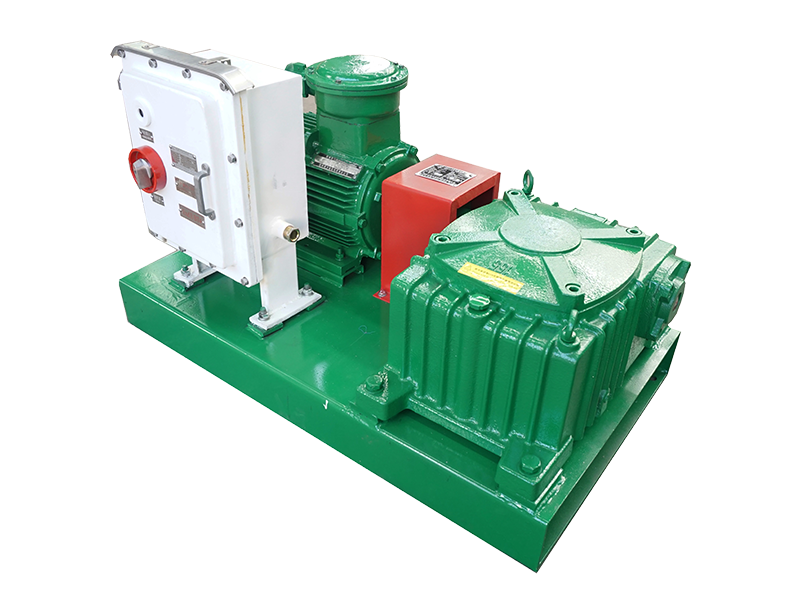

Highly Efficient Mud Mixing System for Industrial Applications

By:Admin

{Company name} is a leading provider of mud mixing systems and has gained a strong reputation for delivering high-quality and innovative solutions to the oil and gas industry. With a focus on technological advancement and customer satisfaction, the company has become a preferred choice for many drilling contractors and operators.

The mud mixing system offered by {company name} is designed to meet the specific requirements of each drilling project. It is equipped with state-of-the-art technology and features that ensure precise control over the mud properties, such as viscosity, weight, and rheological characteristics. This level of control is crucial in maintaining the stability of the wellbore and ensuring maximum efficiency during the drilling process.

One of the key advantages of {company name}'s mud mixing system is its ability to handle a wide range of drilling fluids, including water-based, oil-based, and synthetic muds. This versatility allows contractors to adapt to different geological conditions and challenges, ultimately improving the overall performance and productivity of their drilling operations.

In addition to its technical capabilities, {company name} also places a strong emphasis on the reliability and durability of its mud mixing systems. These systems are built to withstand the harsh and demanding conditions of oil and gas drilling, ensuring long-term performance and minimal downtime. This commitment to quality has earned {company name} a loyal customer base and a strong reputation in the industry.

Furthermore, {company name} provides comprehensive support and services for its mud mixing systems, including installation, training, maintenance, and technical assistance. This level of support ensures that customers can maximize the potential of their equipment and achieve their drilling objectives with confidence.

In recent years, {company name} has continued to innovate and expand its range of mud mixing systems, incorporating the latest advancements in technology and industry best practices. The company's commitment to continuous improvement has led to the development of more advanced and efficient solutions, further solidifying its position as a leader in the field.

As the demand for energy continues to grow, the importance of efficient and reliable drilling operations has become increasingly critical. {Company name}'s mud mixing systems play a vital role in this process, providing the necessary tools and support for successful and cost-effective drilling projects.

With a strong focus on quality, reliability, and customer satisfaction, {company name} has established itself as a trusted partner for drilling contractors and operators worldwide. Its innovative mud mixing systems have set new standards for performance and efficiency, contributing to the success of countless drilling operations.

In conclusion, {company name} has proven to be a driving force in the advancement of mud mixing systems for the oil and gas industry. Through its commitment to excellence and customer-focused approach, the company continues to play a pivotal role in shaping the future of drilling operations. As the industry evolves, {company name} remains at the forefront, delivering cutting-edge solutions that meet the ever-changing demands of the oil and gas sector.

