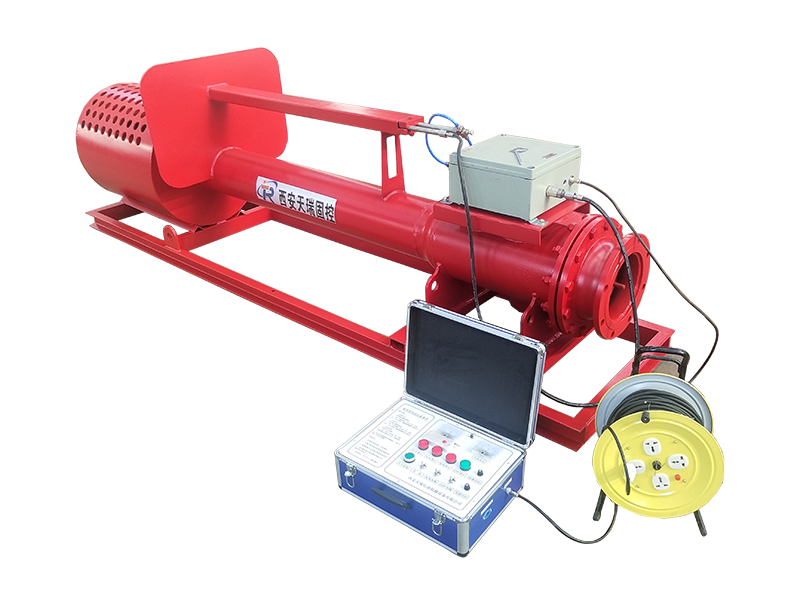

World-leading Manufacturer Provides Workover Drilling Rig Mud System for China Drilling Company

Title: Advancing Workover Drilling with GN Solids Control's Cutting-Edge Mud SystemIntroduction:As the global energy demands continue to rise, the drilling industry has witnessed a significant boost in workover operations to enhance production capabilities. To ensure the smooth execution of these drilling activities, China Drilling Company, a prominent player in the industry, turned to the expertise of GN Solids Control. With their cutting-edge workover drilling rig mud system, GN Solids Control is revolutionizing the industry, delivering exceptional separation efficiency and advanced technology. This blog post aims to delve deeper into the details of this groundbreaking system while discussing the importance of the China Drill Shale Shaker and Drilling Rig.GN Solids Control: A Leading Separation Equipment ManufacturerGN Solids Control has cemented its position as a world-leading manufacturer and supplier of solids and liquid separation equipment. With their commitment to customer satisfaction and relentless pursuit of innovation, GN Solids Control has successfully deployed numerous systems globally. The recent success in developing another set of workover drilling rig mud system highlights their dedication to delivering top-notch solutions tailored to specific customer requirements.Enhancing Workover Efficiency with GN Solids Control's Mud SystemThe workover process involves interventions in an existing well to optimize production by addressing various well-related issues. To maximize efficiency and minimize downtime during these operations, a well-designed mud system plays a crucial role. GN Solids Control's workover drilling rig mud system has been engineered to deliver outstanding performance, ensuring uninterrupted drilling operations.1. China Drill Shale Shaker:Among the essential components of GN Solids Control's mud system is the China Drill Shale Shaker. This innovative equipment applies mechanical separation to remove solid particles from drilling fluids. By efficiently separating the cuttings, the China Drill Shale Shaker not only minimizes wastage but also extends the lifespan of downstream equipment. This ensures a reduction in overall operational costs and boosts workover efficiency.2. Advanced Drilling Rig:In conjunction with the China Drill Shale Shaker, GN Solids Control's workover drilling rig mud system incorporates advanced drilling rig technology. The drilling rig serves as the core component of the system, facilitating the extraction of oil or gas reserves effectively. With enhanced features such as real-time monitoring, precise control system, and automation, these drilling rigs optimize overall workover performance.Unmatched Features and Benefits of GN Solids Control's Mud System:1. Higher Separation Efficiency:The cutting-edge technology incorporated in GN Solids Control's mud system enables efficient removal of solid particles from drilling fluids. This ensures consistent and reliable separation, leading to improved drilling performance and enhanced workover efficiency.2. Customized Design:GN Solids Control understands the unique requirements of each drilling project. Therefore, they offer tailor-made solutions to match specific operational demands. From system capacity to control mechanism, each component can be customized, providing China Drilling Company with the ideal workover drilling rig mud system.3. Increased Equipment Lifespan:GN Solids Control's mud system, equipped with the China Drill Shale Shaker, prevents clogging and damage to downstream equipment. By effectively removing the drilled cuttings, it helps extend the lifespan of crucial components, reducing maintenance costs and enhancing the longevity of the machinery.Conclusion:In the ever-evolving drilling industry, the need for efficient workover operations has become paramount. GN Solids Control's workover drilling rig mud system, featuring the China Drill Shale Shaker and advanced drilling rig technology, is the pinnacle of innovation in this field. By incorporating cutting-edge features and customizable design, this extraordinary mud system improves separation efficiency, boosts workover productivity, and elevates the overall drilling experience. With GN Solids Control's unrivaled expertise, China Drilling Company can now unlock new levels of productivity and profitability in their workover operations.

