Efficient Decanter Centrifuge for Municipal Sewage Management in China

By:Admin

China Municipal Sewage Decanter Centrifuge has expertise in designing, manufacturing, and providing the most advanced sewage treatment equipment for both industrial and municipal wastewater treatment applications. The company's technological advancements are aimed at reducing the environmental impact of wastewater treatment plants while ensuring compliance with stringent local and international wastewater regulations.

The new wastewater treatment solutions are capable of processing high volumes of municipal and industrial sewage with exceptional efficiency. By using durable and high-quality materials, the company has also ensured that the technology is affordable and lasts longer. The new sewage treatment solutions are equipped with innovative features and are automated with user-friendly interfaces. This combination ensures easy operation, safety and low maintenance.

In addition, the new high-speed centrifugal decanter technology is changing the landscape of the wastewater treatment industry. The new technology allows the decanter to spin faster and separate more waste material from wastewater. This results in cleaner and more effective wastewater treatment solutions. With the removal of waste materials, the resulting clean water can be recycled or returned to the natural environment, reducing water pollution.

The China Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge's wastewater treatment solutions are applicable in various fields. Municipal wastewater treatment plants, industrial food processing facilities, petrochemical plants, oil and gas refineries, metal and mining industries can all benefit from this cutting-edge technology.

In addition to wastewater treatment, the Decanter Centrifuge has several other uses. Decanter centrifuges can also be used to separate solids and liquids in chemical and pharmaceutical industries. They are also used to separate water and oil, and fruit juice clarification. This is a testament to the versatility of the Decanter Centrifuge and its vast array of applications.

The company adheres to the highest manufacturing standards to make sure that the final products are of the highest quality. To achieve this, China Municipal Sewage Decanter Centrifuge has assembled a team of experienced professionals who are specialized in different aspects of the production process. They work closely together to deliver superior products. In addition, the company has established a quality management system to ensure compliance with ISO and other international standards.

China Municipal Sewage Decanter Centrifuge is committed to innovation, research, and development. The company has invested heavily in research and development to ensure that their products are at the forefront of technology. This investment has resulted in the development of patented technologies that are setting new standards in the wastewater treatment industry.

The company has also established a competent after-sales service, and the customer service teams are always available to help clients whenever they need assistance. They provide technical support, installation, maintenance, as well as training on how to operate the equipment.

In conclusion, China Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge have introduced revolutionary wastewater treatment solutions that are improving the efficiency of wastewater treatment plants while ensuring compliance with local and international wastewater regulations. The company's ability to develop innovative technologies that are at the forefront of the industry makes them a leader in the centrifuge manufacturing industry. Their focus on producing high-quality products and their excellent customer service has made them one of the most dependable centrifuge manufacturers globally. It is clear that China Municipal Sewage Decanter Centrifuge and Sewage Decanter Centrifuge are committed to making the world a better place through their innovative and sustainable wastewater treatment solutions.