Company News & Blog

Quality Sand Investment Casting and Coated Sand Investment Castings in China

China Sand Investment Casting and Coated Sand Investment Castings have become increasingly popular in the manufacturing industry due to their superior quality and cost-effectiveness. With the rise of demand for precision-engineered components in various industries, the investment casting process has become an integral part of the production of high-quality and complex parts.Investment casting, also known as lost-wax casting, is a manufacturing process that involves creating a wax pattern that is coated with a ceramic material. This pattern is then melted, leaving a hollow ceramic shell that is filled with molten metal to create the final part. This process allows for the production of parts with intricate shapes, thin walls, and fine details, making it a preferred method for the production of components in industries such as aerospace, automotive, and marine.China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise in the production of high-quality precision components. With state-of-the-art facilities and a highly skilled workforce, they are able to meet the most demanding requirements of their customers, providing cost-effective solutions for complex and critical components.The investment casting process offers numerous benefits, including the ability to produce parts with tight tolerances, excellent surface finish, and complex geometry. This makes it a preferred choice for manufacturers looking to produce high-performance components that meet stringent quality standards.China Sand Investment Casting and Coated Sand Investment Castings specialize in the production of a wide range of components, including turbine blades, impellers, and other complex parts used in the aerospace and automotive industries. Their expertise in producing components with high temperature and corrosion resistance makes them a trusted partner for manufacturers requiring precision-engineered parts for critical applications.In addition to traditional investment casting, China Sand Investment Casting and Coated Sand Investment Castings also offer coated sand investment casting, a process that involves coating sand with a refractory material to create a mold for casting. This process is particularly suitable for the production of large and heavy parts, offering cost-effective solutions for manufacturers looking to produce components with complex shapes and structures.The company's commitment to quality and innovation has made them a preferred choice for manufacturers looking for reliable and cost-effective investment casting solutions. With a strong focus on research and development, they continue to invest in new technologies and processes to ensure that they are at the forefront of the industry, offering their customers the best possible solutions for their production needs.With a global presence and a strong reputation for quality and reliability, China Sand Investment Casting and Coated Sand Investment Castings are well-positioned to meet the growing demand for precision-engineered components in various industries. Their commitment to excellence and customer satisfaction has made them a trusted partner for manufacturers worldwide, providing them with the high-quality components they need to stay competitive in today's market.In conclusion, China Sand Investment Casting and Coated Sand Investment Castings are leading providers of investment casting services, offering a wide range of capabilities and expertise to meet the most demanding requirements of their customers. With a strong focus on quality, innovation, and customer satisfaction, they are well-positioned to continue their success and remain a preferred partner for manufacturers looking for cost-effective and reliable solutions for their production needs.

Revolutionary Solution: Discover the Power of a High-performance Mud Mixer

Title: Innovative Mud Mixing Solution Optimizes Drilling Efficiency in the Oil and Gas IndustryIntroduction:In the oil and gas industry, the efficient extraction of resources relies heavily on advanced technology and equipment. A key component crucial to drilling operations is the mud mixer, a device that blends drilling fluids or mud to maintain stability and enhance performance during drilling processes. Addressing the increasing demand for improved efficiency and performance, a leading engineering company has introduced their cutting-edge Jet Mud Mixer system, revolutionizing the field of drilling and excavation.Body:1. Understanding the Importance of Mud Mixing: The drilling process generates enormous amounts of heat and pressure, demanding fluids that effectively cool, lubricate, and stabilize the drill bit. Mud mixing systems play a critical role by preparing drilling fluids that are essential for successful drilling operations. The fluids facilitate removing cuttings from the wellbore, preventing formation damage, controlling well pressure, and stabilizing the excavation.2. Introducing the Innovative Jet Mud Mixer System: Recognizing the need for a high-performance and efficient mud mixing solution, [Company Name] has developed the Jet Mud Mixer system. This technology combines precise engineering and state-of-the-art design, enabling drilling companies to achieve unparalleled performance in their operations. By integrating advanced processes and materials, this mud mixer surpasses industry standards, providing enhanced drilling efficiency and cost-effectiveness.3. Cutting-edge Features and Functionality: The Jet Mud Mixer system boasts several innovative features that set it apart from existing mud mixing solutions: a. Superior Mixing Performance: [Company Name]'s technology combines robust jet nozzles with a high-power discharge pump, ensuring thorough blending of drilling fluids at optimum consistency and density. b. Versatility and Scalability: The Jet Mud Mixer system is designed to accommodate a wide range of drilling environments, from small-scale onshore projects to large offshore rigs, providing adaptability and scalability for various drilling operations. c. Precision Controls: Equipped with user-friendly controls, drilling operators can easily configure the desired mud consistency, density, and flow rates, improving overall operational control and efficiency. d. Enhanced Safety Measures: Complying with stringent safety regulations, this cutting-edge system incorporates safety features such as emergency stop mechanisms, leakage protection, and excess pressure triggers, ensuring the well-being of personnel and the environment.4. Optimizing Drilling Efficiency and Cost-effectiveness: The Jet Mud Mixer system offers significant advantages to drilling companies seeking to enhance their operational efficiency and reduce costs: a. Increased Drilling Rates: With precise control of drilling mud density and composition, the Jet Mud Mixer system enables faster drilling rates, reducing overall drilling time and costs. b. Reduced Waste and Environmental Impact: By systematically and accurately managing the drilling fluids, this advanced mixing solution minimizes waste and environmental impact, promoting sustainability within the industry. c. Lower Maintenance and Downtime: The robust construction and durability of the Jet Mud Mixer system ensure minimal maintenance requirements. Consequently, downtime caused by equipment breakdowns is significantly reduced, optimizing overall drilling productivity. d. Enhanced Operator Safety: Incorporating safety mechanisms and protocols, the system prioritizes operator safety during mud mixing operations, minimizing accidents and injuries.Conclusion:The introduction of the Jet Mud Mixer system by [Company Name] marks a significant advancement in drilling technology within the oil and gas industry. With its cutting-edge features, precision controls, and focus on efficiency, this innovative mud mixing solution enhances drilling rates, reduces environmental impact, and improves overall operational cost-effectiveness. Embarking on a journey towards a more sustainable and efficient future, [Company Name] is revolutionizing the drilling industry, setting new benchmarks for performance and safety.

