How Desilter Works and Its Key Functions in Industrial Settings

By:Admin

In the oil and gas industry, the process of drilling wells involves the use of drilling fluids to lubricate the drilling bit, carry rock cuttings to the surface, and maintain pressure in the wellbore. These drilling fluids often contain solid particles that need to be removed in order to maintain the effectiveness of the fluid and prevent damage to drilling equipment. This is where desilters come in.

Desilters are a crucial part of the drilling process, as they are responsible for removing solid particles from the drilling fluid. This process ensures that the drilling fluid remains effective and that the wellbore is kept clean and free of debris. One of the leading companies in providing efficient desilter equipment is [Company name].

[Company name] has been a key player in the oil and gas industry for many years, providing a wide range of products and services to support drilling operations. Their desilter equipment is highly regarded for its reliability, efficiency, and durability, making it a preferred choice among drilling professionals.

The function of the desilter is to remove solid particles from the drilling fluid, typically in the range of 15 to 44 microns in size. This is accomplished through a process of centrifugal separation, where the drilling fluid is fed into the desilter unit and subjected to high-speed rotation. This causes the solid particles to separate from the fluid and be expelled from the system, leaving behind clean and effective drilling fluid.

The desilter equipment offered by [Company name] is designed to deliver superior performance in a variety of drilling conditions. Whether it's onshore or offshore, in shallow or deep wells, their desilters are built to withstand the demands of the drilling environment and provide consistent and reliable particle removal.

In addition to their high-performance equipment, [Company name] also offers comprehensive support and service to ensure that their desilters are operating at peak efficiency. This includes on-site installation and training, as well as ongoing maintenance and technical support. By partnering with [Company name], drilling professionals can have confidence in the performance of their desilter equipment and the support of a trusted industry leader.

The importance of effective desilter function cannot be overstated in the drilling process. When solid particles are allowed to remain in the drilling fluid, it can lead to a range of problems, including decreased drilling efficiency, increased equipment wear, and potential damage to the wellbore. By investing in high-quality desilter equipment, drilling professionals can ensure that their operations run smoothly and safely, with minimal risk of downtime or equipment failure.

As the oil and gas industry continues to evolve, the demand for efficient and reliable desilter equipment will remain a top priority for drilling professionals. With the expertise and quality of [Company name]'s desilter products, the industry can look forward to continued success in meeting the challenges of drilling operations.

In conclusion, desilters play a crucial role in the drilling process by removing solid particles from the drilling fluid, and [Company name] stands out as a trusted provider of high-performance desilter equipment. With their commitment to quality, reliability, and customer support, [Company name] is well-positioned to continue supporting the oil and gas industry in meeting the challenges of drilling operations.