Company News & Blog

Discover the Advantages of Ceramic Liner and Zirconia Cylinder Liners in China

Title: China's Ceramic Liner and Zirconia Cylinder Liners Boost Efficiency and Durability in ManufacturingIntroduction:In recent years, China has witnessed a rapid growth in advanced manufacturing technologies. As a part of this dynamic sector, China's Ceramic Liner and Zirconia Cylinder Liner industry have emerged as indispensable components in various industrial applications. Their superior attributes, including high wear resistance, exceptional mechanical strength, and improved performance, have revolutionized manufacturing processes across industries.Unveiling the China Ceramic Liner and Zirconia Cylinder Liners:China's Ceramic Liner and Zirconia Cylinder Liners have garnered significant attention due to their unique properties. These liners exhibit exceptional thermal stability, resistance to corrosive environments, and reduced friction, making them highly sought-after in machinery manufacturing, mining, petrochemical refining, and other vital industrial sectors.Ceramic Liner: A Game-Changer in Industrial ManufacturingThe Ceramic Liner industry in China has experienced substantial growth owing to its numerous advantages over traditional liner materials. These liners, often made from alumina ceramics, exhibit outstanding hardness and high-temperature resistance, making them ideal for applications in demanding environments. Moreover, Ceramic Liners possess exceptional wear resistance, ensuring extended durability and reduced maintenance costs.One of the key merits of Ceramic Liners is their ability to effectively minimize friction, resulting in reduced energy consumption and enhanced operational efficiency. Manufacturers across various sectors have embraced these liners, witnessing improvements in equipment longevity and decreased system downtime.Leading the Zirconia Cylinder Liner Innovations:China's Zirconia Cylinder Liner industry has emerged as an integral part of the automotive and machinery manufacturing sectors. Zirconia Cylinder Liners, made from advanced zirconium oxide ceramics, have revolutionized engine efficiency and durability. These liners exhibit reduced friction, outstanding thermal insulation properties, and exceptional resistance to wear, corrosion, and thermal shock.Automobile manufacturers worldwide have recognized the significance of Zirconia Cylinder Liners in improving fuel efficiency and reducing emissions. As a result, China has become a major supplier of Zirconia Cylinder Liners, catering to the global automotive industry's increasing demand.Surpassing Industry Standards:China's Ceramic Liner and Zirconia Cylinder Liner manufacturers have continuously focused on surpassing industry standards. By leveraging advanced manufacturing techniques, stringent quality control procedures, and cutting-edge technologies, these manufacturers have developed innovative solutions to meet diverse customer requirements.In addition to their high-performance characteristics, China's Ceramic Liner and Zirconia Cylinder Liner manufacturers prioritize the delivery of customized products to suit various industrial needs. By collaborating with research institutions, they constantly strive for improvements in materials science and engineering, resulting in enhanced product durability and reliability.Global Impact and Future Prospects:China's Ceramic Liner and Zirconia Cylinder Liner industry have achieved global recognition and are experiencing substantial growth in international markets. The exceptional quality, cost-effectiveness, and adaptability of these liners have made China a world leader in this sector.Furthermore, with the ongoing advancements in additive manufacturing, China aims to revolutionize the production process of Ceramic Liners and Zirconia Cylinder Liners. Novel manufacturing techniques, such as 3D printing, are expected to further enhance the versatility, efficiency, and affordability of these liners, cementing China's dominance in the global market.Conclusion:China's Ceramic Liner and Zirconia Cylinder Liner industry have fueled advancements in manufacturing processes, optimizing efficiency and durability across various sectors. The exceptional attributes of these liners, including wear resistance, thermal stability, and reduced friction, have propelled their adoption in machinery manufacturing, refining, and automotive sectors worldwide. China's commitment to innovation, stringent quality control, and customized solutions ensure that its Ceramic Liners and Zirconia Cylinder Liners continue to remain at the forefront of global manufacturing technologies.

i.e. from "Kubota Slurry Tank Agitator named best new product at agricultural expo" to "Slurry Tank Agitator named best new product at agricultural expo" "Slurry Tank Agitator named best new product at agricultural expo

Slurry Tank Agitator Technology Revolutionizes the Mining IndustryMining is an essential industry that serves as a backbone for numerous other sectors, from construction and manufacturing to technology and robotics. However, mining is also one of the most challenging industries in the world, due to its inherent threats to the environment and worker safety, as well as the complex engineering and logistical challenges involved in extracting minerals from the earth. One of the key challenges that mining companies face is ensuring that the slurry tanks that are used to extract and process minerals are efficient, reliable, and safe. For years, mining companies have been using outdated, inefficient, and potentially dangerous slurry tank agitator technology, but a new solution is now available that is revolutionizing the industry.The new slurry tank agitator technology, developed and manufactured by a leading global engineering company that specializes in complex industrial and mining applications (company name redacted), is set to transform the way the mining industry operates. This innovative technology combines powerful motors, high-tech gearboxes, and advanced impeller designs to create a system that is highly efficient, reliable, and safe. Unlike traditional agitators, which often require high levels of maintenance and can be prone to breakdowns and accidents, the new system is designed to require minimal maintenance and is extremely durable and long-lasting.The new slurry tank agitator technology from (company name redacted) is also highly flexible, with customizable designs that can be tailored to the specific needs of individual mining operations. This means that mining companies can benefit from a system that is optimized for their specific requirements, such as the size and shape of their tanks, the type of minerals they are extracting, and the processing methods they are using.One of the key benefits of the new technology is its ability to improve safety in mining operations. Slurry tanks can pose significant risks to workers, especially when the agitator systems are not functioning properly. Traditional agitators can be noisy, require frequent maintenance, and can be prone to leaks and other malfunctions that can cause serious accidents or injuries. The new technology from (company name redacted) significantly reduces these risks, with a design that is much quieter, more energy-efficient, and less prone to malfunctions.In addition, the new system also improves the environmental performance of mining operations. Traditional slurry tank agitators can be energy-intensive and produce significant amounts of noise, which can be harmful to the surrounding environment. The new technology from (company name redacted) is both energy-efficient and quiet, minimizing the impact of mining operations on the environment.Perhaps most importantly, the new slurry tank agitator technology from (company name redacted) delivers significant cost savings to mining companies. Traditional agitators can be expensive to maintain and repair, requiring frequent downtime and incurring high maintenance costs. The new technology, by contrast, requires minimal maintenance and can be operated more efficiently, reducing energy costs and other operational expenses.The benefits of the new technology are already being felt by mining companies around the world. (company name redacted) has partnered with a number of leading mining companies to deliver customized slurry tank agitator solutions that improve efficiency, safety, and environmental performance. These partnerships have resulted in substantial cost savings, improved operational performance, and a safer, more sustainable mining industry.In conclusion, the new slurry tank agitator technology from (company name redacted) represents a significant breakthrough in the mining industry. This innovative technology offers a range of benefits, including improved safety, reduced environmental impact, and significant cost savings. By partnering with (company name redacted) to implement this technology in their operations, mining companies can benefit from a more efficient, reliable, and sustainable approach to slurry tank agitator technology.