Exploring the Efficiency of Mud Shale Shakers in China's Drilling Industry

China Mud Shale Shakers and Mud Shale Shaker: Making Oil Drilling Faster and CleanerShale shakers are used to separate drilling cuttings from drilling mud, which is essential for the smooth functioning of oil drilling operations. China Mud Shale Shakers and Mud Shale Shaker are two of the leading manufacturers of shale shakers. Their high-quality products have won the hearts of many clients in the oil and gas industry, including drilling contractors, rig manufacturers, and oil companies. This article will take a closer look at these two companies and their products.China Mud Shale ShakersChina Mud Shale Shakers was established in 1954 and is one of the oldest shale shaker manufacturers in China. The company is headquartered in Tangshan, Hebei Province. It has a state-of-the-art manufacturing plant and a team of highly qualified engineers and technicians. The company is committed to providing its clients with innovative and efficient solutions for drilling waste management.China Mud Shale Shakers offers a wide range of shale shakers, including linear motion shale shakers, balanced elliptical motion shale shakers, and dual motion shale shakers. All of their products are designed to handle high-capacity solids and offer low maintenance costs. The company has a strong focus on research and development and has several patents to its name.One of the flagship products of China Mud Shale Shakers is its linear motion shale shaker, which is designed to handle high-capacity solids. The shaker features a unique screen deck with a three-layer structure. The top layer is used for coarse screening, the middle layer for fine screening, and the bottom layer for final recovery of the mud. The shaker is also equipped with adjustable deck angles, which ensures proper fluid handling and screen performance.Mud Shale ShakerMud Shale Shaker was established in 2014 and is a relatively new shale shaker manufacturer. The company is headquartered in Beijing, China, and has a modern manufacturing facility. Mud Shale Shaker offers a range of high-quality shale shakers, including linear motion shale shakers and balanced elliptical motion shale shakers.Mud Shale Shaker's products are designed to handle high-capacity solids, offer low maintenance costs, and are easy to operate. The company has a strong focus on customer service and aims to build long-term relationships with its clients. Mud Shale Shaker's products have won many accolades and are well-regarded in the oil and gas industry.One of the flagship products of Mud Shale Shaker is its linear motion shale shaker, which is designed to handle high-capacity solids. The shaker features a unique dual-motor configuration, which ensures high screening efficiency and reduced vibration. The shaker is also equipped with adjustable deck angles, which ensures proper fluid handling and screen performance.ConclusionIn conclusion, China Mud Shale Shakers and Mud Shale Shaker are two highly respected shale shaker manufacturers in China. Both companies have a strong focus on innovation, quality, and customer service. They offer a range of high-quality shale shakers that are designed to handle high-capacity solids and offer low maintenance costs. Whether you are a drilling contractor, rig manufacturer, or an oil company, China Mud Shale Shakers and Mud Shale Shaker can provide you with innovative and efficient solutions for drilling waste management.

