Top Shale Shaker Options for Oil Drilling in China

By:Admin

The oil drilling industry in China is set to experience a significant upgrade with the introduction of advanced shale shaker technology. This enhancement is made possible through a collaboration between China Shale Shaker and a leading provider of drilling equipment. The implementation of this new shale shaker technology is expected to revolutionize the oil drilling process in China, bringing about increased efficiency and productivity.

Shale shakers are an essential piece of equipment in the oil drilling industry, used for separating drilling cuttings from drilling fluid. This process is crucial in maintaining the integrity of the drilling fluid and ensuring the smooth operation of the drilling rig. With the introduction of advanced shale shaker technology, China's oil drilling industry is poised to take a leap forward in terms of operational efficiency and environmental impact.

The new shale shaker technology boasts several key features that set it apart from traditional equipment. One such feature is its advanced vibration system, which enables the shale shaker to effectively separate solid particles from drilling fluid. This results in a significant reduction in the amount of waste generated during the drilling process, contributing to a more sustainable and environmentally friendly operation.

Furthermore, the introduction of this advanced shale shaker technology brings with it a significant improvement in overall operational efficiency. With its enhanced capabilities, the new shale shaker is able to process drilling cuttings at a much faster rate, leading to a more streamlined drilling operation. This increase in efficiency not only translates to time and cost savings but also has a positive impact on the overall productivity of the drilling process.

In addition to these operational benefits, the new shale shaker technology also prioritizes ease of maintenance and servicing. With a user-friendly design and simplified maintenance procedures, the equipment is set to minimize downtime and reduce the need for extensive technical support. This is particularly advantageous in the context of China's oil drilling industry, where the demand for reliable and low-maintenance equipment is paramount.

The collaborative effort between China Shale Shaker and the drilling equipment provider underscores a commitment to innovation and excellence within the oil drilling industry. By leveraging each other's expertise and resources, the two companies are at the forefront of driving technological advancement in China's oil drilling sector.

Furthermore, the partnership between China Shale Shaker and the drilling equipment provider reflects a broader trend within the industry towards collaboration and knowledge-sharing. As the oil drilling industry continues to evolve, partnerships such as these are becoming increasingly important in driving progress and innovation.

The introduction of advanced shale shaker technology in China's oil drilling industry has the potential to bring about a transformative change. Not only does it signify a significant step forward in terms of operational efficiency and environmental impact, but it also serves as a testament to the industry's ongoing commitment to advancement and improvement.

Looking ahead, the implementation of this new technology is expected to set a new standard for shale shaker equipment in China's oil drilling industry. With its advanced capabilities and enhanced performance, the new shale shaker technology is poised to redefine the way drilling operations are conducted, ultimately paving the way for a more efficient, sustainable, and productive industry.

In conclusion, the introduction of advanced shale shaker technology in China's oil drilling industry represents a significant milestone in the ongoing evolution of the sector. By leveraging the expertise and resources of China Shale Shaker and the drilling equipment provider, the industry is primed for a new era of efficiency, productivity, and environmental responsibility. This collaboration serves as a testament to the industry's commitment to innovation and progress, and signals a promising future for oil drilling in China.

Company News & Blog

Upgraded pneumatic agitators with 15:1 gear drive reducer for improved efficiency and lower air consumption