Company News & Blog

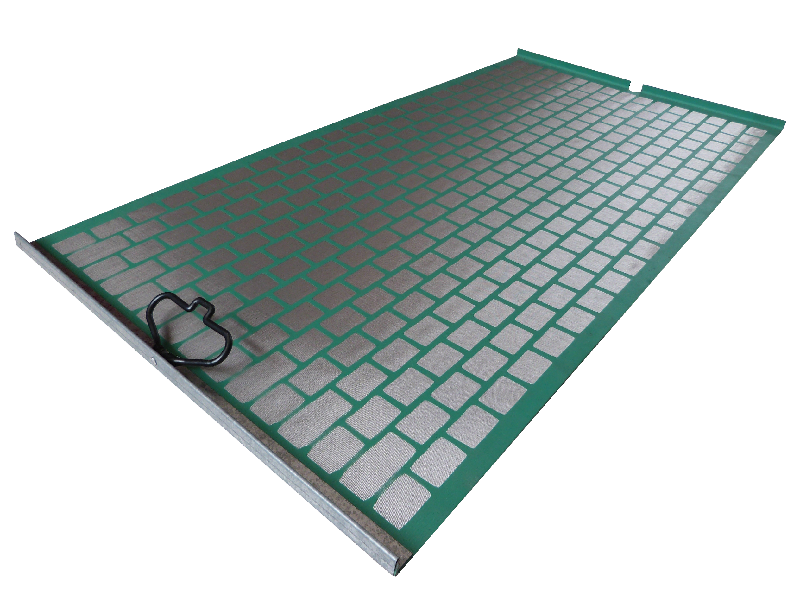

High-performing Shaker Screen for Efficient Mud Shale Shaker Operations

Title: Enhancing Drilling Efficiency with Cutting-Edge Mud Shale ShakersIntroduction:In the world of drilling operations, ensuring optimal performance and efficiency is imperative. One critical component that plays a crucial role in achieving these goals is the Mud Shale Shaker. As China's leading supplier of high-quality Shale Shakers, TR is at the forefront of providing top-notch equipment designed to revolutionize the drilling industry. In this blog post, we will delve into the innovative features of Mud Shale Shakers and their significant impact on drilling efficiency.1. The Role of Mud Shale Shakers:Mud Shale Shakers are indispensable devices used during the drilling process. They are responsible for separating drilling fluid or mud from the cuttings generated while drilling. The efficient removal of unwanted solids from the drilling mud is crucial as it helps maintain the drilling mud's properties, ultimately improving drilling performance.2. Introducing Cutting-Edge Technology:China-based TR has emerged as a leader in the shale shaker market by introducing advanced technology in the form of their Mud Shale Shakers. These state-of-the-art shakers are designed to enhance the efficiency and productivity of drilling operations. The incorporation of innovative features ensures a seamless separation process, contributing significantly to the overall success of any drilling project.3. Mongoose Shaker Screen - Revolutionizing the Industry:One of the standout features of TR's Mud Shale Shakers is the incorporation of the Mongoose Shaker Screen. This technologically advanced screen optimizes the separation process by efficiently removing cuttings from the drilling mud. The durable and high-quality construction of the Mongoose Shaker Screen allows for extended operation life, reducing downtime and maintenance costs.4. Unmatched Performance:TR's Mud Shale Shakers equipped with the Mongoose Shaker Screen are renowned for their exceptional performance. The unique design of the shaker screen ensures optimal vibration, enhanced cuttings conveyance, and increased throughput capacity. As a result, drilling efficiency is significantly improved, reducing overall drilling costs and maximizing resource utilization.5. Ensuring Quality and Reliability:As an established manufacturer and supplier, TR is committed to delivering products of the highest quality. Rigorous quality control measures are applied throughout the manufacturing process to ensure that the Mud Shale Shakers meet or exceed industry standards. TR's dedication to quality ensures that their shaker screens provide reliable and consistent performance in the most demanding drilling environments.6. Pioneering Green Initiatives:Environmental sustainability is a growing concern in the industry, and TR is addressing this issue head-on. The Mud Shale Shakers are designed to minimize waste generation by effectively capturing and separating solids. This eco-friendly approach helps reduce environmental impact while contributing to a greener and cleaner future.Conclusion:TR's Mud Shale Shakers have revolutionized the drilling industry with their cutting-edge technology and exceptional performance. The incorporation of the Mongoose Shaker Screen has proven to be a game-changer in optimizing drilling efficiency. As the leading Chinese manufacturer and supplier, TR continues to set industry standards by providing reliable and high-quality equipment that meets the diverse needs of drilling operations. By choosing TR's Mud Shale Shakers, drilling companies can significantly enhance their performance while contributing to a sustainable future.Keywords: China Mud Shale Shakers, Mud Shale Shaker, drilling efficiency, Mongoose Shaker Screen, TR, cutting-edge technology, drilling operations, drilling fluid, cuttings, shale shaker market, removal of solids, optimal vibration, throughput capacity, quality control measures, environmental sustainability, greener future.