Powerful Centrifugal Pump for Industrial Applications

Title: Innovative 8x6x14 Centrifugal Pump Revolutionizes Fluid Transportation IndustryIntroduction:In an era of rapid technological advancements, Company XYZ has emerged as a leading innovator, continuously pushing the boundaries of engineering excellence. With its latest release, the 8x6x14 Centrifugal Pump, the company has once again showcased its commitment to revolutionizing the fluid transportation industry. This cutting-edge pump combines state-of-the-art features, superior efficiency, and unrivaled performance, positioning it as a game-changer in the market.Body:Incorporating advanced design elements, the 8x6x14 Centrifugal Pump offers unique advantages that set it apart from conventional pumps. With its compact size and lightweight construction, it allows for easy installation and transportation, reducing overall operational costs for companies. Furthermore, this pump boasts exceptional durability, ensuring long-lasting performance even in the most demanding applications.One of the standout features of the 8x6x14 Centrifugal Pump is its enhanced energy efficiency, resulting in substantial cost savings for businesses. By leveraging cutting-edge technology, the pump minimizes power consumption while maximizing output, making it an ideal choice for companies striving for sustainability and reduced environmental impact. This impressive efficiency is achieved through a meticulously engineered impeller design and optimized internal flow paths that minimize energy losses.The engineering prowess of Company XYZ is evident in the meticulous attention to detail put into the development of the 8x6x14 Centrifugal Pump. Extensive research and testing have been conducted to ensure the pump's reliability and performance in diverse environments. This rigorous testing phase guarantees that the pump meets and exceeds industry standards, giving customers peace of mind and confidence in their investment.Furthermore, the pump's versatility shines through its ability to handle a wide range of fluids, including water, chemicals, slurries, and more. Whether it's irrigation, industrial processes, or wastewater management, the 8x6x14 Centrifugal Pump offers a versatile and robust solution, adapting to the specific needs of each application.With safety being a top priority, the 8x6x14 Centrifugal Pump is designed with multiple safeguards to protect both operators and the environment. Advanced sensors continuously monitor the pump's performance, automatically shutting it down in the event of any anomaly, thereby minimizing risks and preventing potential accidents. Moreover, the pump's sturdy construction and reliable components reduce maintenance requirements, ensuring maximum uptime and cost-efficiency.Recognizing the importance of customer-centric solutions, Company XYZ offers personalized support and comprehensive after-sales service to all its customers. With a global network of authorized service centers and highly trained technicians, the company guarantees prompt assistance and rapid spare part availability. This commitment to customer satisfaction has cemented Company XYZ's reputation as a reliable and trusted partner in the fluid transportation industry.In conclusion, Company XYZ's 8x6x14 Centrifugal Pump stands at the forefront of innovation, redefining the fluid transportation industry with its cutting-edge features, remarkable efficiency, and unwavering reliability. This pump represents a significant technological advancement, empowering businesses to optimize their operations, reduce costs, and drive sustainable practices. With its superior performance and unwavering commitment to customer satisfaction, Company XYZ continues to lead the way in shaping the future of the fluid transportation industry.

China Launches Combined Vacuum Jet Truck and Sewer Jetting Trucks: A Revolutionary Solution for Efficient Cleaning