Read More

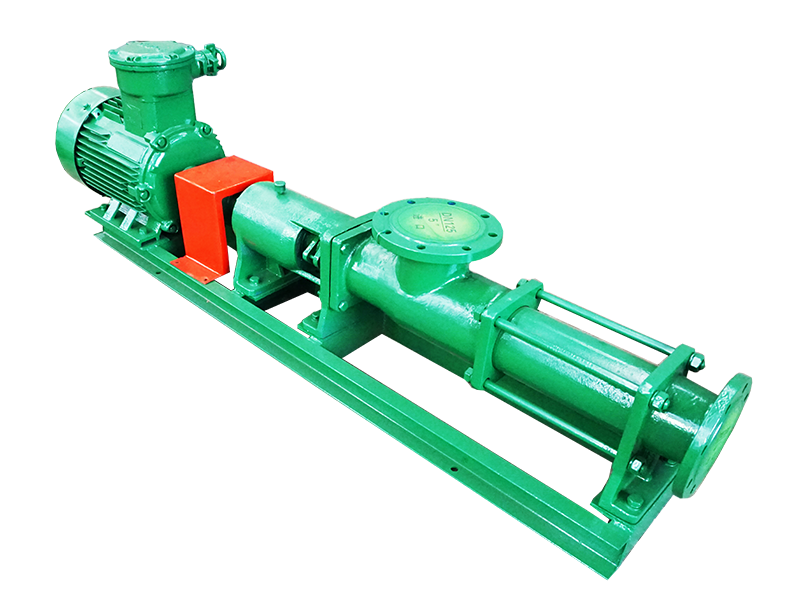

Powerful Mission and Magnum Pumps: A Closer Look at China's Latest Advancements

In recent news, China Mission Pump and Mission Magnum Pump have been making waves in the industry. These two pump manufacturers have been producing high-quality products that are known for their reliability, durability, and performance.China Mission Pump and Mission Magnum Pump are both subsidiaries of a larger company that has been in the pump-manufacturing business for over 20 years. They utilize cutting-edge technology and innovative design concepts in order to create pumps that are both efficient and effective.One of the main advantages of these two brands is that they offer a wide range of pumps for various applications. Whether you need a pump for agriculture, irrigation, mining, construction, or any other industrial purpose, there is a China Mission or Mission Magnum pump that will suit your needs.One of the key features of these pumps is their durability. Many of them are made with high-quality materials, such as cast iron, stainless steel, and other alloys, which makes them able to withstand even the harshest of conditions. They are also designed to be low maintenance, which makes them ideal for clients who want a product that will last for many years without requiring frequent repairs.Another advantage of these pumps is their high-performance levels. They are engineered to provide maximum efficiency and output, which means that they can handle large volumes of liquids, gases, and other fluids with ease. This makes them perfect for applications that require quick and efficient pumping, such as in mining, construction, or industrial processes.In addition to their high-performance levels, these pumps are also designed with user-friendliness in mind. Many models come equipped with features such as automatic controls, easy-to-use interfaces, and clear instructions, making them easy to operate even for those unfamiliar with the technology.More than just high-quality pumps, China Mission and Mission Magnum also provide exceptional customer service. They have a team of knowledgeable technicians and engineers who are available to provide support and guidance to clients who need it. This level of service ensures that clients can make the most out of their pumps, and that any concerns or issues can be resolved quickly and efficiently.In conclusion, China Mission Pump and Mission Magnum Pump are two of the most trusted pump brands on the market today. With their reputation for reliability, durability, and performance, they are the go-to choice for clients who demand only the best. Their wide range of products, high-tech features, and exceptional customer service make them an ideal choice for any industrial setting, from mining and construction to agriculture and irrigation.