Binks, a leading manufacturer of fluid handling equipment based in Glendale Heights, Illinois, has recently announced an upgrade to their pneumatic agitators. The new agitators feature a more efficient 15:1 worm gear drive reducer, replacing the previous 20:1 ratio. This upgrade allows for reduced air consumption while maintaining the desired mixing speeds.The upgraded agitators are designed for use with various containers such as pails, drums, and pressure tanks. They are suitable for a range of applications in industries such as coatings, adhesives, sealants, and other fluid-based manufacturing processes. The new units are available in both fixed speed and variable speed models.One of the key advantages of the new 15:1 worm gear drive reducer is the reduction in air consumption. By optimizing the gear ratio, Binks has succeeded in achieving the desired mixing speeds with less air pressure and consumption. This improvement not only saves energy but also reduces operational costs for users.The variable speed model offers additional benefits by allowing users to adjust the mixing speed according to their specific requirements. With variable speed control, operators have greater flexibility and control over their mixing processes, ensuring consistent and precise results.Binks, known for its innovation and commitment to providing high-quality products, has also introduced a brand-new fluid agitator in conjunction with these agitator upgrades. The fluid agitator incorporates the latest technology and features to enhance the mixing process further.The fluid agitator comes equipped with advanced mixing blades, designed to optimize the mixing efficiency and homogeneity of the fluids. These blades, combined with the upgraded agitator's reduced air consumption, enable users to achieve superior mixing performance and product quality.Additionally, the fluid agitator boasts a user-friendly design, allowing for easy installation and maintenance. Its robust construction ensures durability, making it suitable for demanding industrial environments. With features like quick-release clamps and seals, operators can conveniently access the agitator's components for cleaning and maintenance purposes, minimizing downtime and maximizing productivity.Binks is proud to offer these upgraded pneumatic agitators and the new fluid agitator as part of their commitment to meeting the evolving needs of their customers. With a legacy of over 130 years in the industry, the company has continuously focused on developing innovative solutions to improve fluid handling processes and deliver exceptional performance.Clients across various industries can now benefit from the reduced air consumption, improved mixing efficiency, and user-friendly design offered by these upgraded agitators. Whether it's for small-scale operations or large-scale manufacturing, Binks provides reliable and efficient agitators that meet the highest industry standards.In conclusion, Binks' upgraded pneumatic agitators with the more efficient 15:1 worm gear drive reducer offer improved performance and reduced air consumption. The variable speed model allows for greater control and flexibility, catering to a wide range of mixing requirements. The introduction of the new fluid agitator complements these upgrades, providing advanced mixing technology and user-friendly features. With these enhancements, Binks continues to be at the forefront of delivering innovative solutions for efficient fluid handling in various industries.

Effective Waste Management Strategies for a Cleaner Environment

[Title]: Industry Leader Revolutionizes Waste Management Practices[Introduction]:In recent years, the waste management industry has faced mounting challenges due to increasing waste volumes, environmental concerns, and the need for more efficient and sustainable solutions. However, under the visionary leadership of an industry stalwart, significant progress has been made in revolutionizing waste management practices. This article will shed light on the achievements, initiatives, and impact of this pioneering company, utilizing the anonymous name "Sustainable Waste Solutions" throughout.[Body]:1. Introduction to Sustainable Waste Solutions:Sustainable Waste Solutions (SWS), an influential player in the waste management sector, has been at the forefront of innovation and sustainable practices. Established in [year], SWS has gradually built a reputation for its commitment to environmental stewardship, cutting-edge technology, and community engagement.2. Expanding Recycling Programs:Recognizing the importance of recycling in reducing landfill waste, SWS has spearheaded a comprehensive and inclusive program that goes beyond traditional recycling methods. By implementing co-mingled recycling programs, SWS has simplified the recycling process and made it more convenient for customers. Furthermore, the company has invested in state-of-the-art sorting technology, ensuring that recyclables are efficiently processed and effectively recycled.3. Waste-to-Energy Initiatives:SWS understands the potential of waste-to-energy solutions in producing renewable energy while minimizing landfill usage. With this in mind, the company has launched several waste-to-energy initiatives, including the establishment of innovative facilities that convert waste into electricity or biogas. SWS has successfully partnered with local energy providers, contributing to the reduction of greenhouse gas emissions and the diversification of the energy mix.4. Collaboration with Local Communities:Involving local communities in waste management practices is crucial for long-term success. SWS has actively engaged with communities, offering educational programs and interactive workshops to raise awareness about waste reduction, recycling techniques, and sustainable living practices. Additionally, the company has sponsored various community cleanup events, fostering a sense of ownership while promoting eco-conscious behaviors.5. Technological Advancements:Recognizing the vital role of technology in waste management, SWS has made significant investments in innovative solutions. By deploying advanced waste management systems, such as smart bins and collection trucks equipped with sensors, the company has optimized waste collection routes, reduced operational costs, and enhanced overall efficiency. Furthermore, SWS has developed customized waste management software, allowing customers to track their waste generation and make informed decisions about recycling and waste reduction.6. Long-term Environmental Goals:Sustainable Waste Solutions has set ambitious environmental goals to reduce its carbon footprint and contribute to a more sustainable future. By [year], the company aims to achieve a [percentage] reduction in landfill waste, a [percentage] increase in recycling rates, and a [percentage] reduction in greenhouse gas emissions. SWS plans to achieve these targets through continuous innovation, strategic partnerships, and an unwavering commitment to sustainable practices.7. Awards and Recognition:The remarkable efforts of Sustainable Waste Solutions have not gone unnoticed, as the company has received numerous awards and accolades for its exceptional performance and dedication to environmental preservation. These accolades have further cemented SWS's position as an industry leader and have encouraged other waste management entities to adopt similar practices.[Conclusion]:Sustainable Waste Solutions has undoubtedly reshaped the waste management landscape by introducing innovative practices, engaging local communities, and prioritizing sustainability. As the company continues to inspire and lead the way, it is expected that the waste management industry will undergo significant transformation, ultimately resulting in a cleaner, greener, and more sustainable future.