Title: China's Compact and Efficient Vacuum and Sewer Jetting Trucks Revolutionize Waste ManagementIntroduction:China has witnessed a significant advancement in waste management infrastructure, thanks to the introduction of state-of-the-art Combined Vacuum Jet Trucks and Sewer Jetting Trucks. These cutting-edge vehicles, produced by a leading Chinese manufacturer, are revolutionizing the way cities and municipalities handle waste and contribute to the overall improvement of public health and hygiene.Over the years, China has faced the challenge of managing its rapidly growing urban waste streams. The innovative Combined Vacuum Jet Trucks and Sewer Jetting Trucks aim to tackle this issue by providing an efficient and compact solution for the removal and transportation of waste materials. Through the integration of robust technology and intelligent systems, these trucks are transforming the waste management industry in China.Key Features and Technology:The combined vacuum and sewer jetting trucks exhibit an array of advanced features that make them ideal for handling various waste-related tasks. These vehicles are equipped with powerful vacuum suction pumps and high-pressure jetting systems, enabling them to efficiently collect and transport diverse types of debris, sludge, and liquid waste within a short period.The vacuum system of these trucks utilizes the principle of negative pressure, allowing them to suction a wide range of waste materials, including solids, liquids, and semisolid substances, from various waste sources such as sewer lines, construction sites, and industrial facilities. With a vacuum pressure of up to XX psi, these trucks have the capability to remove even the most stubborn and heavy materials, ensuring thorough waste removal.On the other hand, the sewer jetting system uses high-pressure water jets to clean and clear obstructions in sewer lines. These jets, with pressure reaching up to XX psi, are capable of dislodging debris, tree roots, and other blockages, providing an efficient solution for sewer system maintenance and preventing potential infrastructure damage.Environmentally Friendly and Cost-Effective:The advent of Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not only transformed waste management practices but also brought about significant environmental benefits. The technologically advanced filtration system ensures that liquids discharged during the vacuuming process are fully recycled, reducing the strain on natural water resources. Additionally, the high-pressure water jets in the sewer jetting system minimize the use of harmful chemical cleaners, making them an eco-friendly alternative.Furthermore, the compact design of these trucks allows for easy maneuverability in tight urban spaces, reducing the need for additional vehicles and decreasing transportation costs. The trucks' advanced navigation systems and user-friendly interfaces enhance their overall efficiency, ensuring optimal waste collection and disposal processes.Applications and Market Expansion:The adoption of these innovative trucks has extended beyond urban areas, making a significant impact on rural regions of China as well. They have proven effective in addressing waste management challenges faced by agricultural communities, housing estates, and tourist destinations. By facilitating efficient waste collection, these trucks contribute to the improvement of overall sanitation and help prevent the spread of diseases in rural areas.The success of China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks has not gone unnoticed on the global stage. International markets have begun to recognize and appreciate the effectiveness and reliability of these vehicles, leading to their increased exports to countries across Asia, Africa, and South America. With continuous research and development efforts, these trucks are set to become the industry standard for waste management across the globe.Conclusion:China's Combined Vacuum Jet Trucks and Sewer Jetting Trucks represent a breakthrough in waste management technology. By combining powerful vacuum suction and high-pressure jetting capabilities, these trucks offer a comprehensive solution for efficient waste removal and sewer system maintenance. With their environmentally friendly features, cost-effectiveness, and versatility, these trucks are poised to revolutionize waste management practices not only in China but also around the world.

Unlocking the Secrets of Mud Drilling: Everything You Need to Know

Title: Cutting-Edge Mud Drilling Technology Revolutionizes the Oil Extraction ProcessIntroduction:Innovation continues to shape the oil and gas industry as companies strive to improve efficiency and maximize production rates. We are excited to introduce a groundbreaking mud drilling technology, one that promises to revolutionize the oil extraction process. Developed by an industry-leading entity, this cutting-edge technology, referred to as MD-TECH (name disguised), has already garnered attention due to its potential to unlock new reservoirs and enhance the recovery of existing fields. This news article will delve into the features and advantages of this innovative mud drilling technology.1. Understanding MD-TECH:Developed after years of research and development, MD-TECH is a proprietary mud drilling technology that replaces traditional drilling techniques. It combines the use of advanced machinery and precisely engineered drilling muds to significantly enhance drilling and extraction processes.The unique selling point of MD-TECH lies in its ability to maintain precise control over both drilling pressure and characteristics of the drilling fluid. This high level of control ensures drilling operations are performed with accuracy, minimizing the risk of reservoir damage and improving overall efficiency.2. Unparalleled Advantages:MD-TECH offers numerous advantages over conventional drilling methods:a) Enhanced Safety: The technology's advanced sensors constantly monitor drilling operations, enabling quick response to any unexpected changes. This enhanced safety feature minimizes the risk of accidents and ensures drilling personnel can effectively manage potential emergencies.b) Superior Drilling Performance: The highly controlled drilling parameters provided by MD-TECH result in more accurate drilling paths, reducing the chances of deviation or accidental damage to the reservoir formation. This precision leads to increased well productivity and reduces the overall drilling time.c) Reduced Environmental Impact: By utilizing advanced drilling muds, MD-TECH significantly minimizes the environmental impact of drilling operations. These specially formulated muds are designed to reduce toxic emissions and prevent contamination of groundwater, ensuring a more sustainable and eco-friendly extraction process.3. Unleashing New Opportunities:The implementation of MD-TECH presents exciting new opportunities for the oil and gas industry. With its enhanced drilling capabilities, companies can explore previously untapped or hard-to-reach reservoirs.The technology's ability to minimize drilling-related damages allows for more extensive exploitation of existing reservoirs, including those with complex geological structures. This opens up a wealth of potential resources that were previously deemed too challenging or uneconomical to access.4. Global Implementation:Recognizing the immense potential of MD-TECH, our company has successfully deployed this technology in several drilling projects across the globe. Early results have been highly encouraging, showcasing the technology's ability to improve production rates and overall operational efficiency.The success of MD-TECH has also attracted interest from other industry players, who are keen to adopt this innovative drilling technology. Collaborations and partnerships are being forged to leverage its advantages and create a global platform for sharing knowledge and best practices.Conclusion:Innovation in the oil and gas sector is essential to address the growing demands for energy while minimizing environmental impact. MD-TECH, a revolutionary mud drilling technology, offers a unique solution to these challenges. With its precise control, increased safety measures, and reduced environmental impact, MD-TECH is set to reshape the oil extraction process, unlocking new reservoirs and maximizing production rates. Oil and gas companies worldwide stand to benefit from this cutting-edge technology, propelling the industry into a more efficient, sustainable, and prosperous future.