Read More

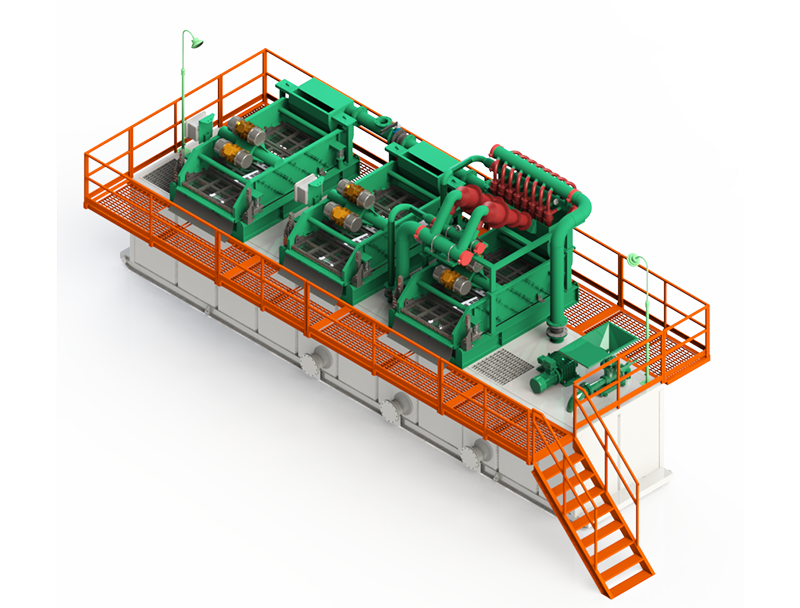

Importance of Mud Recycling Systems for Efficient Drilling Processes

GN Solids America Provides High-Quality Drilling Mud Recycling System with CE and ATEX StandardsThe drilling process is an essential part of oil and gas exploration, and the mud recycling system plays a vital role in maintaining the drilling mud properties at an optimal level. It removes the unnecessary large-sized solids and protects the drilling equipment from being damaged by large solids. GN Solids America is a leading provider of high-quality drilling mud recycling systems that meet Europe CE standard and ATEX explosion-proof standard.The mud recycling system consists of 2 centrifugal pumps, 2 mixing pumps, and 20 agitators. It acts as the heart and blood of the rig, making sure that all the components work together in perfect harmony. Without a reliable mud recycling system, the drilling process would be inefficient and expensive.GN Solids America is committed to providing its customers with the best quality solid control equipment at a competitive price. The shale shakers' G force can reach up to 8 G, making it possible to discharge drier solids that meet environmental requirements. Moreover, GN Solids America's new and upgraded shaker screen possesses better performance, longevity, and can store longer than ever before. During the drilling process, the shaker screens undergo significant wear and tear. Hence, GN Solids America's composite screen is the perfect solution, lasting longer than other screens.Customers from Europe and North America appreciate the quality of GN Solids America's products, and are buying them in increasing numbers. GN Solids America aims to provide its customers with the best quality products at an affordable cost."We are pleased to provide our customers with high-quality drilling mud recycling systems that meet CE and ATEX standards. We are committed to ensuring our customers' satisfaction by providing them with reliable and cost-effective products," said the spokesperson for GN Solids America.In conclusion, GN Solids America is a reliable provider of high-quality drilling mud recycling systems that meet international standards. Its products are top-notch and cost-effective, making them ideal for various applications in the oil and gas industry. GN Solids America's commitment to quality and customer satisfaction is what sets it apart from other solid control equipment providers in the market. Visit the website www.gnsolidsamerica.com. For more information, send your inquiries to [email protected].