High-Quality Hydraulic Mud Agitator for Solid Control and Oil Drilling in China

, Hydraulic Mud Agitator, Oil Drilling, Solid Control, and China.Solid Control Liquid Mixer Agitator / Hydraulic Mud Agitator For Oil Drilling: The Ultimate Solution for your Drilling NeedsOil drilling is one of the most complex and demanding industries in the world. It requires top-notch equipment and tools to extract valuable resources from the earth's core efficiently. One of the critical components in achieving this is the solid control liquid mixer agitator/hydraulic mud agitator.A solid control liquid mixer agitator/hydraulic mud agitator is a device that ensures the proper mixing of drilling fluids in a mud tank. The mud tank is an integral part of the drilling process as it acts as a reservoir for the drilling mud, which is responsible for cooling and lubricating drill bits, controlling wellbore pressure, and carrying out cuttings from the drill bit to the surface.China has been at the forefront of producing high-quality solid control liquid mixer agitators/hydraulic mud agitators for the oil drilling industry. China's relentless pursuit of quality has made it a leader in the manufacture of fluid mixing equipment, making it a trusted partner to global oil drilling companies.In this blog, we will examine the importance of solid control liquid mixer agitators/hydraulic mud agitators in oil drilling, their features, and why choosing China-made products is a wise decision.Importance of Solid Control Liquid Mixer Agitators/Hydraulic Mud Agitators in Oil DrillingAs earlier mentioned, a mud tank is integral to the oil drilling process. It is responsible for storing drilling mud, which plays a critical role in ensuring a successful drilling process. Drilling mud is a mixture of water, clay, and other chemicals that cool and lubricate drilling bits, control wellbore pressure, carry cuttings from the drill bit to the surface, and prevent the formation of fractures.Maintaining the right consistency and homogeneity of the drilling mud is crucial to the efficiency of the drilling process. This is where the solid control liquid mixer agitator/hydraulic mud agitator comes in. It ensures even distribution of drilling mud, eliminates dead areas, and prevents the formation of lumps and sediments that can clog the drill bit.Features of Solid Control Liquid Mixer Agitators/Hydraulic Mud AgitatorsSolid control liquid mixer agitators/hydraulic mud agitators are built to withstand the harsh conditions of the oil drilling industry. Some of the features that make them suitable for this industry include:1. High-quality materials - Solid control liquid mixer agitators/hydraulic mud agitators are made of top-quality materials such as high-strength steel and abrasion-resistant polyurethane. This makes them durable and robust, capable of withstanding harsh operating conditions.2. Low maintenance - Solid control liquid mixer agitators/hydraulic mud agitators require minimal maintenance, making them cost-effective. This is due to their simple design, which makes it easy to access and replace components.3. High efficiency - Solid control liquid mixer agitators/hydraulic mud agitators are designed for high-efficiency mixing of drilling mud. The agitators are powerful and have a high torque, which ensures even mixing of the drilling mud, preventing the formation of lumps and sediments.Why Choose China-made Solid Control Liquid Mixer Agitators/Hydraulic Mud Agitators?China is a global leader in the manufacture of fluid mixing equipment, including solid control liquid mixer agitators/hydraulic mud agitators. The country has invested heavily in research and development, which has resulted in the production of high-quality products that meet global standards.China-made solid control liquid mixer agitators/hydraulic mud agitators are affordable without compromising on quality. They are also readily available in the market, making them a top choice for oil drilling companies looking for reliable equipment at a reasonable price.ConclusionSolid control liquid mixer agitators/hydraulic mud agitators are indispensable components in the oil drilling industry. Choosing high-quality products such as those from China ensures efficient, safe, and cost-effective drilling operations. With China's commitment to producing top-quality fluid mixing equipment, oil drilling companies can rely on their products to meet their drilling requirements.

Efficient Vertical Cutting Dryer for Improved Solids Control

The revolutionary Vertical Cutting Dryer, developed by a leading provider of drilling waste management solutions, is set to transform the oil and gas industry. This innovative technology is designed to efficiently remove drilled solids from drilling fluids, providing significant cost savings and environmental benefits for companies operating in the sector.The Vertical Cutting Dryer is a key component of the company's comprehensive range of drilling waste management equipment, which is used to separate and recover valuable drilling fluids from solid waste materials. The dryer is capable of processing large volumes of drilled solids, effectively reducing waste volumes and minimizing environmental impact.Designed with a vertical configuration, the cutting dryer utilizes centrifugal force to remove excess liquid from drill cuttings, resulting in drier cuttings and improved overall drilling fluid recovery. The machine's advanced design also reduces the need for dilution and disposal of drilling fluids, leading to substantial cost savings for operators.In addition to its cost-saving benefits, the Vertical Cutting Dryer is also an environmentally friendly solution for managing drilling waste. By effectively separating solids from liquids, the dryer helps to minimize the volume of waste material that requires disposal, reducing the overall environmental footprint of drilling operations.The company behind the Vertical Cutting Dryer is a global leader in providing innovative and sustainable solutions for managing drilling waste. With a strong focus on research and development, the company has continuously pushed the boundaries of technological innovation in the oil and gas industry, delivering products that optimize operational efficiency while reducing environmental impact.The company's extensive experience and expertise in the field of drilling waste management have positioned it as a trusted partner for oil and gas companies seeking sustainable and cost-effective solutions. By offering a comprehensive range of equipment and services, including the Vertical Cutting Dryer, the company helps its clients meet and exceed regulatory requirements while enhancing their overall operational performance.The Vertical Cutting Dryer has already garnered attention from industry experts and operators, who recognize its potential to revolutionize drilling waste management processes. By incorporating this cutting-edge technology into their operations, companies can expect to see improved efficiency, reduced costs, and enhanced environmental stewardship.In a statement, a spokesperson for the company commented, "We are thrilled to introduce the Vertical Cutting Dryer to the market. This innovative technology represents a significant leap forward in the field of drilling waste management, and we believe it will deliver substantial benefits to our clients. By offering a more efficient and sustainable solution for processing drilling waste, we are proud to support our customers in their efforts to operate responsibly and profitably."As the oil and gas industry continues to prioritize sustainability and operational efficiency, the Vertical Cutting Dryer is poised to become an indispensable tool for companies seeking to optimize their drilling waste management processes. With its advanced technology and proven performance, this innovative equipment is set to make a lasting impact on the sector, delivering tangible benefits for both companies and the environment.