High Quality 240m3/h Mud Cleaning Equipment with 4" Desilter Cones and Bottom Shale Shaker - Efficient Mud Cleaning Systems

High-quality Shale Shaker Screen for Solid Control or Desander Applications

Title: Maximizing Efficiency with FLC 48-30 Shaker Screens: A Comprehensive ReviewIntroduction: In the realm of solid control and desanding equipment, the FLC 48-30 Shaker Screens have revolutionized the industry with their impeccable performance and reliable functionality. Designed to optimize efficiency, these Derrick shaker screens have become synonymous with superior quality and exceptional durability. In this blog post, we will delve deeper into the features and benefits of FLC 48-30 Shaker Screens, shedding light on their immense potential in enhancing solid control processes.Understanding FLC 48-30 Shaker Screens:With the key goal of achieving maximum efficiency during solid control or desanding operations, the FLC 48-30 Shaker Screens have emerged as the ideal choice for professionals across industries. These screens are tailor-made to fit the FLC 48-30 / 2000 PWP Shale Shaker, offering a perfect amalgamation of precision and robustness.Key Features:1. Impressive Filtering Capacity: The FLC 48-30 Shaker Screens boast a high-quality mesh material, ensuring exceptional particle separation and perfect cuttings disposal. This enables operators to achieve finer filtration, leading to improved solids removal and enhanced drilling fluid recovery.2. Enhanced Durability: Built to withstand demanding working conditions, FLC 48-30 Shaker Screens exhibit remarkable longevity. Thanks to their superior construction, these screens can withstand heavy usage and maintain their structural integrity, ensuring prolonged operational efficiency.3. Easy Installation and Maintenance: FLC 48-30 Shaker Screens feature user-friendly designs that simplify installation and maintenance processes. With their seamless installation process, these screens enable smooth integration into existing equipment, saving precious time and resources.4. Compatibility and Versatility: These Derrick shaker screens are highly compatible and can be easily fitted into other shaker brands, allowing operators to optimize their existing shaker systems without significant modifications. This versatility provides cost-effective solutions for upgrading and improving solid control operations.Benefits of FLC 48-30 Shaker Screens:1. Optimal Solids Control: The FLC 48-30 Shaker Screens' efficient particle separation capabilities promote higher solids control efficiency, resulting in improved drilling fluid quality. By ensuring finer filtration, these screens minimize the potential for blockages and equipment downtime.2. Cost-Efficiency: By integrating FLC 48-30 Shaker Screens into the solid control process, operators can achieve significant cost savings. The screens' ability to effectively remove solids from drilling mud leads to reduced waste volume, prolonged equipment lifespan, and diminished environmental impact.3. Enhanced Drilling Fluid Recovery: With their exceptional filtering capabilities, these shaker screens enable improved drilling fluid recovery. The removal of unwanted solids reduces fluid wastage, allowing operators to minimize costs associated with fluid replacement.4. Reduced Equipment Maintenance: FLC 48-30 Shaker Screens' efficient particle separation helps to prevent excessive wear on downstream equipment, such as centrifuges and desanders. This leads to decreased maintenance needs and extends the lifespan of auxiliary systems, resulting in reduced operational downtime.Conclusion:As the solid control and desanding processes continue to play a vital role in various industries, the FLC 48-30 Shaker Screens have emerged as an indispensable tool for optimizing efficiency. Their reliability, durability, and impressive filtering capacity make them the prime choice for enhancing solids control operations. By investing in these Derrick shaker screens, operators can unlock substantial gains in terms of cost-efficiency, improved drilling fluid recovery, and reduced equipment maintenance. Embrace the power of FLC 48-30 Shaker Screens today and take your solid control processes to new heights of excellence.