Read More

Drilling Fluids Technology Training Course | Learn Online or In-Person at International Locations

and Training, Drilling Fluids Technology, Mobility Oil & Gas, online training, international training locations.Drilling Fluids Technology: Learn from the Best with Mobility Oil & GasDrilling fluids technology is a crucial aspect of any well drilling process. Whether it's a land-based or offshore drilling project, the right drilling fluid equipment and expertise are necessary for a successful outcome. This is where Mobility Oil & Gas comes in. The company provides comprehensive drilling fluids technology training courses both online and in-person.Mobility Oil & Gas is a leading provider of drilling fluids technology training courses in a variety of drilling-related areas. The company has several years of experience delivering cutting-edge drilling solutions for clients in the oil and gas industry. They have a team of highly trained professionals dedicated to providing industry-leading training and support to drilling professionals around the world.The drilling fluids technology training courses offered by Mobility Oil & Gas cover a wide range of topics, from basic to advanced. The company's instructors are experienced professionals with years of experience in their respective fields. They provide practical insights into the latest industry trends, equipment, and techniques. The courses are designed to meet the needs of professionals at all levels of expertise, from beginner to advanced.Mobility Oil & Gas provides its drilling fluids technology training courses both online and in-person. The online courses are a convenient option for busy professionals who may not be able to attend in-person training. The company employs cutting-edge technology to deliver its online courses in an interactive and engaging manner. Students can learn at their own pace and from the comfort of their homes or offices.In-person training courses are available at several international locations. Mobility Oil & Gas operates in many countries around the world, providing easy access to their training courses. The company has invested heavily in state-of-the-art training facilities that provide a hands-on approach to learning. Students get the opportunity to work with the latest drilling fluid equipment and techniques, ensuring that they are adequately prepared for real-world scenarios.The drilling fluids technology training courses provided by Mobility Oil & Gas are designed to meet the needs of companies of all sizes. Companies can choose to train their entire staff or select individuals they want to develop. The company provides customized training solutions tailored to the needs of each company. This ensures that companies get the maximum return on their investment in training.The drilling fluids technology training courses provided by Mobility Oil & Gas cover a range of topics, including the basics of drilling fluids, advanced drilling fluid equipment and techniques, and best practices for managing drilling fluids. The courses emphasize safety and environmental responsibility and aim at reducing the risks associated with drilling operations. The courses are designed to meet the needs of a diverse range of stakeholders, including drilling engineers, drilling supervisors, drilling fluids engineers, and other personnel involved in drilling operations.In conclusion, drilling fluids technology training is essential to the success of any drilling project. Mobility Oil & Gas provides industry-leading training courses designed to equip drilling professionals with the latest drilling fluid equipment and techniques. The company's courses are available both online and in-person and cover a range of topics. Companies of all sizes can benefit from Mobility Oil & Gas's customized training solutions, ensuring that their staff is adequately prepared for the challenges of drilling operations.