Mud Hoppers: The Key to Successful Outdoor Adventure

Innovative Mud Hopper Revolutionizes Drilling OperationsDrilling operations have long been an essential component of various industries, such as oil and gas exploration, mining, and construction. However, the efficiency and effectiveness of these operations have often been hindered by the difficulties encountered in mud mixing and circulation processes. To address these challenges, a pioneering solution has been unveiled – the new generation Mud Hopper developed by an industry-leading company.(Note: The brand name has been removed for compliance with guidelines.)The Mud Hopper represents a significant breakthrough in drilling technology, offering a compact, efficient, and user-friendly solution for mud mixing and circulation. Its state-of-the-art design and advanced features simplify drilling operations, enhancing productivity, and reducing costs.The company behind this innovative technology has been a frontrunner in the drilling equipment industry for over two decades. Known for their commitment to constant innovation and customer-centric approach, they have gained a reputation for delivering high-quality equipment that meets the evolving needs of the industry.Their latest masterpiece, the Mud Hopper, is designed to streamline the mud mixing process, which is crucial for maintaining drilling fluid density and ensuring efficient drilling operations. With its compact size and versatile features, the Mud Hopper offers numerous advantages over conventional mud mixing equipment.One of the standout features of the Mud Hopper is its ability to handle a wide range of drilling fluids, including bentonite, polymers, and various additives. This flexibility allows operators to adapt to different drilling conditions, optimizing the performance of their drilling operations. Moreover, the Mud Hopper's automated mixing capabilities eliminate human error, ensuring consistent and accurate results every time.Furthermore, the Mud Hopper boasts an intuitive control panel, making it incredibly easy and convenient for operators to monitor and adjust mud properties in real-time. This user-friendly interface, combined with its compact and portable design, allows for seamless integration into drilling operations of any scale or location.The Mud Hopper's efficient circulation system ensures a constant supply of properly mixed drilling fluid to the drilling operation. This circulation process is vital for flushing cuttings, stabilizing boreholes, and maintaining optimal downhole pressure. By eliminating the need for manual mixing and reducing downtime associated with maintenance, the Mud Hopper significantly increases operational efficiency and overall productivity.Another noteworthy advantage of the Mud Hopper is its focus on environmental sustainability. The equipment's intelligent design minimizes mud wastage and reduces the need for excessive chemical additives. This not only reduces costs for operators but also contributes to a greener and cleaner drilling environment.The company's commitment to quality and customer satisfaction extends beyond the equipment itself. They offer comprehensive support services, including installation assistance, training programs, and a reliable after-sales service network. This holistic approach ensures that operators can maximize the benefits of the Mud Hopper and minimize any potential disruptions to their operations.As the drilling industry continues to evolve and adapt to increasingly complex challenges, innovative solutions like the Mud Hopper play a vital role in improving operational efficiency and sustainability. By revolutionizing the mud mixing and circulation processes, this cutting-edge equipment allows drilling companies to overcome traditional limitations and achieve greater success in their operations.In summary, the Mud Hopper, developed by a leading drilling equipment company, is a game-changer for the industry. Its compact design, automated mixing capabilities, and user-friendly interface make it a valuable addition to drilling operations of any scale. By optimizing mud mixing and circulation processes, the Mud Hopper enhances efficiency, reduces costs, and contributes to a greener and more sustainable drilling environment. With their continued commitment to innovation and customer satisfaction, the company behind the Mud Hopper is poised to shape the future of drilling operations.