Mud Pump Parts: Find Top Small Mud Pump Manufacturers and Suppliers in China

Rigs.China Mud Pump: An Overview of its Importance in Drilling OperationsChina is one of the world's largest producers of oil and natural gas, making it a leading player in the global energy industry. Drilling rigs are an essential component of oil and gas extraction, and the importance of mud pumps in drilling operations cannot be overstated. Mud pumps are used to pump drilling fluids or mud down the drill string and out the drill bit, where it cools and lubricates the drilling assembly, and carries the drilled cuttings back up to the surface.Mud pumps play a crucial role in ensuring the success of drilling operations, and their effectiveness and reliability can often determine the profitability of oil and gas drilling ventures. When it comes to mud pumps, China has been at the forefront of innovation and advancement, producing some of the most powerful and efficient mud pumps used in drilling rigs worldwide.China Mud Pump Parts: Enhancing the Performance and Longevity of Mud PumpsMud pumps are complex machines made up of several components, each playing a critical role in their performance and reliability. The importance of mud pump parts cannot be underestimated, as they are crucial factors in the overall efficiency of mud pumps and the success of drilling operations. China Mud Pump Parts manufacturers have been leading the way when it comes to producing high-quality mud pump parts that can withstand the rigors of drilling operations.The components of a mud pump are susceptible to wear and tear and require regular maintenance and replacement to ensure their optimal functioning. By using China Mud Pump Parts, drilling companies can benefit from longer-lasting components designed to withstand harsh drilling environments, minimizing downtime, and maintenance costs. Investing in China Mud Pump Parts guarantees drilling companies the superior performance, longevity, and reliability of their mud pumps, ensuring the success of their drilling operations.Small Mud Pump: An Ideal Alternative for Light-Duty Drilling OperationsWhen it comes to drilling operations, not all projects require large, heavy-duty mud pumps. In light-duty drilling operations, small mud pumps are a viable alternative, designed to handle relatively low volumes of drilling fluids or mud. Small Mud Pump Manufacturers in China have been producing high-quality and reliable small mud pumps that can handle a range of drilling operations, from mining to geothermal drilling.Small mud pumps are an excellent solution for projects where limited space is an issue, and where high volumes of drilling fluid are not necessary. They are also ideal for mining operations that require the constant removal of groundwater to prevent flooding. Small mud pumps offer a cost-effective and efficient solution to light-duty drilling operations, making them a popular option for drilling companies worldwide.ConclusionMud pumps are a critical component of drilling rigs, and their reliability and efficiency can make or break drilling operations. China has been at the forefront of producing some of the most powerful and efficient mud pumps worldwide, and their China Mud Pump Parts are equally as impressive. Small Mud Pump Manufacturers in China are also producing high-quality small mud pumps that are ideal for light-duty drilling operations.Investing in mud pumps, mud pump parts, and small mud pumps from China's leading manufacturers is a guarantee of superior performance, longevity, and reliability. At (need to remove brand name), we pride ourselves on being the leading China Mud Pump and Mud Pump for Drilling Rigs supplier, providing our clients with the best mud pumps and mud pump parts available on the market. Visit our site today and take advantage of our premium products and ensure the success of your drilling operations.

Effective Mud Gas Separator Design for Oil and Gas Operations

Mud Gas Separator Design Innovations by Leading CompanyIn the oil and gas industry, the need to effectively separate gas from drilling fluid has led to the development of advanced technologies such as the Mud Gas Separator (MGS). One of the leading companies in this field, with a proven track record of innovation and excellence, is {}. Their latest MGS design is set to revolutionize the industry by offering improved performance and efficiency.Established in {}, {} has been at the forefront of developing cutting-edge solutions for the oil and gas sector. With a team of highly skilled engineers and researchers, the company has consistently delivered state-of-the-art equipment that meets the evolving needs of the industry. The company's commitment to quality, safety, and environmental protection has earned them a stellar reputation as a trusted partner for oil and gas companies around the world.The latest Mud Gas Separator design by {} is the result of years of research and development. This innovative technology is designed to effectively separate and vent gas from drilling fluid, ensuring the safety of personnel and equipment on drilling rigs. The new design incorporates advanced features that enhance performance and reliability, making it an invaluable tool for oil and gas operations.One of the key features of the new Mud Gas Separator design is its enhanced gas-liquid separation efficiency. Thanks to innovative engineering and advanced materials, the MGS is capable of effectively capturing and removing gas from drilling fluid, even in high-pressure and high-temperature environments. This not only improves safety on drilling rigs but also minimizes the risk of equipment damage and downtime.Furthermore, the new MGS design also incorporates a compact and lightweight construction, making it easier to transport and install on drilling rigs. This innovative approach to design and engineering reflects {}'s commitment to practicality and ease of use, ensuring that their products meet the needs of their clients in the field.In addition to its performance and portability, the new Mud Gas Separator design by {} also integrates advanced safety features. These include robust gas venting systems and fail-safe mechanisms, which are essential for ensuring the wellbeing of personnel and the protection of the environment during drilling operations.{}'s Mud Gas Separator design is also designed to be user-friendly, with intuitive controls and maintenance features that make it easier for operators to monitor and service the equipment. This focus on usability and accessibility is a testament to {}'s customer-centric approach, ensuring that their products are not only technologically advanced but also practical and easy to operate.With the launch of their latest Mud Gas Separator design, {} reinforces their position as a leading innovator in the oil and gas industry. This new technology is set to raise the bar for gas-liquid separation on drilling rigs, offering unparalleled performance, reliability, and safety. As the industry continues to evolve, {} remains dedicated to developing solutions that address the challenges of today and anticipate the needs of tomorrow. Their commitment to excellence and innovation is evident in every aspect of their business, making them a trusted partner for oil and gas companies worldwide.