Discover the Versatility of Flat Shaker Screens for Effective Solid Separation

FLC 500 Flat Shaker Screen: Revolutionizing the Drilling IndustryThe drilling industry is constantly evolving, with new technologies and equipment constantly emerging to improve efficiency and operational capabilities. One such innovation making waves in the sector is the FLC 500 Flat Shaker Screen, a groundbreaking solution developed by a prominent industry player.Designed to enhance the performance and productivity of drilling operations, the FLC 500 Flat Shaker Screen is revolutionizing the way drilling companies approach their work. With its advanced features and engineering excellence, this game-changing technology has gained significant recognition within the industry.The FLC 500 Flat Shaker Screen is the result of extensive research and development by a leading drilling equipment manufacturer. Leveraging their rich experience and expertise, the company identified a need for an improved shaker screen solution to overcome the challenges faced by drilling companies.One of the key features that sets the FLC 500 Flat Shaker Screen apart from its competitors is its flat design. This innovative construction ensures optimal solids control, allowing for more efficient separation of drilling fluids and solids during the drilling process. The flat screen surface provides a larger area for fluid dewatering, maximizing the screen's capacity and performance.Additionally, the FLC 500 Flat Shaker Screen boasts enhanced durability and longevity. Crafted using high-quality materials and state-of-the-art manufacturing techniques, this robust solution withstands the harsh operating conditions typically encountered in drilling operations. Its extended lifespan not only reduces operational downtime but also significantly lowers maintenance and replacement costs.Furthermore, the FLC 500 Flat Shaker Screen offers exceptional versatility. Compatible with various drilling equipment, it seamlessly integrates with existing systems, ensuring a hassle-free installation process. Its adaptability empowers drilling companies to upgrade their equipment without requiring substantial modifications, thereby improving operational efficiency and saving valuable time.The company behind this breakthrough innovation is known for its commitment to delivering superior technology with a focus on customer satisfaction. With a relentless dedication to research and development, combined with a customer-centric approach, they have earned a reputation as a trusted and reliable partner in the drilling industry.The FLC 500 Flat Shaker Screen is just one example of the company's commitment to innovation. Their extensive product portfolio includes a range of drilling equipment tailored to meet the unique needs and challenges of the industry. From screens to pumps, they offer comprehensive solutions that cater to diverse drilling requirements.In addition to their cutting-edge technology, the company places great emphasis on customer support and service. Their team of highly skilled professionals provides industry-leading technical assistance and on-site support to ensure seamless integration and optimal performance of their equipment. This dedication to customer satisfaction has positioned them as a preferred supplier amongst drilling companies worldwide.The introduction of the FLC 500 Flat Shaker Screen marks a significant milestone in the drilling industry. With its flat design, enhanced durability, and unmatched versatility, it is transforming the way drilling operations are conducted. As companies continue to prioritize efficiency and productivity, this revolutionary technology is set to play a pivotal role in shaping the future of the drilling industry.

