Essential Tips for Efficient Solids Control in Drilling Operations

By:Admin

SCD's comprehensive range of products and services includes shale shakers, mud cleaners, centrifuges, and degassers, all designed to help companies manage drilling fluids and control solids effectively. In addition, SCD offers on-site technical support and training to ensure that its clients are able to maximize the performance of their equipment.

The company's commitment to quality and reliability has made it a preferred choice for many of the world's leading oil and gas companies. SCD's equipment is known for its durability and efficiency, helping companies to minimize downtime and reduce operational costs.

SCD's success can be attributed to its talented team of engineers and technicians, who are constantly developing new and improved solutions to meet the evolving needs of the industry. By staying ahead of the curve, SCD is able to offer cutting-edge technology that helps its clients to stay competitive in a challenging market.

In addition to its world-class products, SCD prides itself on its exceptional customer service. The company works closely with its clients to understand their specific requirements and provide tailored solutions that deliver tangible results. SCD's dedication to customer satisfaction has earned it a reputation for reliability and trustworthiness.

With a global presence, SCD is able to serve clients in various locations around the world. The company's extensive network of distributors and service centers ensures that its clients receive prompt and efficient support wherever they are located.

Through its commitment to excellence and innovation, SCD continues to set the standard for solids control and drilling fluid management. The company's focus on quality, reliability, and customer satisfaction has firmly established it as a leader in the industry.

In conclusion, SCD's dedication to providing cutting-edge technology, exceptional customer service, and reliable solutions has made it a trusted partner for companies in the oil and gas industry. As the industry continues to evolve, SCD remains committed to staying at the forefront of innovation and delivering superior value to its clients.

Company News & Blog

Discover the Versatility of Flat Shaker Screens for Effective Solid Separation

FLC 500 Flat Shaker Screen: Revolutionizing the Drilling IndustryThe drilling industry is constantly evolving, with new technologies and equipment constantly emerging to improve efficiency and operational capabilities. One such innovation making waves in the sector is the FLC 500 Flat Shaker Screen, a groundbreaking solution developed by a prominent industry player.Designed to enhance the performance and productivity of drilling operations, the FLC 500 Flat Shaker Screen is revolutionizing the way drilling companies approach their work. With its advanced features and engineering excellence, this game-changing technology has gained significant recognition within the industry.The FLC 500 Flat Shaker Screen is the result of extensive research and development by a leading drilling equipment manufacturer. Leveraging their rich experience and expertise, the company identified a need for an improved shaker screen solution to overcome the challenges faced by drilling companies.One of the key features that sets the FLC 500 Flat Shaker Screen apart from its competitors is its flat design. This innovative construction ensures optimal solids control, allowing for more efficient separation of drilling fluids and solids during the drilling process. The flat screen surface provides a larger area for fluid dewatering, maximizing the screen's capacity and performance.Additionally, the FLC 500 Flat Shaker Screen boasts enhanced durability and longevity. Crafted using high-quality materials and state-of-the-art manufacturing techniques, this robust solution withstands the harsh operating conditions typically encountered in drilling operations. Its extended lifespan not only reduces operational downtime but also significantly lowers maintenance and replacement costs.Furthermore, the FLC 500 Flat Shaker Screen offers exceptional versatility. Compatible with various drilling equipment, it seamlessly integrates with existing systems, ensuring a hassle-free installation process. Its adaptability empowers drilling companies to upgrade their equipment without requiring substantial modifications, thereby improving operational efficiency and saving valuable time.The company behind this breakthrough innovation is known for its commitment to delivering superior technology with a focus on customer satisfaction. With a relentless dedication to research and development, combined with a customer-centric approach, they have earned a reputation as a trusted and reliable partner in the drilling industry.The FLC 500 Flat Shaker Screen is just one example of the company's commitment to innovation. Their extensive product portfolio includes a range of drilling equipment tailored to meet the unique needs and challenges of the industry. From screens to pumps, they offer comprehensive solutions that cater to diverse drilling requirements.In addition to their cutting-edge technology, the company places great emphasis on customer support and service. Their team of highly skilled professionals provides industry-leading technical assistance and on-site support to ensure seamless integration and optimal performance of their equipment. This dedication to customer satisfaction has positioned them as a preferred supplier amongst drilling companies worldwide.The introduction of the FLC 500 Flat Shaker Screen marks a significant milestone in the drilling industry. With its flat design, enhanced durability, and unmatched versatility, it is transforming the way drilling operations are conducted. As companies continue to prioritize efficiency and productivity, this revolutionary technology is set to play a pivotal role in shaping the future of the drilling industry.