High-Quality Linear Motion Drilling Rigs Shale Shaker with 120 M3/H Capacity: API Standard

Exploring the Benefits of China Shale Shaker and Oli Drilling Shale ShakerDrilling rigs are crucial in the process of oil and gas exploration. These rigs help extract valuable resources from the earth's surface. In recent years, there has been a surge in the demand for shale shakers as they play a vital role in the extraction process. Shale shakers separate the solids and liquids that come out of the drilling process, and the extracted fluid is then transferred to other areas for further processing.China Shale Shaker is one of the top-quality shale shakers available in the market today. This shale shaker is designed for high-performance industrial applications and is built with top-of-the-line components that meet API standards, making it a popular choice for drilling projects worldwide. With a 120 M3/H capacity, this linear motion drilling rig shale shaker is an exceptional piece of equipment that performs exceptionally well. Its superior screening capabilities and efficient operation make it a valuable asset for any job site.Apart from its high-quality performance, China Shale Shaker promises users long-lasting durability and reliability. The equipment is also built to withstand harsh weather and environmental conditions often found in drilling sites. Furthermore, its design ensures easy maintenance, meaning that the machinery can operate efficiently throughout its lifespan with little downtime.Another high-quality product is the Oli Drilling Shale Shaker. This shale shaker is well known for its innovative design and superior performance capabilities. The Oli Drilling Shale Shaker employs a sophisticated screening process, allowing for better separation of solids from liquid drilling fluid. This process results in better productivity levels during the extraction process, with less wastage reported from the operation.The Oli Drilling Shale Shaker is built to meet all API standards, and its components are sourced from reputable brands to ensure high performance and longevity. Its structure is designed to handle challenging environments and rugged conditions that drilling sites often pose.Apart from its outstanding performance capabilities, the Oli Drilling Shale Shaker is also user-friendly, with easy-to-use controls that reduce downtime and increase operational efficiency. The maintenance of this equipment is also hassle-free, further enhancing its durability and reliability.In conclusion, drilling rigs are vital in the oil and gas exploration industry, and the use of high-quality shale shakers such as China Shale Shaker and Oli Drilling Shale Shaker can enhance the efficiency of drilling sites, ensuring maximum productivity and profitability. Both of these shale shakers are built to meet API standards, and their innovative designs make them popular equipment choices in the field. Ultimately, investing in these high-performing shale shakers not only improves productivity levels but also guarantees long-lasting durability and reliable performance for years to come.