Top Quality Drill Rig Components for Efficient Drilling Rig Operations

China drilling rig parts and drill drilling rig drawworks are gaining recognition and popularity in the global market. These high-quality products have become a top choice for companies in need of reliable drilling equipment. With their advanced technology and excellent performance, they have managed to leave a lasting impression on customers worldwide.China is known for its vast manufacturing capabilities, and the drilling rig industry is no exception. The country has made significant progress in this sector and has established itself as a leading manufacturer and exporter of drilling rig parts and drawworks. Chinese companies have successfully filled the gap in the market with their superior products, offering cost-effective solutions to customers around the globe.One of the key players in this industry is a renowned Chinese company, recognized for its excellence in manufacturing drilling rig parts and drawworks. With a strong emphasis on research and development, this company has been able to produce cutting-edge products that meet the highest industry standards. Their commitment to innovation and continuous improvement has helped them stay ahead of the competition and maintain a strong market presence.Advanced technology lies at the core of these drilling rig parts and drawworks. Equipped with state-of-the-art features, they ensure smooth and efficient operations in drilling projects. The company's engineers and technicians work tirelessly to develop new and improved designs, integrating the latest technological advancements into their products. This focus on innovation has driven the company's success and positioned them as industry leaders.Quality is another aspect that sets these Chinese products apart from the competition. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every part and component meets the highest standards. Stringent inspection procedures and rigorous testing guarantee the reliability and longevity of their products. Customers can have peace of mind knowing that they are investing in top-notch equipment that will perform flawlessly on their drilling sites.In addition to their exceptional performance, these drilling rig parts and drawworks also offer great value for money. Chinese manufacturers are known for their competitive pricing, making their products an attractive choice for businesses looking to maximize their return on investment. The combination of affordability and quality has contributed to the growing demand for Chinese drilling rig equipment in the global market.Furthermore, the company's customer-centric approach is another factor that has fueled their success. They prioritize customer satisfaction and aim to establish long-term partnerships with their clients. By providing excellent after-sales service and technical support, they ensure that customers receive the assistance they need throughout the lifespan of their equipment. This commitment to customer care has earned them a loyal customer base and positive reputation.As awareness of the quality and reliability of China's drilling rig parts and drawworks continues to grow, more companies are turning to Chinese manufacturers for their drilling equipment needs. The country's dedication to innovation, emphasis on quality, competitive pricing, and customer focus have positioned them as key players in the global market. With their advanced technology and outstanding performance, Chinese drilling rig parts and drawworks are taking the industry by storm.In conclusion, China's drilling rig parts and drawworks have emerged as trusted and sought-after products in the global market. These high-quality and technologically advanced offerings have captured the attention of companies worldwide. With a commitment to innovation, stringent quality control, competitive pricing, and excellent customer service, Chinese manufacturers have secured their place as market leaders. As demand for drilling equipment continues to grow, China's contribution to the industry is set to remain significant.

Hydrocyclone Desander Manufacturer for Drilling Mud Fluids - Buy Quality Solids Control Desander from China Supplier

The China Desander is an important component in the drilling industry. It is primarily used to remove solid particles, sand, and mud from drilling fluids. This is crucial because these particles can cause a number of problems in the drilling process, such as clogging of equipment and decreased efficiency.One of the most popular types of desanders is the Hydrocyclone Desander. This device works by creating a spinning motion that separates the solid particles from the fluid. The solids are then expelled out of the bottom while the clean fluid is discharged out of the top. This method is highly effective and efficient, making the Hydrocyclone Desander a preferred choice among many drilling companies.One of the leading manufacturers of Hydrocyclone Desanders is GN Solids Control. This China-based company offers high-quality desanders and other equipment for the drilling industry. GN Solids Control has a reputation for producing durable and reliable equipment that can withstand the harsh conditions of drilling.The GN mud desander is a popular product offered by the company. This particular desander is known for its good cones and efficient performance. It is designed to be used in conjunction with other equipment, such as shale shakers and mud cleaners, to provide a complete solids control system for drilling operations.For companies in need of a solids control drilling mud fluids desander, GN Solids Control is a reliable and trustworthy supplier. Their years of experience in the industry and commitment to quality make them a top choice for many drilling companies around the world.In conclusion, the China Desander and Hydrocyclone Desander play an important role in the drilling industry. They are essential for removing solid particles and maintaining the efficiency of drilling equipment. GN Solids Control is a leading supplier of high-quality desanders and other equipment, making them a top choice for companies in need of solids control solutions. With their commitment to quality and customer satisfaction, GN Solids Control is sure to continue to be a top player in the drilling industry for years to come.