Unlocking the Secrets of Mud Drilling: Everything You Need to Know

Title: Cutting-Edge Mud Drilling Technology Revolutionizes the Oil Extraction ProcessIntroduction:Innovation continues to shape the oil and gas industry as companies strive to improve efficiency and maximize production rates. We are excited to introduce a groundbreaking mud drilling technology, one that promises to revolutionize the oil extraction process. Developed by an industry-leading entity, this cutting-edge technology, referred to as MD-TECH (name disguised), has already garnered attention due to its potential to unlock new reservoirs and enhance the recovery of existing fields. This news article will delve into the features and advantages of this innovative mud drilling technology.1. Understanding MD-TECH:Developed after years of research and development, MD-TECH is a proprietary mud drilling technology that replaces traditional drilling techniques. It combines the use of advanced machinery and precisely engineered drilling muds to significantly enhance drilling and extraction processes.The unique selling point of MD-TECH lies in its ability to maintain precise control over both drilling pressure and characteristics of the drilling fluid. This high level of control ensures drilling operations are performed with accuracy, minimizing the risk of reservoir damage and improving overall efficiency.2. Unparalleled Advantages:MD-TECH offers numerous advantages over conventional drilling methods:a) Enhanced Safety: The technology's advanced sensors constantly monitor drilling operations, enabling quick response to any unexpected changes. This enhanced safety feature minimizes the risk of accidents and ensures drilling personnel can effectively manage potential emergencies.b) Superior Drilling Performance: The highly controlled drilling parameters provided by MD-TECH result in more accurate drilling paths, reducing the chances of deviation or accidental damage to the reservoir formation. This precision leads to increased well productivity and reduces the overall drilling time.c) Reduced Environmental Impact: By utilizing advanced drilling muds, MD-TECH significantly minimizes the environmental impact of drilling operations. These specially formulated muds are designed to reduce toxic emissions and prevent contamination of groundwater, ensuring a more sustainable and eco-friendly extraction process.3. Unleashing New Opportunities:The implementation of MD-TECH presents exciting new opportunities for the oil and gas industry. With its enhanced drilling capabilities, companies can explore previously untapped or hard-to-reach reservoirs.The technology's ability to minimize drilling-related damages allows for more extensive exploitation of existing reservoirs, including those with complex geological structures. This opens up a wealth of potential resources that were previously deemed too challenging or uneconomical to access.4. Global Implementation:Recognizing the immense potential of MD-TECH, our company has successfully deployed this technology in several drilling projects across the globe. Early results have been highly encouraging, showcasing the technology's ability to improve production rates and overall operational efficiency.The success of MD-TECH has also attracted interest from other industry players, who are keen to adopt this innovative drilling technology. Collaborations and partnerships are being forged to leverage its advantages and create a global platform for sharing knowledge and best practices.Conclusion:Innovation in the oil and gas sector is essential to address the growing demands for energy while minimizing environmental impact. MD-TECH, a revolutionary mud drilling technology, offers a unique solution to these challenges. With its precise control, increased safety measures, and reduced environmental impact, MD-TECH is set to reshape the oil extraction process, unlocking new reservoirs and maximizing production rates. Oil and gas companies worldwide stand to benefit from this cutting-edge technology, propelling the industry into a more efficient, sustainable, and prosperous future.

High Quality and Durable Submersible Water Pump for Sale: China Submerged Water Well Pump Manufacturers and Suppliers