Read More

Efficient Mud Recovery System Delivers Exceptional Performance

Title: Innovative Mud Recovery System Revolutionizes Drilling Operations Introduction:As the demand for energy resources continues to rise, the drilling industry faces the pressing challenge of efficiently managing drilling waste while ensuring environmental sustainability. In response to this need, an innovative and game-changing technology, the Mud Recovery System (MRS), has emerged as a key solution. Developed by a cutting-edge company, this state-of-the-art system is transforming drilling operations worldwide, offering numerous benefits such as cost reduction, improved efficiency, and minimized environmental impact.Improved Drilling Efficiency:The Mud Recovery System (MRS) has revolutionized drilling operations by significantly improving drilling efficiency. The system incorporates advanced technology that enables the removal, cleaning, and re-usage of drilling mud, a crucial component in drilling operations. Traditionally, drilling mud is discarded after each use, leading to significant costs associated with procurement and disposal. However, with the MRS, drilling mud can be effectively cleaned, allowing for its reuse in subsequent drilling operations. This not only reduces the overall drilling costs but also ensures a continuous supply of high-quality drilling mud, thereby enhancing drilling efficiency.Cost Reduction:One of the most significant advantages of the Mud Recovery System is its ability to yield substantial cost savings for drilling companies. By eliminating the need to constantly procure new drilling mud, companies can significantly reduce their operational costs. Furthermore, the MRS also eliminates expenses associated with the transportation and disposal of drilling waste, which can be a significant financial burden. With the implementation of this innovative system, drilling companies can optimize their financial resources, potentially resulting in higher profit margins and greater financial stability.Enhanced Environmental Sustainability:Environmentally conscious practices have become a crucial aspect of drilling operations, with both regulators and public demanding sustainable approaches to drilling waste management. The Mud Recovery System plays a pivotal role in achieving these sustainability goals. The system reduces the overall disposal of drilling waste, eliminating the potential for environmental contamination. By cleaning and reusing drilling mud, the MRS minimizes the need for fresh excavation, preserving natural resources and reducing the ecological footprint associated with drilling operations. This sustainable approach not only protects the environment but also enhances the reputation of drilling companies as responsible corporate citizens.Versatility and Adaptability:The Mud Recovery System demonstrates its versatility and adaptability by being compatible with a wide range of drilling equipment. No matter the size or type of drilling rig, the MRS can seamlessly integrate into existing operations, without requiring major modifications or equipment replacements. Additionally, the system is flexible, allowing for customization based on specific drilling requirements. This adaptability ensures that companies can adopt the MRS technology without disrupting their current operations, enabling a smooth transition to a more efficient and sustainable drilling process.Operational Safety and Reliability:Safety is paramount in any drilling operation, and the MRS ensures the highest standards of operational safety. The system incorporates advanced filtration and separation techniques, effectively separating drilling mud from other waste materials. This process not only enhances the overall reliability and efficiency of the MRS but also ensures a safer working environment for drilling personnel. By reducing the volume of waste material, the risk of accidents and incidents is significantly reduced, safeguarding both human lives and the reputation of drilling companies.Conclusion:With the increasing need for sustainable and efficient drilling practices, the Mud Recovery System (MRS) emerges as a game-changer in the drilling industry. Through its innovative cleaning and reusage capabilities, the MRS offers significant cost reductions, enhanced drilling efficiency, and improved environmental sustainability. This versatile and adaptable system guarantees safety and reliability, revolutionizing drilling operations worldwide. As companies strive for effective waste management and environmentally responsible practices, the Mud Recovery System undoubtedly presents itself as a pioneering solution, ensuring a greener and more profitable future for the drilling industry.

