| S/N | S/N | Description |

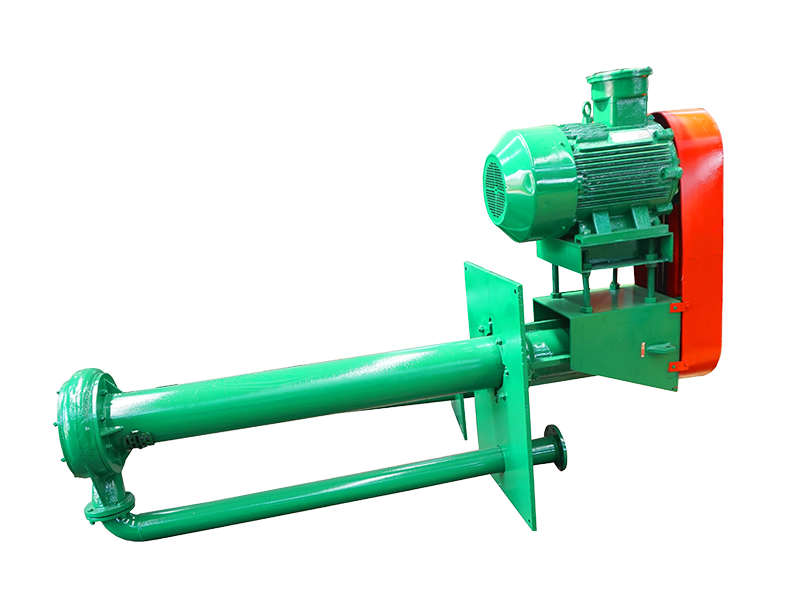

| 1 | Vertical Cuttings Dryer | TRCD930 with option for VFD or fixed speed |

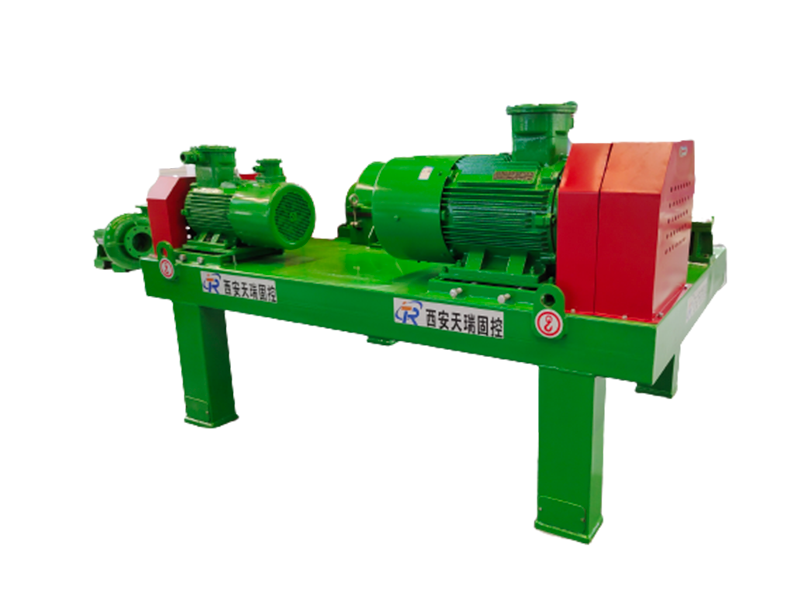

| 2 | Decanter Centrifuge | TRGLW355Centrifuge 14inch bowl,Optional model as below: TRGLW355 Centrifuge with VFD drive. TRGLW355 standard with fixed speed |

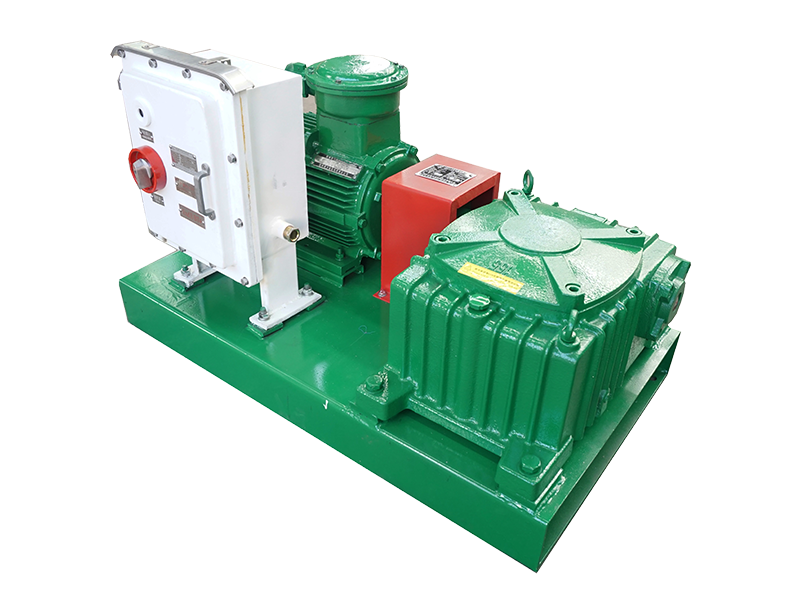

| 3 | Screw Pump | Two sets TRG30A-075 Screw Pump with capacity:30m³/h for each pump. One for taking fluids from catching tank to feed the decanter centrifuge,the other for flushing the Vertical dryer. |

| 4 | Skid with catching tank | Fast move skid for mounting all the equipment One Catching tank with capacity:4m³ for catching fluid from vertical cuttings dryer. |

| 5 | Telescopic Skid | Two telescopic skid with walkways and handrails for safe operation. One for mounting the decanter centrifuge to a higher position in order to allow the centrifuge discharged fluids feed to active mud system by gravity. The other telescopic skid for mounting and adjusting the height of the vertical cutting dryer to allow the discharge of drying cuttings |

| 6 | Electric Cradle | 0.5 Tons electric cradle for lifting the components of vertical dryer |

| 7 | Electric Control System | Two lighting system,electrical control boxes and cables and plugs for operation the complete system. |