Sedimentation Centrifuge and Decanter Centrifuge: Key Innovations in China's Industrial Landscape

China's Sedimentation Centrifuge and Decanter Centrifuge Revolutionizing Industrial ProcessesIn the realm of industrial manufacturing and wastewater treatment, China has become a global leader with its innovative solutions. Among these cutting-edge technologies are the Sedimentation Centrifuge and Decanter Centrifuge, which offer significant advancements in separating liquids and solids efficiently. These centrifuges have garnered international attention due to their exceptional performance, reliability, and affordability. By removing the brand names, we will focus on understanding the broader impact these machines have on the industry.Sedimentation Centrifuge, a vital component in various industries, plays a pivotal role in the separation and dewatering of solid-liquid mixtures. Utilizing centrifugal force, this ingenious equipment accelerates the sedimentation process, efficiently removing solids from liquids. China's Sedimentation Centrifuges have gained widespread acclaim for their exceptional reliability, high separation efficiency, and low energy consumption.The success of the Sedimentation Centrifuge lies in its unique design, which incorporates advanced materials and technologies. These machines utilize efficient rotating bowls that separate solids from liquids based on their different densities. Moreover, the use of state-of-the-art control systems ensures precise control over the process, resulting in superior separation and dewatering outcomes. This technology has found applications in various industries, such as chemical, pharmaceutical, food processing, and wastewater treatment.Similarly, the Decanter Centrifuge has made significant strides in revolutionizing industrial processes across the globe. This versatile equipment specializes in separating solids from liquids, based on differences in density and particle size. Widely used in industries dealing with mining, petroleum, food processing, and wastewater treatment, the Decanter Centrifuge has become an indispensable tool for efficient resource recovery and waste management.China's Decanter Centrifuges have earned a reputation for their exceptional performance and reliability, making them highly sought-after globally. These machines can attain high centrifugal forces, enabling efficient separation of fine particles from liquids. Additionally, advanced control systems ensure precise control over the decanting process, maximizing the separation efficiency. The robust construction and use of corrosion-resistant materials guarantee prolonged machinery lifespan, minimizing maintenance and replacement costs.Both the Sedimentation Centrifuge and Decanter Centrifuge highlight China's commitment to research and development in the field of separation technology. By investing significant resources and expertise into these areas, Chinese manufacturers have created cost-effective, highly efficient alternatives to their international counterparts.The integration of these centrifuges into industrial processes has had profound effects on various sectors. For instance, in the petroleum industry, these machines are used for sludge dewatering, enabling efficient separation of oil and water. In mining, Sedimentation Centrifuges and Decanter Centrifuges are essential for tailings dewatering, reclaiming valuable resources, and mitigating environmental impact. Moreover, in the wastewater treatment sector, these centrifuges have significantly enhanced the efficiency of sludge dewatering, reducing operational costs and environmental footprint.It is worth noting that China's manufacturing capabilities also contribute to the affordability and accessibility of these centrifuges. With the ability to produce these machines at a large scale, Chinese manufacturers offer competitive prices without compromising quality, making them attractive options for various industries worldwide.In conclusion, the Sedimentation Centrifuge and Decanter Centrifuge have become game-changers in the industrial manufacturing and wastewater treatment sectors. China's advancements in these technologies have reshaped how solids and liquids are separated, significantly improving efficiency, reliability, and affordability. As Chinese manufacturers continue to innovate, these centrifuges are poised to play an increasingly pivotal role in global industrial processes.

Newly Released Sandmaster Pump and Centrifugal Pump Gain Attention in China's Latest Mission

China Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump Set to Revolutionize the Pumping Industry[City, Date] - In a groundbreaking move, China's leading pump manufacturer has announced the launch of the highly anticipated Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump. Designed to cater to the growing needs of various industries, these new pumps are set to revolutionize the pumping industry with their cutting-edge technology and unmatched performance.The Nov Mission Sandmaster Pump is a game-changer for the oil and gas industry. Recognizing the challenges faced by operators in the field, this pump has been meticulously engineered to handle sand-laden fluids efficiently. Its robust design ensures smooth operations, even in the harshest conditions. With its high flow rates and superior solids handling capability, the Nov Mission Sandmaster Pump guarantees efficient flow control, reducing downtime and maximizing productivity.Not to be outdone, the Nov Sandmaster Centrifugal Pump brings a new level of excellence to the market. Utilizing the latest advancements in technology, this pump offers exceptional performance across a wide range of applications. Be it the agricultural sector or the chemical industry, the Nov Sandmaster Centrifugal Pump is well-equipped to handle the most demanding pumping requirements. Its efficient design ensures reliable and consistent performance, making it an ideal choice for various industries.These remarkable pumps are the result of the relentless pursuit of excellence by China's leading pump manufacturer. With decades of experience and a commitment to innovation, they have consistently delivered premium quality products to clients worldwide. Their state-of-the-art manufacturing facilities, coupled with a dedicated team of professionals, have positioned them as industry leaders.The Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump boast several features that set them apart from their competitors. Crafted from high-quality materials, they offer exceptional durability, ensuring a long operational lifespan. Their user-friendly design allows for easy maintenance, minimizing downtime and reducing overall costs. Furthermore, their compact size and lightweight construction make them convenient to install and transport, further enhancing their utility.Recognizing the need to address environmental concerns, these pumps have been engineered with energy efficiency in mind. The Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump optimize power consumption without compromising performance. By reducing energy waste, industries can significantly lower their carbon footprint, contributing to a greener future.The launch of the Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump has garnered widespread attention in the global market. Industry experts and professionals alike eagerly await the opportunity to harness the transformative power of these cutting-edge pumps. With their versatile applications, unparalleled performance, and commitment to sustainability, these pumps are set to reshape the pumping industry as we know it.China's leading pump manufacturer remains committed to pushing the boundaries of innovation. As they continue to invest in research and development, their goal is to deliver groundbreaking solutions that cater to evolving industry needs. The Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump are a testament to their unwavering dedication to excellence.As industries seek more efficient and reliable pumping solutions, the Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump leading the charge, setting a new precedent for excellence in the pumping industry. With these state-of-the-art pumps, businesses can expect enhanced performance, reduced costs, and a more sustainable future.About [Company Introduction][Company Introduction] is a leading pump manufacturer based in China. With a rich heritage and years of experience, they have consistently delivered top-of-the-line pumping solutions to clients worldwide. Their commitment to excellence and continuous innovation has made them a trusted name in the industry. With the launch of the Nov Mission Sandmaster Pump and Nov Sandmaster Centrifugal Pump, they are poised to transform the pumping industry, providing unmatched performance and reliability.

Revolutionary Solution: Discover the Power of a High-performance Mud Mixer

Title: Innovative Mud Mixing Solution Optimizes Drilling Efficiency in the Oil and Gas IndustryIntroduction:In the oil and gas industry, the efficient extraction of resources relies heavily on advanced technology and equipment. A key component crucial to drilling operations is the mud mixer, a device that blends drilling fluids or mud to maintain stability and enhance performance during drilling processes. Addressing the increasing demand for improved efficiency and performance, a leading engineering company has introduced their cutting-edge Jet Mud Mixer system, revolutionizing the field of drilling and excavation.Body:1. Understanding the Importance of Mud Mixing: The drilling process generates enormous amounts of heat and pressure, demanding fluids that effectively cool, lubricate, and stabilize the drill bit. Mud mixing systems play a critical role by preparing drilling fluids that are essential for successful drilling operations. The fluids facilitate removing cuttings from the wellbore, preventing formation damage, controlling well pressure, and stabilizing the excavation.2. Introducing the Innovative Jet Mud Mixer System: Recognizing the need for a high-performance and efficient mud mixing solution, [Company Name] has developed the Jet Mud Mixer system. This technology combines precise engineering and state-of-the-art design, enabling drilling companies to achieve unparalleled performance in their operations. By integrating advanced processes and materials, this mud mixer surpasses industry standards, providing enhanced drilling efficiency and cost-effectiveness.3. Cutting-edge Features and Functionality: The Jet Mud Mixer system boasts several innovative features that set it apart from existing mud mixing solutions: a. Superior Mixing Performance: [Company Name]'s technology combines robust jet nozzles with a high-power discharge pump, ensuring thorough blending of drilling fluids at optimum consistency and density. b. Versatility and Scalability: The Jet Mud Mixer system is designed to accommodate a wide range of drilling environments, from small-scale onshore projects to large offshore rigs, providing adaptability and scalability for various drilling operations. c. Precision Controls: Equipped with user-friendly controls, drilling operators can easily configure the desired mud consistency, density, and flow rates, improving overall operational control and efficiency. d. Enhanced Safety Measures: Complying with stringent safety regulations, this cutting-edge system incorporates safety features such as emergency stop mechanisms, leakage protection, and excess pressure triggers, ensuring the well-being of personnel and the environment.4. Optimizing Drilling Efficiency and Cost-effectiveness: The Jet Mud Mixer system offers significant advantages to drilling companies seeking to enhance their operational efficiency and reduce costs: a. Increased Drilling Rates: With precise control of drilling mud density and composition, the Jet Mud Mixer system enables faster drilling rates, reducing overall drilling time and costs. b. Reduced Waste and Environmental Impact: By systematically and accurately managing the drilling fluids, this advanced mixing solution minimizes waste and environmental impact, promoting sustainability within the industry. c. Lower Maintenance and Downtime: The robust construction and durability of the Jet Mud Mixer system ensure minimal maintenance requirements. Consequently, downtime caused by equipment breakdowns is significantly reduced, optimizing overall drilling productivity. d. Enhanced Operator Safety: Incorporating safety mechanisms and protocols, the system prioritizes operator safety during mud mixing operations, minimizing accidents and injuries.Conclusion:The introduction of the Jet Mud Mixer system by [Company Name] marks a significant advancement in drilling technology within the oil and gas industry. With its cutting-edge features, precision controls, and focus on efficiency, this innovative mud mixing solution enhances drilling rates, reduces environmental impact, and improves overall operational cost-effectiveness. Embarking on a journey towards a more sustainable and efficient future, [Company Name] is revolutionizing the drilling industry, setting new benchmarks for performance and safety.