Powerful Hydraulic Pump for Mission Sandmaster

Mission Sandmaster Pump is a revolutionary product that has gained immense popularity in the industry for its innovative features and exceptional performance. This state-of-the-art pump is designed to meet the increasing demand for efficient and reliable pumping solutions in the oil and gas sector. Mission Sandmaster Pump is manufactured by a leading company in the industry, which has a long-standing reputation for delivering high-quality and advanced products.The company responsible for manufacturing Mission Sandmaster Pump is committed to providing innovative solutions to the oil and gas industry. With a strong focus on research and development, the company has been able to create cutting-edge products that meet the evolving needs of the industry. The company is known for its extensive expertise in engineering, manufacturing, and servicing a wide range of pumping solutions, and it has set new standards for reliability and performance in the industry.Mission Sandmaster Pump is designed to handle the toughest pumping challenges in the oil and gas sector. It is specifically engineered to efficiently handle abrasive and corrosive fluids, making it the ideal solution for demanding applications. The pump is capable of handling high viscosity fluids and solid-laden slurries, ensuring consistent and reliable performance in the most challenging environments. Its robust construction and advanced design make it a versatile and reliable choice for a wide range of pumping applications.One of the key features of Mission Sandmaster Pump is its cutting-edge technology, which sets it apart from traditional pumping solutions. The pump is equipped with a high-efficiency impeller and casing design, which minimizes wear and maximizes uptime. This innovative design ensures that the pump can maintain peak performance even in the harshest operating conditions, reducing downtime and maintenance costs for operators. Additionally, the pump is designed to be easily customizable to meet specific application requirements, providing operators with a flexible and reliable solution for their pumping needs.In addition to its advanced technology, Mission Sandmaster Pump is also known for its exceptional reliability and durability. The pump is built to withstand the most demanding operating conditions, providing operators with a long-lasting and cost-effective pumping solution. Its rugged construction and high-quality materials ensure that the pump can withstand the wear and tear of continuous operation, delivering reliable performance over an extended service life. This unparalleled durability makes Mission Sandmaster Pump a preferred choice for operators looking for a dependable and low-maintenance pumping solution.Furthermore, Mission Sandmaster Pump is supported by a comprehensive service network provided by the manufacturing company, ensuring that operators receive the support they need to maximize the performance and lifespan of their pumps. The company has a team of highly skilled technicians and engineers who are dedicated to providing exceptional service and support for Mission Sandmaster Pump. From installation and commissioning to maintenance and repair, the company's service network is committed to delivering unmatched support to operators, ensuring that their pumping systems operate at their best at all times.In conclusion, Mission Sandmaster Pump is a game-changing product that has redefined pumping solutions in the oil and gas industry. Its advanced technology, exceptional reliability, and comprehensive service network make it a superior choice for operators looking for efficient and dependable pumping solutions. Supported by a leading company with a proven track record in the industry, Mission Sandmaster Pump is set to continue its success and establish itself as the go-to pumping solution for the most demanding applications in the oil and gas sector.