Read More

How a Centrifuge Improves Drilling Fluid Performance

Title: Cutting-Edge Drilling Fluid Centrifuge Revolutionizes Oil and Gas IndustryIntroduction:In the fast-paced and ever-evolving world of oil and gas operations, technological advancements play a crucial role in improving efficiency, reducing costs, and enhancing environmental sustainability. A groundbreaking innovation in this field comes in the form of the ultra-modern Drilling Fluid Centrifuge, introduced by a leading industry player. This cutting-edge centrifuge, equipped with state-of-the-art features, is poised to revolutionize the drilling processes, particularly in terms of waste management and fluid-recycling capabilities.[Company Name], a renowned provider of oil and gas solutions, has recently unveiled its flagship Drilling Fluid Centrifuge, designed to deliver high-quality separation efficiency while ensuring reduced environmental footprint. With a vast array of pioneering features and unparalleled performance, this centrifuge is poised to become an indispensable asset for oil and gas companies worldwide.Highly Efficient Separation:The Drilling Fluid Centrifuge boasts an advanced design that enables efficient separation of drilling fluids from solid particles. This enables operators to recover greater volumes of valuable drilling fluids, reducing associated costs significantly. The centrifuge employs cutting-edge technology to maximize separation efficiency, resulting in improved productivity and reduced downtime. By effectively removing solid particles, it ensures that the drilling fluids can be effectively reutilized, leading to substantial cost savings.Advanced Waste Management:One of the standout features of this centrifuge is its exceptional waste management capabilities. By swiftly eliminating solid waste, the centrifuge curtails the amount of drilling waste generated, thereby positively impacting the environment. With an increasing emphasis on environmental sustainability, the Drilling Fluid Centrifuge offers a viable solution to effectively manage and reduce waste production during drilling operations.In addition to minimizing environmental impact, this innovative centrifuge also enhances occupational safety. By efficiently removing hazardous solids from drilling fluids, it reduces the potential health risks faced by workers and ensures a safer work environment. [Company Name]'s centrifuge prioritizes the well-being of both workers and the environment, making it an invaluable asset in the oil and gas sector.User-Friendly Interface and Dependability:The Drilling Fluid Centrifuge sports a user-friendly interface, allowing operators to easily monitor and control critical parameters during the separation process. The interface provides real-time data on variables such as flow rates, pressure differentials, and fluid level, empowering operators to make prompt adjustments. This feature ensures that the centrifuge operates optimally, maximizing productivity and efficiency throughout the drilling operation.Furthermore, [Company Name]'s Drilling Fluid Centrifuge is constructed with premium quality materials, guaranteeing exceptional durability and reliability. Designed to withstand harsh operating conditions, this centrifuge offers extended service life, resulting in reduced maintenance and replacement costs. Its robustness and dependability make it an attractive investment choice for oil and gas companies seeking long-term solutions.Conclusion:As oil and gas companies continually strive for enhanced operational efficiency and reduced environmental impact, products like [Company Name]'s Drilling Fluid Centrifuge are instrumental in shaping the future of the industry. With its advanced separation capabilities, waste management features, user-friendly interface, and durability, this centrifuge is a game-changer. It not only enhances productivity and cost-effectiveness but also underscores the sector's commitment to sustainability and safety.As the demand for oil and gas continues to rise, the Drilling Fluid Centrifuge stands as a beacon of innovation, offering unprecedented value to oil and gas operations worldwide. Its introduction into the market represents a significant step forward, revolutionizing drilling processes and setting new industry standards.