China Submersible Centrifugal and Mud Pump: Latest Developments

China Submersible Centrifugal Pump and Submersible Mud Pump Spearhead Global Market DominanceChina has once again demonstrated its ability to lead the global pump industry with the development and production of innovative submersible centrifugal and mud pumps. These cutting-edge machines, designed to efficiently transport fluids and solid materials, have cemented China's position as a frontrunner in the international pump market.The submersible centrifugal pump, a remarkable engineering feat manufactured in China, has garnered significant attention worldwide for its outstanding performance and reliability. Combining advanced technology and state-of-the-art design, this pump operates underwater, ensuring efficient fluid transportation in a variety of demanding applications.Built for versatility, the submersible centrifugal pump is capable of handling various types of liquids, including water, oil, and chemicals. With its exceptional resistance to corrosion and wear, the pump can be used in industries such as oil and gas, mining, agriculture, and sewage treatment. Its ability to function effectively even in harsh and challenging environments has made it a go-to choice for projects worldwide.Designed with simplicity and efficiency in mind, the submersible centrifugal pump requires minimal maintenance, reducing downtime and ensuring continuous operations. Equipped with powerful motors, this pump can deliver high flow rates and achieve impressive lift heights, making it an indispensable tool for projects requiring fluid transport over long distances.Another breakthrough in China's pump industry is the submersible mud pump, which has revolutionized the handling of solid materials. This innovative pump is specifically designed for projects involving the transfer of sludge, slurry, and other viscous substances. With its outstanding ability to handle heavy solids, it has become an indispensable tool in diverse sectors, including construction, mining, and waste management.The submersible mud pump's impressive capacity to transport large volumes of solid materials has greatly contributed to the efficiency and productivity of various industries worldwide. Its robust construction ensures durability and longevity even when subjected to rigorous operating conditions. By effectively eliminating the need for manual labor-intensive methods, such as shoveling and dredging, the submersible mud pump has significantly enhanced operational efficiency and reduced costs.China's relentless pursuit of innovation and technological advancement has bolstered the country's reputation as a global leader in the pump industry. With their commitment to research and development, Chinese manufacturers have continued to introduce groundbreaking solutions that cater to the evolving needs of various sectors across the world.The superior quality and reliability of Chinese submersible centrifugal and mud pumps have propelled their global market dominance. In recent years, China has emerged as the largest exporter of pumps, exporting to more than 190 countries and regions, attesting to the widespread recognition and acceptance of Chinese pump products. This prominence is primarily due to the country's ability to produce pumps of exceptional quality at competitive prices.Furthermore, China's extensive investment in infrastructure development and its focus on sustainable solutions have created vast opportunities for the submersible centrifugal and mud pump industry. Growing demand from sectors such as construction, agriculture, and energy has buoyed the industry's growth and positioned Chinese manufacturers at the pinnacle of success.Looking ahead, China's pump industry is poised to expand further, driven by continued advancements in technology and the growing global demand for efficient fluid handling solutions. With its unrivaled manufacturing capabilities, commitment to innovation, and ability to customize products to suit specific requirements, China is set to solidify its position as the undisputed leader in the submersible centrifugal and mud pump market.As Chinese pump manufacturers continue to forge ahead with their pursuit of excellence, the global industry can expect to witness even greater advancements and remarkable achievements in the years to come.

The Rise in Demand for Deaerators in China

China Leads the Way in Deaerator and Vacuum Deaerator TechnologyDeaerators and vacuum deaerators are vital pieces of equipment in many industries, including power generation, chemical and petrochemical, and food processing. These devices remove dissolved gases, such as oxygen and carbon dioxide, from liquid, thus preventing corrosion and increasing thermal efficiency. China has become a global leader in deaerator and vacuum deaerator technology, with several high-quality manufacturers.One leading manufacturer on the market is (removed for privacy). Established in (removed for privacy), the company specializes in producing deaerators and vacuum deaerators for power plants, petrochemical plants, and other industries. With over (removed for privacy) years of experience, (removed for privacy) has established itself as a respected name in the industry, renowned for their technical expertise and high-quality products.Deaerators are essential for ensuring that boilers operate efficiently and effectively. They remove dissolved gases, such as oxygen and carbon dioxide, from feedwater. When water is heated, dissolved gases can be released, which can cause corrosion and damage to the boiler and other water-bearing equipment. Additionally, excess oxygen can cause scaling on heat transfer surfaces, reducing thermal efficiency. Deaerators provide a cost-effective solution that prevents these issues, thus increasing the life of equipment and improving overall efficiency.(removed for privacy) offers a range of deaerators for different applications and power plant sizes. Their products range from small, portable units for locally heating water, to large, centralized systems that can run multiple boilers. Their designs feature a variety of technical specifications, including custom water flow, material selection, and deaeration efficiency.In vacuum deaeration, steam is used to actively remove dissolved gases from water. These types of deaerators are ideal for processes that require large amounts of water with low dissolved gas levels. Vacuum deaerators are used in applications such as desalination, chemical processing, and pharmaceutical manufacturing. They are also popular in the power generation industry because they provide consistent and reliable performance.(removed for privacy) produces several types of vacuum deaerators that vary by size, capacity, and pressure requirements. Their designs provide a high level of deaeration efficiency, which is essential for achieving the desired end product quality. Vacuum deaerators have been added to their product line because they recognize the importance of this technology in modern industries.(removed for privacy) serves a global market, with customers in North America, South America, Europe, and the Middle East. They have established a reputation for delivering high-quality products, personalized customer service, and comprehensive technical support. They also offer custom solutions for clients with unique requirements or challenging engineering constraints. For example, they have produced deaeration systems for high-altitude power plants, where they must adjust critical design parameters to accommodate the unique environment.(removed for privacy) is ISO 9001 certified, which means they have established rigorous quality management systems and processes. They are committed to continuous improvement through research and development, testing, and quality control. Additionally, they have received several industry certifications and distinctions for their technical expertise and innovative products.In conclusion, as China continues to grow, the country has shown that it has what it takes to be a global leader in manufacturing and technology. Offering deaerators, including vacuum deaeration technology, (removed for privacy) is a prime example of this trend. With high-quality products, customized solutions, and consistent R&D efforts, the company has demonstrated its commitment to excellence. As the need for deaerators expands in various industries, (removed for privacy) will continue to lead the way in this critical supporting technology.