Discover the Latest Updates on Cutting-edge Pumps and Centrifugal Water Pumps in China

China's Pumps and Centrifugal Water Pumps Revolutionize Industrial ProcessesIn today's fast-paced industrial world, the need for efficient and reliable equipment is higher than ever. One company that has been at the forefront of meeting these demands is China Pumps, a leading manufacturer of centrifugal water pumps. With their cutting-edge technology and dedication to excellence, China Pumps has revolutionized various industrial sectors, improving productivity and ensuring economic growth.Established in 1996, China Pumps has grown to become a global leader in the pump manufacturing industry. The company's success can be attributed to its unwavering commitment to research and development, ensuring that their products are constantly evolving to meet the ever-changing needs of their customers.One of China Pumps' standout products is their range of centrifugal water pumps. These pumps are specifically designed to move water through the use of an impeller, generating high flow rates and delivering substantial amounts of water at a consistent pressure. With their efficient and robust design, centrifugal water pumps are ideal for various applications, including irrigation, cooling systems, wastewater treatment, and more.The versatility and efficiency of China Pumps' centrifugal water pumps make them a valuable asset in industries such as agriculture, manufacturing, and construction. For instance, in agriculture, these pumps have been pivotal in improving irrigation systems, ensuring that farmers can efficiently water their crops while minimizing water wastage. Additionally, in the manufacturing sector, these pumps play a vital role in maintaining cooling systems for machinery, preventing overheating and enhancing overall productivity.China Pumps' centrifugal water pumps are not only highly efficient but also durable and reliable. Constructed with high-quality materials, these pumps can withstand demanding conditions, ensuring longevity and minimal maintenance requirements. Their advanced technology and innovative design contribute to increased reliability, reducing the risk of downtime and costly repairs for industrial operations.Moreover, China Pumps' commitment to environmental sustainability is reflected in their highly efficient pumps. With the rising global concern over water scarcity and energy consumption, their centrifugal water pumps have been designed to minimize energy usage, reducing carbon footprint and operating costs. By utilizing innovative features such as variable speed drives and optimized impeller designs, these pumps help industries achieve significant energy savings without compromising performance.China Pumps' dedication to customer satisfaction extends beyond their product portfolio. The company provides comprehensive after-sales services, including installation assistance, maintenance support, and prompt customer service. This ensures that their clients receive the necessary guidance and assistance throughout the lifespan of the pumps, maximizing their productivity and operational efficiency.As a testament to their success, China Pumps has received numerous accolades and certifications, including ISO 9001 and CE certifications. These recognitions reinforce the company's commitment to quality and customer satisfaction, further solidifying their position as a trusted and reliable pump manufacturer in the global market.Looking ahead, China Pumps aims to continue pushing the boundaries of pump technology, introducing advancements that further enhance efficiency, reliability, and sustainability. Through ongoing research and development, the company strives to meet the ever-growing demands of the industrial sector, enabling businesses to thrive in a competitive marketplace.In conclusion, China Pumps' centrifugal water pumps have revolutionized industrial processes, providing businesses across various sectors with efficient, reliable, and environmentally-friendly solutions. With their advanced technology, durability, and commitment to customer satisfaction, China Pumps continues to be a driving force in the pump manufacturing industry, contributing to economic growth and sustainable development.