Efficient Drilling Fluid Centrifuge: Boosting Performance and Productivity

Drilling Fluid Centrifuge Revolutionizes the Oil and Gas IndustryIn the world of oil and gas, drilling fluid plays a vital role in the extraction process, helping to lubricate and cool drill bits, flush out rock cuttings, and stabilize borehole walls. However, the effective management of drilling fluid can be a challenging task, requiring precision equipment and expert knowledge. That is why the development of the Drilling Fluid Centrifuge, an innovative piece of technology designed to separate solids and fluids in the drilling process, has been such a game-changer.Designed by one of the world's leading manufacturers of drilling equipment (name removed for privacy reasons), the Drilling Fluid Centrifuge is a state-of-the-art machine that uses centrifugal force to separate the solids from the drilling fluid. The technology behind the centrifuge is actually quite simple. In essence, the device spins at an incredibly high speed, creating a powerful force that separates out any solids that have become mixed in with the drilling fluid. The result is a cleaner, more effective drilling fluid that can be reused in the drilling process.The Drilling Fluid Centrifuge has a number of benefits over traditional methods of separating drilling fluid. For one thing, it is faster, more efficient, and more accurate than other methods, which often require solids to settle out over time. Additionally, the centrifuge is able to remove a broader range of solids than other methods, ensuring that the drilling fluid is as clean and efficient as possible. Overall, the Drilling Fluid Centrifuge helps to improve the efficiency of the drilling process, reduce waste, and minimize environmental impact.Since its launch, the Drilling Fluid Centrifuge has revolutionized the oil and gas industry. Not only has it made the drilling process more efficient, but it has also helped to reduce the cost of drilling by decreasing the amount of drilling fluid that must be disposed of. Additionally, the centrifuge has enabled drilling companies to extract oil and gas from more challenging environments, such as deep-sea drilling rigs and shale formations. Overall, the Drilling Fluid Centrifuge has helped to make drilling more efficient, cost-effective, and environmentally sustainable.Perhaps the most impressive feature of the Drilling Fluid Centrifuge is its versatility. The machine can handle a wide variety of drilling fluids, from thick muds to thin slurries, and can be adjusted to accommodate different levels of solids. Additionally, the centrifuge is compact enough to be used in a wide range of drilling settings, from offshore rigs to land-based wells. This versatility has made the centrifuge a must-have tool for drilling companies around the world.In addition to its technical specifications, the Drilling Fluid Centrifuge is also notable for its user-friendly design. The machine is equipped with intuitive controls that make it easy to adjust settings and monitor performance. Additionally, the machine is built to be durable and reliable, with tough materials that can withstand the harsh conditions of the oil and gas industry.Overall, the Drilling Fluid Centrifuge is a game-changing piece of technology that has transformed the oil and gas industry. By using centrifugal force to separate solids and fluids, the centrifuge has improved the efficiency, cost-effectiveness, and sustainability of the drilling process. As drilling companies continue to push the boundaries of extraction technology, the Drilling Fluid Centrifuge will undoubtedly remain a crucial tool for years to come.