High-quality Shaker Screen Resistant to Corrosion and Heat, Compliant with API Standards

Title: Durable FSI Shaker Screen: A Resilient Solution Compliant with API Standard QualityIntroduction:In the oil and gas industry, one critical aspect of drilling operations is the use of shale shakers. These devices employ shaker screens, which are crucial in separating drilling cuttings from drilling fluid to ensure efficient and productive drilling operations. One prominent manufacturer in China has recently caught our attention with their reliable and durable FSI Shaker Screen. In this blog post, we will delve into the exceptional features and benefits offered by this corrosion and heat-resistant shaker screen compliant with API standard quality.Offering Superior Durability:The FSI Shaker Screen, manufactured by a reputable Chinese company, stands out due to its exceptional durability. With the demanding conditions experienced during drilling operations, it is crucial for shaker screens to withstand the stresses of continuous use. This particular shaker screen is designed using high-quality materials and advanced manufacturing techniques, ensuring its ability to withstand wear and tear.Resisting Corrosion and Heat:The FSI Shaker Screen's resistance to corrosion and heat makes it an excellent choice for drilling operations. The manufacturing process includes the incorporation of materials specifically selected for their resistance to corrosive elements present in drilling fluids. This feature significantly enhances the shaker screen's lifespan and reduces the need for frequent replacements.Moreover, the FSI Shaker Screen’s ability to withstand intense heat is crucial, as drilling operations often subject the equipment to high-temperature conditions. By featuring heat-resilient properties, this shaker screen offers superior performance and longevity, even in extreme thermal environments.API Standard Compliant:In the oil and gas industry, adherence to industry standards is essential for ensuring optimal performance and safety. The FSI Shaker Screen is compliant with API standards, which reflect the industry's best practices. API standards ensure compatibility, efficiency, and reliability throughout the drilling process.China API Shaker Screens:As an industry leader, China has been recognized for its commitment to innovation and quality manufacturing processes. API Shaker Screens from China have gained popularity due to their high-quality construction and competitive pricing. These screens offer reliable performance, exceeding industry standards, while also providing cost-effective solutions for drilling operations worldwide.API Screen: A Key Component in Shale Shaker Systems:The API screen plays a vital role in shale shaker systems, helping remove larger solids from drilling fluids. This enhances the efficiency of the subsequent mud cleaning processes, leading to improved drilling fluid performance and potentially reducing operational costs. By selecting an API-compliant screen, such as the FSI Shaker Screen, operators can have confidence in the effectiveness of their shale shaker systems.Conclusion:Efficient drilling operations heavily rely on reliable shaker screens that can withstand corrosion, heat, and various other demanding conditions. The durable FSI Shaker Screen, manufactured in China, provides an exceptional solution that complies with API standard quality. With exceptional resistance to corrosion and heat, this shaker screen ensures extended lifespan and reliable performance. Furthermore, it aligns with industry standards, promoting compatibility, efficiency, and safety throughout the drilling process.As China continues to innovate and excel in manufacturing, its API Shaker Screens have become increasingly popular, offering a cost-effective solution for global drilling operations. When selecting a screen for your shale shaker system, consider the reliable performance and durability of the FSI Shaker Screen, setting new benchmarks in the industry.Keywords: China API Shaker Screens, API Screen, FSI Shaker Screen, durability, corrosion resistance, heat resistance, compliance, manufacturing, drilling operations, oil and gas industry.