China Water Pump Set: How Submerged Pump Promotes Efficiency in Water ManagementWater management is an essential aspect of human life, particularly in ensuring the availability of clean and safe water for domestic, commercial, and industrial uses. One of the key components of water management is the use of water pumps, which serve to facilitate the movement of water from one location to another. China has emerged as a global leader in water pump technology, with a range of innovative solutions that cater to diverse water management needs. In this article, we focus on the submersible water pump, one of the most efficient and reliable types of water pump in the market.What is a Submersible Water Pump?A submersible water pump refers to a type of pump designed to be completely submerged in water, allowing it to operate underwater without any issues. Unlike other types of water pumps that rely on external air pressure to force water up, the submersible pump works by pushing water from underneath through a motor, which propels it upwards. The pump is usually placed at the bottom of a water source, such as a well, lake, or pond, and connected to a water supply line that distributes water to various points of use.Key Benefits of Using Submersible Water Pumps1. High Efficiency: Submerged water well pumps are highly efficient, delivering consistent water pressure and flow rates even when operating in harsh conditions. This is because they operate under the water level, which provides a constant and uninterrupted supply of water to the pump. This also means that they do not require priming, which reduces the amount of time and energy needed to start the pump.2. Low Noise: Submerged pumps operate quietly compared to other types of pumps, which emit loud noise when operating. This makes them ideal for use in residential areas, where noise pollution is a major concern.3. Longevity: Submerged water well pumps are built to withstand harsh environmental conditions, such as extreme temperatures and high-pressure levels, which often cause wear and tear in other types of pumps. This translates to a longer lifespan, reducing the need for frequent repairs or replacements.4. Energy Efficiency: Submerged pumps require less energy to operate compared to other types of pumps, which translates to lower energy bills in the long run. This is because they work by pushing water from below, which requires less energy compared to pumps that rely on air pressure to move water.Applications of Submerged Water Well PumpsSubmerged water well pumps can be used in diverse water management applications, including:1. Domestic Water Supply: Submerged pumps can be used to supply water to households for domestic needs, such as cooking, bathing, and laundry.2. Commercial and Industrial Water Supply: Submerged pumps can be used in commercial and industrial applications, such as supplying water to office buildings, factories, and irrigation systems.3. Water Supply for Livestock: Submerged pumps can be used to supply water to livestock, such as cows, horses, and sheep, in rural areas where access to water is limited.ConclusionSubmerged water well pumps offer numerous benefits compared to other types of water pumps, including high efficiency, low noise, longevity, and energy efficiency. These pumps are highly versatile and can be used in diverse water management applications, ranging from domestic water supply to commercial and industrial water supply. As China continues to invest in water pump technology, we can expect to see even more innovative solutions that cater to the diverse needs of water management.