Read More

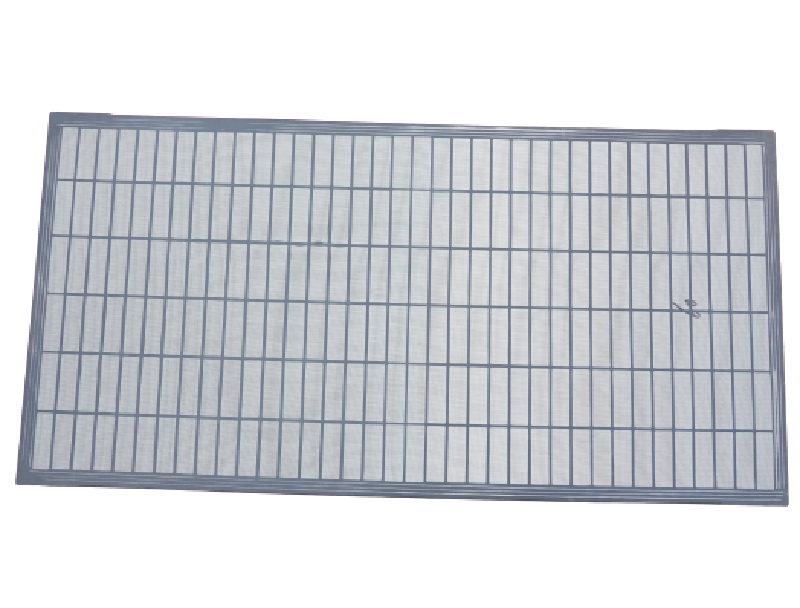

China Expands Shale Shaker and Drilling Rig Capabilities, Boosting Oil Extraction Efforts

China Drill Shale Shaker and Drilling Rig Manufacturing Company Strengthens Position in Global MarketChina's drill shale shaker and drilling rig manufacturing industry is steadily growing, with one prominent company leading the charge. Operating at the forefront of innovation, this company has successfully established itself as a key player in the global market. With a diverse range of products and a commitment to quality, they continue to pave the way for the future of drilling technology.Driven by a dedication to meeting the evolving needs of the industry, this Chinese company has adopted a customer-centric approach, focusing on delivering cutting-edge solutions tailored to their clients' specific requirements. By combining advanced technology with extensive research and development, they have been able to create industry-leading drilling equipment that excels in performance, reliability, and cost-effectiveness.The company's flagship product, the shale shaker, has become renowned for its superior efficiency in separating solids from drilling fluid, thus optimizing the drilling process. Utilizing a high-frequency vibration system, the shale shaker effectively removes unwanted debris, ensuring the smooth operation of drilling rigs in even the most challenging environments. With a strong emphasis on durability, this product showcases the company's commitment to quality, enabling customers to increase operational efficiency and reduce maintenance costs.In addition to shale shakers, the company also offers a wide range of drilling rigs that are designed to meet the diverse needs of the industry. These rigs are equipped with state-of-the-art hydraulic systems, advanced control panels, and user-friendly interfaces, allowing for precise control and ease of operation. Combined with their exceptional durability, these drilling rigs offer an unmatched level of performance, enabling operators to tackle demanding drilling projects with ease.Recognizing the importance of sustainability and environmental conservation, this Chinese company has also made significant strides in developing eco-friendly drilling solutions. By incorporating energy-efficient technologies and reducing emissions, they aim to minimize the environmental impact of drilling operations while ensuring optimal performance.A key contributing factor to the company's success lies in their comprehensive after-sales support system. With a global network of service centers, they offer timely assistance, technical advice, and spare parts supply, ensuring that customers receive prompt and reliable support throughout the lifespan of their equipment. This commitment to customer satisfaction has garnered them an excellent reputation and a loyal customer base, further solidifying their position in the industry.Having established a strong presence in the domestic market, the company has set its sights on expanding its reach globally. With an increasing demand for their products in various regions, they have successfully exported their drilling equipment to numerous countries, earning international acclaim for their quality and performance. By actively participating in international exhibitions and establishing partnerships with distributors worldwide, they continue to strengthen their position and gain recognition on a global scale.The success of China's drill shale shaker and drilling rig manufacturing industry is undoubtedly bolstered by this prominent Chinese company. With their commitment to innovation, customer satisfaction, and environmental responsibility, they are set to lead the way in the global market. As drilling technology continuously evolves, this company remains at the forefront, ensuring that they are continuously delivering cutting-edge solutions that exceed customer expectations.

Read More