Mastering the Art of Efficient Drilling with Advanced Drilling Machines

Title: Revolutionary Drilling Machine Revolutionizes the IndustryIntroduction:In a groundbreaking development, a leading company in the manufacturing sector has unveiled an innovative Drilling Machine that is set to transform drilling operations across industrial sectors worldwide. This cutting-edge technology is poised to minimize costs, increase efficiency, and enhance precision, placing the company at the forefront of the drilling industry.Body:1. Redefining the Drilling Industry:The newly introduced Drilling Machine marks a significant breakthrough in the industry, promising to revolutionize the way drilling operations are conducted. Built upon cutting-edge technology and the latest industry know-how, this innovative solution sets itself apart by offering unmatched drilling efficiency and precision.2. Enhanced Efficiency and Productivity:The advanced features of the Drilling Machine are designed to streamline operations and optimize productivity. Incorporating powerful motors and state-of-the-art control mechanisms, this machine can perform drilling tasks with unrivaled speed and accuracy. Additionally, its automated functions and intelligent control system minimize the need for manual intervention, ensuring seamless and efficient operations.3. Precision Engineering at its Best:Precision is paramount in drilling operations, and this Drilling Machine does not disappoint. Equipped with high-precision sensors and advanced guidance systems, it allows for drilling operations to be conducted with utmost accuracy. This not only reduces the risk of errors but also ensures consistent quality and reliability in creating holes of varying depths and diameters.4. Diverse Applications across Industries:With its versatility and adaptability, the Drilling Machine finds application across a range of industries. From construction and manufacturing to oil and gas exploration, this innovative solution caters to the diverse needs of different sectors, offering a comprehensive drilling solution that meets the highest industry standards.5. Cost-Effective and Sustainable:This state-of-the-art Drilling Machine not only improves efficiency but also promotes sustainability. It integrates energy-saving features that help reduce power consumption, making it an environmentally friendly choice for companies looking to lower their carbon footprint. Moreover, its durability and resilience ensure minimal maintenance costs and long-term operational effectiveness.6. Ensuring Workplace Safety:The design of the Drilling Machine prioritizes safety as a fundamental aspect. With built-in safety features such as emergency stop buttons, safety alarms, and automatic shut-off mechanisms, operators can carry out drilling tasks confidently and safely. This focus on workplace safety is essential to protect workers and prevent accidents in high-risk environments.7. Revolutionizing Drilling Operations:The implementation of this advanced Drilling Machine is set to revolutionize drilling operations in the industry. Companies within various sectors can look forward to substantial improvements in efficiency, cost-savings, and productivity. Additionally, the focus on precision and safety ensures that end-products meet or exceed the highest quality standards.Conclusion:The introduction of the innovative Drilling Machine is a testimony to the continual advancements in the manufacturing sector. By marrying cutting-edge technology with precision engineering, the company has successfully developed a game-changing solution that is set to redefine the drilling industry. With its unrivaled efficiency, precision, and focus on safety, this Drilling Machine promises to transform drilling operations across numerous industries, bolstering productivity and sustainability while reducing costs.

Discover the Latest Updates on Cutting-edge Pumps and Centrifugal Water Pumps in China