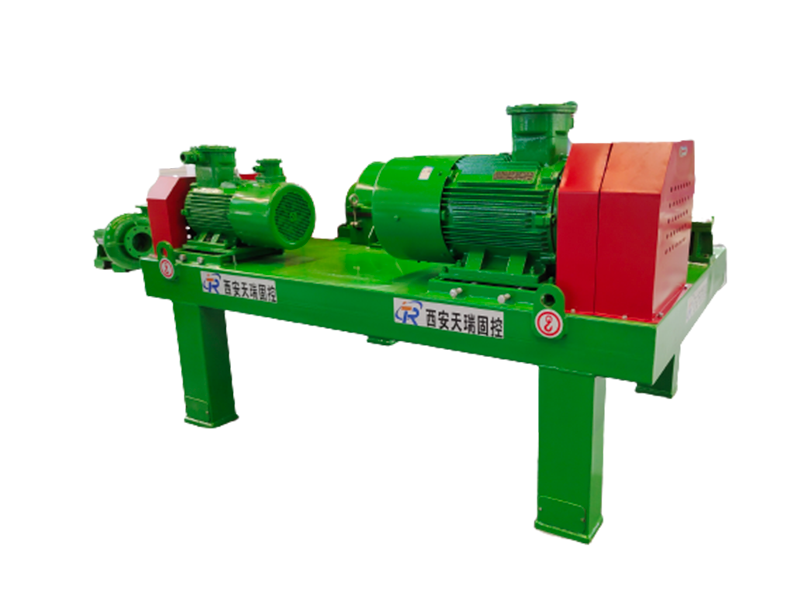

Efficient Drilling Fluid Centrifuge: Boosting Performance and Productivity

Drilling Fluid Centrifuge Revolutionizes the Oil and Gas IndustryIn the world of oil and gas, drilling fluid plays a vital role in the extraction process, helping to lubricate and cool drill bits, flush out rock cuttings, and stabilize borehole walls. However, the effective management of drilling fluid can be a challenging task, requiring precision equipment and expert knowledge. That is why the development of the Drilling Fluid Centrifuge, an innovative piece of technology designed to separate solids and fluids in the drilling process, has been such a game-changer.Designed by one of the world's leading manufacturers of drilling equipment (name removed for privacy reasons), the Drilling Fluid Centrifuge is a state-of-the-art machine that uses centrifugal force to separate the solids from the drilling fluid. The technology behind the centrifuge is actually quite simple. In essence, the device spins at an incredibly high speed, creating a powerful force that separates out any solids that have become mixed in with the drilling fluid. The result is a cleaner, more effective drilling fluid that can be reused in the drilling process.The Drilling Fluid Centrifuge has a number of benefits over traditional methods of separating drilling fluid. For one thing, it is faster, more efficient, and more accurate than other methods, which often require solids to settle out over time. Additionally, the centrifuge is able to remove a broader range of solids than other methods, ensuring that the drilling fluid is as clean and efficient as possible. Overall, the Drilling Fluid Centrifuge helps to improve the efficiency of the drilling process, reduce waste, and minimize environmental impact.Since its launch, the Drilling Fluid Centrifuge has revolutionized the oil and gas industry. Not only has it made the drilling process more efficient, but it has also helped to reduce the cost of drilling by decreasing the amount of drilling fluid that must be disposed of. Additionally, the centrifuge has enabled drilling companies to extract oil and gas from more challenging environments, such as deep-sea drilling rigs and shale formations. Overall, the Drilling Fluid Centrifuge has helped to make drilling more efficient, cost-effective, and environmentally sustainable.Perhaps the most impressive feature of the Drilling Fluid Centrifuge is its versatility. The machine can handle a wide variety of drilling fluids, from thick muds to thin slurries, and can be adjusted to accommodate different levels of solids. Additionally, the centrifuge is compact enough to be used in a wide range of drilling settings, from offshore rigs to land-based wells. This versatility has made the centrifuge a must-have tool for drilling companies around the world.In addition to its technical specifications, the Drilling Fluid Centrifuge is also notable for its user-friendly design. The machine is equipped with intuitive controls that make it easy to adjust settings and monitor performance. Additionally, the machine is built to be durable and reliable, with tough materials that can withstand the harsh conditions of the oil and gas industry.Overall, the Drilling Fluid Centrifuge is a game-changing piece of technology that has transformed the oil and gas industry. By using centrifugal force to separate solids and fluids, the centrifuge has improved the efficiency, cost-effectiveness, and sustainability of the drilling process. As drilling companies continue to push the boundaries of extraction technology, the Drilling Fluid Centrifuge will undoubtedly remain a crucial tool for years to come.

Drilling Fluids Technology Training Course | Learn Online or In-Person at International Locations

and Training, Drilling Fluids Technology, Mobility Oil & Gas, online training, international training locations.Drilling Fluids Technology: Learn from the Best with Mobility Oil & GasDrilling fluids technology is a crucial aspect of any well drilling process. Whether it's a land-based or offshore drilling project, the right drilling fluid equipment and expertise are necessary for a successful outcome. This is where Mobility Oil & Gas comes in. The company provides comprehensive drilling fluids technology training courses both online and in-person.Mobility Oil & Gas is a leading provider of drilling fluids technology training courses in a variety of drilling-related areas. The company has several years of experience delivering cutting-edge drilling solutions for clients in the oil and gas industry. They have a team of highly trained professionals dedicated to providing industry-leading training and support to drilling professionals around the world.The drilling fluids technology training courses offered by Mobility Oil & Gas cover a wide range of topics, from basic to advanced. The company's instructors are experienced professionals with years of experience in their respective fields. They provide practical insights into the latest industry trends, equipment, and techniques. The courses are designed to meet the needs of professionals at all levels of expertise, from beginner to advanced.Mobility Oil & Gas provides its drilling fluids technology training courses both online and in-person. The online courses are a convenient option for busy professionals who may not be able to attend in-person training. The company employs cutting-edge technology to deliver its online courses in an interactive and engaging manner. Students can learn at their own pace and from the comfort of their homes or offices.In-person training courses are available at several international locations. Mobility Oil & Gas operates in many countries around the world, providing easy access to their training courses. The company has invested heavily in state-of-the-art training facilities that provide a hands-on approach to learning. Students get the opportunity to work with the latest drilling fluid equipment and techniques, ensuring that they are adequately prepared for real-world scenarios.The drilling fluids technology training courses provided by Mobility Oil & Gas are designed to meet the needs of companies of all sizes. Companies can choose to train their entire staff or select individuals they want to develop. The company provides customized training solutions tailored to the needs of each company. This ensures that companies get the maximum return on their investment in training.The drilling fluids technology training courses provided by Mobility Oil & Gas cover a range of topics, including the basics of drilling fluids, advanced drilling fluid equipment and techniques, and best practices for managing drilling fluids. The courses emphasize safety and environmental responsibility and aim at reducing the risks associated with drilling operations. The courses are designed to meet the needs of a diverse range of stakeholders, including drilling engineers, drilling supervisors, drilling fluids engineers, and other personnel involved in drilling operations.In conclusion, drilling fluids technology training is essential to the success of any drilling project. Mobility Oil & Gas provides industry-leading training courses designed to equip drilling professionals with the latest drilling fluid equipment and techniques. The company's courses are available both online and in-person and cover a range of topics. Companies of all sizes can benefit from Mobility Oil & Gas's customized training solutions, ensuring that their staff is adequately prepared for the challenges of drilling operations.