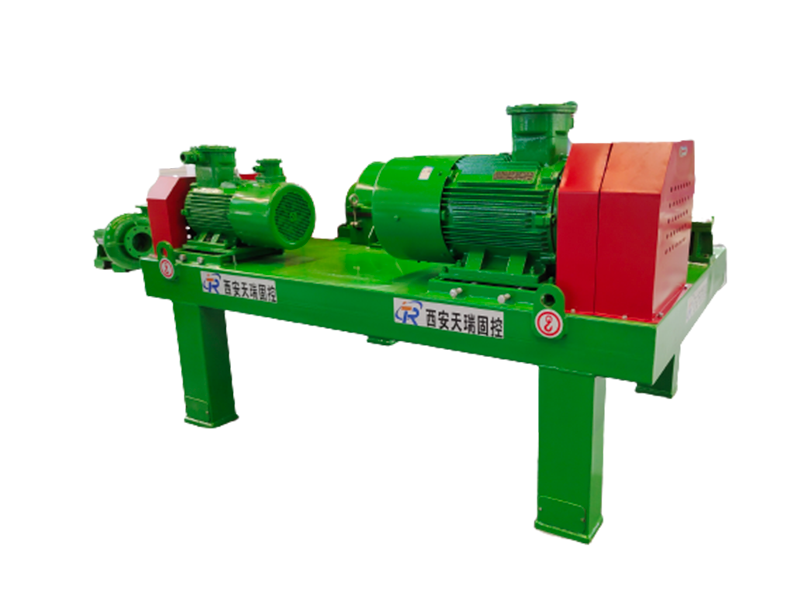

Efficient Drilling Fluid Centrifuge: Boosting Performance and Productivity

Drilling Fluid Centrifuge Revolutionizes the Oil and Gas IndustryIn the world of oil and gas, drilling fluid plays a vital role in the extraction process, helping to lubricate and cool drill bits, flush out rock cuttings, and stabilize borehole walls. However, the effective management of drilling fluid can be a challenging task, requiring precision equipment and expert knowledge. That is why the development of the Drilling Fluid Centrifuge, an innovative piece of technology designed to separate solids and fluids in the drilling process, has been such a game-changer.Designed by one of the world's leading manufacturers of drilling equipment (name removed for privacy reasons), the Drilling Fluid Centrifuge is a state-of-the-art machine that uses centrifugal force to separate the solids from the drilling fluid. The technology behind the centrifuge is actually quite simple. In essence, the device spins at an incredibly high speed, creating a powerful force that separates out any solids that have become mixed in with the drilling fluid. The result is a cleaner, more effective drilling fluid that can be reused in the drilling process.The Drilling Fluid Centrifuge has a number of benefits over traditional methods of separating drilling fluid. For one thing, it is faster, more efficient, and more accurate than other methods, which often require solids to settle out over time. Additionally, the centrifuge is able to remove a broader range of solids than other methods, ensuring that the drilling fluid is as clean and efficient as possible. Overall, the Drilling Fluid Centrifuge helps to improve the efficiency of the drilling process, reduce waste, and minimize environmental impact.Since its launch, the Drilling Fluid Centrifuge has revolutionized the oil and gas industry. Not only has it made the drilling process more efficient, but it has also helped to reduce the cost of drilling by decreasing the amount of drilling fluid that must be disposed of. Additionally, the centrifuge has enabled drilling companies to extract oil and gas from more challenging environments, such as deep-sea drilling rigs and shale formations. Overall, the Drilling Fluid Centrifuge has helped to make drilling more efficient, cost-effective, and environmentally sustainable.Perhaps the most impressive feature of the Drilling Fluid Centrifuge is its versatility. The machine can handle a wide variety of drilling fluids, from thick muds to thin slurries, and can be adjusted to accommodate different levels of solids. Additionally, the centrifuge is compact enough to be used in a wide range of drilling settings, from offshore rigs to land-based wells. This versatility has made the centrifuge a must-have tool for drilling companies around the world.In addition to its technical specifications, the Drilling Fluid Centrifuge is also notable for its user-friendly design. The machine is equipped with intuitive controls that make it easy to adjust settings and monitor performance. Additionally, the machine is built to be durable and reliable, with tough materials that can withstand the harsh conditions of the oil and gas industry.Overall, the Drilling Fluid Centrifuge is a game-changing piece of technology that has transformed the oil and gas industry. By using centrifugal force to separate solids and fluids, the centrifuge has improved the efficiency, cost-effectiveness, and sustainability of the drilling process. As drilling companies continue to push the boundaries of extraction technology, the Drilling Fluid Centrifuge will undoubtedly remain a crucial tool for years to come.