Discover the Benefits of Utilizing a High-Quality Drilling Mud Desilter

Drilling Mud Desilter – The Solution to Efficient Drilling OperationsDrilling operations in the oil and gas industry involve various stages and processes to ensure the successful extraction of hydrocarbons. One such stage is drilling mud cleaning, which is vital to ensure the effectiveness of the drilling process. Drilling mud, a mixture of fluids, solids, and chemicals, is used to lubricate and cool the drill bit, as well as to transport the drilled cuttings to the surface. Over time, the drilling mud becomes contaminated with solids and other impurities, which can cause operational problems, impede drilling efficiency, and could even lead to equipment failure. To address these concerns, companies are turning to Drilling Mud Desilters.Drilling Mud Desilters are equipment designed to remove impurities from drilling mud, leaving behind a clean and reusable liquid. The process involves separating solids from liquids, ensuring that only the necessary components remain, and the contaminants are removed. This process prevents operational problems during drilling operations, improves drilling efficiency, and increases the lifespan of the equipment used.One company leading the charge in producing efficient Drilling Mud Desilters is a pioneer in engineering solutions. With over ten years of industry experience in providing drilling equipment and services, their commitment to excellence is evident in their outstanding product design and reliable customer service. The company has designed a range of Desilters, each tailored to solve specific customer challenges, and with the capacity to handle a wide range of drilling mud.Some of the benefits of using the Drilling Mud Desilter include improved efficiency, reduced downtime, reduced operating costs and increased lifespan for drilling equipment. This equipment is also critical in mitigating environmental challenges, limiting pollution, and ensuring a healthy, safe working environment for the workforce.The company has established a reputation for providing top-quality products and services, and this is no different for their line of Drilling Mud Desilters. The equipment is designed for durability, reliability, and efficiency while remaining affordable and eco-friendly. The equipment is made from high-quality materials that are built to withstand the harsh conditions of drilling operations, ensuring a long lifespan with minimal maintenance.This company's Drilling Mud Desilter is also user-friendly, easy to operate, and provides quick results. Their products are built with state-of-the-art technology, designed to meet the needs and demands of today's drilling industry. Additionally, the company provides exceptional customer support, ensuring that any concerns are addressed promptly and satisfactorily.In conclusion, Drilling Mud Desilters are essential equipment that no drilling operation can function without. They are imperative in ensuring operational cost saving, improved efficiency, and a sustainable solution to drilling-related environmental challenges. Thus, investing in reliable, durable, and cost-effective Drilling Mud Desilters, such as those offered by this company, can set the pace for continued success in drilling operations.

Essential Software Solutions and Technology Advancements for Effective Exploration Decision-Making

Exploring for minerals and metals is a complex, costly and time-consuming process. However, technology advancements have significantly changed the exploration industry over the past decade by providing innovative solutions that enhance exploration efficiencies. From remote sensing to geophysical surveys, cutting-edge technologies have emerged to increase accuracy and reduce the risks associated with mineral exploration. One aspect of exploration that has benefited from advances in technology is drill cuttings management.Drill cuttings management is a critical aspect of any mining exploration program. It involves collecting and analyzing the rock fragments or cuttings produced during drilling operations. These cuttings can be analyzed to provide essential geological information such as the mineralogy, rock type, and structure of the underlying deposit. Information from drill cuttings is used by geologists and mining engineers to make informed decisions regarding the next drilling location, prioritize targets, and guide further exploration.In the past, the process of managing drill cuttings was time-consuming and human-intensive, which resulted in delays in decision-making and high exploration costs. Nowadays, however, due to advances in digital technologies, the process has become more efficient and cost-effective.One of the leading solutions to drill cuttings management is remote sensing, which relies on the use of unmanned aerial vehicles (UAVs) to capture high-resolution images of the drilled area. The images are then analyzed using machine learning algorithms, which can accurately identify and interpret geological features, automate data processing, and improve the accuracy of the exploration data.Another technology that has transformed drill cuttings management is the use of real-time data analytics. Instead of waiting for samples to be analyzed in a laboratory, real-time data analytics can provide information on the properties of the material being drilled. This technology has the potential to be a game-changer in the exploration industry, improving the efficiency of the exploration program by providing instant feedback to exploration teams while drilling is still in progress.The use of mobile apps is another technology that has revolutionized the management of drill cuttings. Exploration teams can use mobile apps to collect data, input geological information, and track drilling progress. The apps can also be used to upload and analyze the data, which provides an interactive platform for the exploration team to collaborate. The use of mobile apps promotes critical decision-making in real-time, thus reducing the risks associated with mineral exploration.In conclusion, the exploration industry has benefited greatly from technological advancements in drill cuttings management. The use of UAVs, real-time data analytics, mobile apps and machine learning algorithms offer a more efficient and cost-effective approach to exploration. As the exploration industry continues to evolve, it is expected that we will see further advances in drill cuttings management, which will continue to drive efficiencies in the exploration process.