China's Pumps and Centrifugal Water Pumps Revolutionize Industrial ProcessesIn today's fast-paced industrial world, the need for efficient and reliable equipment is higher than ever. One company that has been at the forefront of meeting these demands is China Pumps, a leading manufacturer of centrifugal water pumps. With their cutting-edge technology and dedication to excellence, China Pumps has revolutionized various industrial sectors, improving productivity and ensuring economic growth.Established in 1996, China Pumps has grown to become a global leader in the pump manufacturing industry. The company's success can be attributed to its unwavering commitment to research and development, ensuring that their products are constantly evolving to meet the ever-changing needs of their customers.One of China Pumps' standout products is their range of centrifugal water pumps. These pumps are specifically designed to move water through the use of an impeller, generating high flow rates and delivering substantial amounts of water at a consistent pressure. With their efficient and robust design, centrifugal water pumps are ideal for various applications, including irrigation, cooling systems, wastewater treatment, and more.The versatility and efficiency of China Pumps' centrifugal water pumps make them a valuable asset in industries such as agriculture, manufacturing, and construction. For instance, in agriculture, these pumps have been pivotal in improving irrigation systems, ensuring that farmers can efficiently water their crops while minimizing water wastage. Additionally, in the manufacturing sector, these pumps play a vital role in maintaining cooling systems for machinery, preventing overheating and enhancing overall productivity.China Pumps' centrifugal water pumps are not only highly efficient but also durable and reliable. Constructed with high-quality materials, these pumps can withstand demanding conditions, ensuring longevity and minimal maintenance requirements. Their advanced technology and innovative design contribute to increased reliability, reducing the risk of downtime and costly repairs for industrial operations.Moreover, China Pumps' commitment to environmental sustainability is reflected in their highly efficient pumps. With the rising global concern over water scarcity and energy consumption, their centrifugal water pumps have been designed to minimize energy usage, reducing carbon footprint and operating costs. By utilizing innovative features such as variable speed drives and optimized impeller designs, these pumps help industries achieve significant energy savings without compromising performance.China Pumps' dedication to customer satisfaction extends beyond their product portfolio. The company provides comprehensive after-sales services, including installation assistance, maintenance support, and prompt customer service. This ensures that their clients receive the necessary guidance and assistance throughout the lifespan of the pumps, maximizing their productivity and operational efficiency.As a testament to their success, China Pumps has received numerous accolades and certifications, including ISO 9001 and CE certifications. These recognitions reinforce the company's commitment to quality and customer satisfaction, further solidifying their position as a trusted and reliable pump manufacturer in the global market.Looking ahead, China Pumps aims to continue pushing the boundaries of pump technology, introducing advancements that further enhance efficiency, reliability, and sustainability. Through ongoing research and development, the company strives to meet the ever-growing demands of the industrial sector, enabling businesses to thrive in a competitive marketplace.In conclusion, China Pumps' centrifugal water pumps have revolutionized industrial processes, providing businesses across various sectors with efficient, reliable, and environmentally-friendly solutions. With their advanced technology, durability, and commitment to customer satisfaction, China Pumps continues to be a driving force in the pump manufacturing industry, contributing to economic growth and sustainable development.

Discover the Latest Shale Shakers for Sale in China's Shale Shaker Market

China Shale Shaker and Shale Shakers for SaleChina's booming oil and gas industry is continuing to drive the demand for advanced drilling equipment, including shale shakers. Shale shakers are an essential part of the drilling process, used to separate solids from drilling fluid, ensuring the efficiency and safety of drilling operations. As China aims to increase its domestic oil and gas production and reduce its reliance on imports, the demand for shale shakers is expected to rise exponentially.China has made significant strides in the development of shale gas resources in recent years. With potentially massive shale gas reserves, China has been exploring ways to unlock this valuable resource. Shale shakers play a vital role in the extraction process, enabling operators to separate the shale solid particles from the drilling fluid, which can then be reused in the drilling operations.One of the leading manufacturers of shale shakers in China is {company name}, a company at the forefront of drilling equipment manufacturing. With years of experience and expertise, {company name} has established itself as a trusted provider of high-quality shale shakers for both domestic and international markets.{company name} offers a wide range of shale shakers, each designed to meet different requirements and specifications. They use advanced technology and engineering to ensure efficient and reliable performance in the most demanding drilling environments. Their shale shakers are known for their durability, reliability, and low maintenance, making them an ideal choice for operators looking for long-lasting and cost-effective solutions.In addition to manufacturing shale shakers, {company name} also provides a comprehensive range of services to support their customers. They offer installation, commissioning, and training to ensure proper utilization and maintenance of their equipment. Their dedicated team of professionals is always available to provide technical assistance and support, ensuring smooth operations and minimal downtime.Despite the challenges posed by the COVID-19 pandemic, {company name} has continued to expand its market reach and strengthen its position in the industry. They have focused on research and development, constantly innovating and improving their products to cater to the evolving needs of the market. By prioritizing customer satisfaction and maintaining high standards of quality, {company name} has gained recognition and trust from their customers.As China's oil and gas industry continues to grow, the demand for shale shakers is expected to surge. According to industry experts, China is projected to become one of the largest markets for shale shakers in the coming years. This presents significant opportunities for companies like {company name} to further expand their market share and establish themselves as key players in the industry.In conclusion, the demand for shale shakers in China is driven by the rapid development of the country's oil and gas industry. {company name}, with its extensive range of high-quality shale shakers and excellent customer support, is well-positioned to capitalize on this growing demand. As China aims to boost its domestic production of oil and gas, the need for efficient and reliable drilling equipment, such as shale shakers, will only increase. With its commitment to innovation and customer satisfaction, {company name} is set to play a crucial role in the advancement of China's oil and gas industry.