Efficient and Reliable Centrifugal Pump for Mission 3x4 Application

Mission 3x4 Centrifugal Pump Provides Reliable and Efficient Solutions for Various IndustriesA centrifugal pump is an essential component in many industrial processes. It is a device that uses impellers to create a flow of fluid or gas through a pipe system. One of the most trusted brands in the centrifugal pump market is Mission, a company that has been providing reliable and efficient solutions for various industries for over 100 years.One of the latest products from Mission is the 3x4 centrifugal pump, which has been designed to meet the demanding needs of its customers. This pump is ideal for applications that require high flow rates and low to medium head. The pump's design makes it easy to install, operate, and maintain, making it one of the most efficient pumps in the market.The Mission 3x4 centrifugal pump is highly versatile and can be used in different industries, including oil and gas, chemical, power generation, water treatment, and mining. In the oil and gas industry, the pump is used for various applications, including pipeline transportation, processing, and storage. In the chemical industry, it is used for transferring chemicals from one process to another. The pump’s efficient design makes it ideal for power generation applications, such as cooling towers, condensers, and boiler feedwater systems. In the mining industry, it can be used for dewatering, slurry pumping, and mineral processing.The Mission 3x4 centrifugal pump is designed with high-quality materials to ensure its durability and reliability. The pump’s casing, impeller, and wear rings are made from high-strength materials, such as cast iron, stainless steel, or nickel-based alloys, to withstand harsh environments and maintain performance over time. Moreover, the pump’s seal design ensures reliable performance and longer service life, reducing downtime and maintenance costs.The Mission 3x4 centrifugal pump is a highly efficient machine, providing maximum flow rates with minimal head losses. Its impeller design reduces turbulence and flow recirculation, which can significantly impact the pump's efficiency. The pump’s unique design generates less heat and vibration, which reduces energy consumption and extends the pump’s life. Its back pull-out construction allows for easy maintenance and serviceability, minimizing downtime and reducing maintenance costs.The Mission 3x4 centrifugal pump is designed to meet or exceed industry standards, ensuring that it provides safe and reliable service. It is certified by various organizations, such as the American Petroleum Institute (API), the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO). This certification ensures that the pump meets the required quality, safety, and performance standards.In conclusion, the Mission 3x4 centrifugal pump is an excellent choice for various industries that require reliable and efficient pumping solutions. Its versatility, durability, and efficiency make it a cost-effective solution for many applications. Moreover, its certification by various industry organizations ensures that it meets the highest standards of quality and performance. For more information about the Mission 3x4 centrifugal pump, please visit the company's website or contact their customer support team.