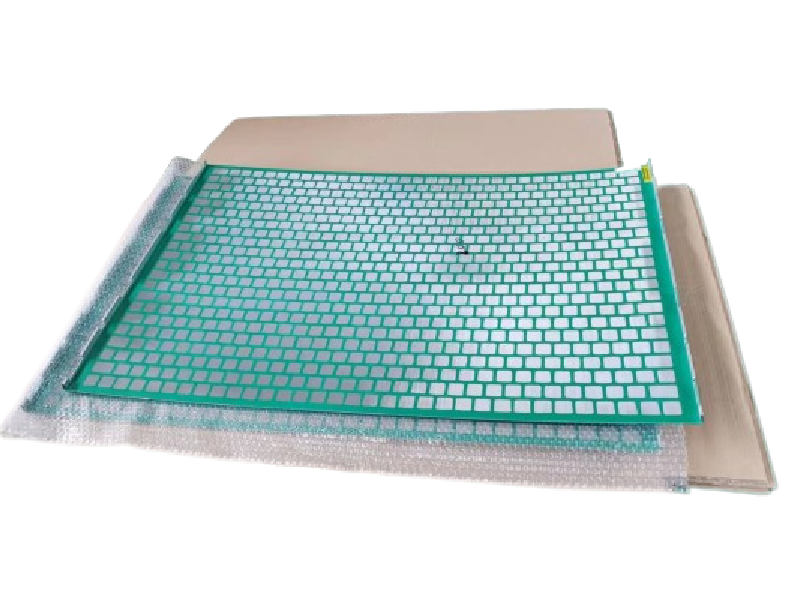

High-performing Shaker Screen for Efficient Mud Shale Shaker Operations

Title: Enhancing Drilling Efficiency with Cutting-Edge Mud Shale ShakersIntroduction:In the world of drilling operations, ensuring optimal performance and efficiency is imperative. One critical component that plays a crucial role in achieving these goals is the Mud Shale Shaker. As China's leading supplier of high-quality Shale Shakers, TR is at the forefront of providing top-notch equipment designed to revolutionize the drilling industry. In this blog post, we will delve into the innovative features of Mud Shale Shakers and their significant impact on drilling efficiency.1. The Role of Mud Shale Shakers:Mud Shale Shakers are indispensable devices used during the drilling process. They are responsible for separating drilling fluid or mud from the cuttings generated while drilling. The efficient removal of unwanted solids from the drilling mud is crucial as it helps maintain the drilling mud's properties, ultimately improving drilling performance.2. Introducing Cutting-Edge Technology:China-based TR has emerged as a leader in the shale shaker market by introducing advanced technology in the form of their Mud Shale Shakers. These state-of-the-art shakers are designed to enhance the efficiency and productivity of drilling operations. The incorporation of innovative features ensures a seamless separation process, contributing significantly to the overall success of any drilling project.3. Mongoose Shaker Screen - Revolutionizing the Industry:One of the standout features of TR's Mud Shale Shakers is the incorporation of the Mongoose Shaker Screen. This technologically advanced screen optimizes the separation process by efficiently removing cuttings from the drilling mud. The durable and high-quality construction of the Mongoose Shaker Screen allows for extended operation life, reducing downtime and maintenance costs.4. Unmatched Performance:TR's Mud Shale Shakers equipped with the Mongoose Shaker Screen are renowned for their exceptional performance. The unique design of the shaker screen ensures optimal vibration, enhanced cuttings conveyance, and increased throughput capacity. As a result, drilling efficiency is significantly improved, reducing overall drilling costs and maximizing resource utilization.5. Ensuring Quality and Reliability:As an established manufacturer and supplier, TR is committed to delivering products of the highest quality. Rigorous quality control measures are applied throughout the manufacturing process to ensure that the Mud Shale Shakers meet or exceed industry standards. TR's dedication to quality ensures that their shaker screens provide reliable and consistent performance in the most demanding drilling environments.6. Pioneering Green Initiatives:Environmental sustainability is a growing concern in the industry, and TR is addressing this issue head-on. The Mud Shale Shakers are designed to minimize waste generation by effectively capturing and separating solids. This eco-friendly approach helps reduce environmental impact while contributing to a greener and cleaner future.Conclusion:TR's Mud Shale Shakers have revolutionized the drilling industry with their cutting-edge technology and exceptional performance. The incorporation of the Mongoose Shaker Screen has proven to be a game-changer in optimizing drilling efficiency. As the leading Chinese manufacturer and supplier, TR continues to set industry standards by providing reliable and high-quality equipment that meets the diverse needs of drilling operations. By choosing TR's Mud Shale Shakers, drilling companies can significantly enhance their performance while contributing to a sustainable future.Keywords: China Mud Shale Shakers, Mud Shale Shaker, drilling efficiency, Mongoose Shaker Screen, TR, cutting-edge technology, drilling operations, drilling fluid, cuttings, shale shaker market, removal of solids, optimal vibration, throughput capacity, quality control measures, environmental sustainability, greener future.