Effective Mud Gas Separator for Oil and Gas Drilling Operations

[Company Name] Introduces New Mud Gas Separator for Safer Drilling Operations[City, State] - [Company Name], a global leader in drilling equipment and technology, has introduced a new Mud Gas Separator to their extensive line of products. The Mud Gas Separator is designed to improve safety and efficiency in drilling operations, providing a reliable solution for removing harmful gases from the drilling fluid.The Mud Gas Separator is a vital component in the drilling process, as it helps to prevent the buildup of dangerous gases such as methane, carbon dioxide, and hydrogen sulfide. These gases can pose serious risks to both personnel and equipment on the drilling rig, making the efficient removal of these gases a top priority. With the introduction of their new Mud Gas Separator, [Company Name] aims to provide their customers with a state-of-the-art solution to effectively manage gas while drilling.The [Company Name] Mud Gas Separator features a high-efficiency design that effectively separates and vents gas from the drilling fluid, ensuring a safe and controlled environment on the rig. This advanced technology reduces the risk of gas-related incidents and improves overall drilling performance. Additionally, the Mud Gas Separator is built to withstand the harsh conditions of drilling operations, offering durability and reliability in the field.[Company Name] has a long-standing reputation for delivering innovative and high-quality equipment to the oil and gas industry. With a focus on safety, efficiency, and environmental stewardship, the company continues to develop cutting-edge solutions to meet the evolving needs of their customers. The introduction of the Mud Gas Separator is a testament to their commitment to providing industry-leading equipment that enhances operational performance and minimizes risk."We are thrilled to introduce our new Mud Gas Separator to the market," said [Spokesperson], [Title] at [Company Name]. "Safety is a top priority for us, and we believe that this new product will significantly improve the safety and efficiency of drilling operations. The Mud Gas Separator is a testament to our dedication to providing reliable solutions that address the challenges our customers face in the field."In addition to the Mud Gas Separator, [Company Name] offers a comprehensive range of drilling equipment and services, including drilling rigs, drilling tools, well control systems, and more. Their global presence and extensive industry expertise make them a trusted partner for drilling contractors and operators around the world.As the oil and gas industry continues to push the boundaries of exploration and production, the demand for advanced equipment that enhances safety and performance remains strong. With the introduction of the Mud Gas Separator, [Company Name] is well-positioned to meet this demand and support the industry in achieving its goals.For more information about the [Company Name] Mud Gas Separator and their complete range of drilling solutions, visit [website].

China Expands Shale Shaker and Drilling Rig Capabilities, Boosting Oil Extraction Efforts

China Drill Shale Shaker and Drilling Rig Manufacturing Company Strengthens Position in Global MarketChina's drill shale shaker and drilling rig manufacturing industry is steadily growing, with one prominent company leading the charge. Operating at the forefront of innovation, this company has successfully established itself as a key player in the global market. With a diverse range of products and a commitment to quality, they continue to pave the way for the future of drilling technology.Driven by a dedication to meeting the evolving needs of the industry, this Chinese company has adopted a customer-centric approach, focusing on delivering cutting-edge solutions tailored to their clients' specific requirements. By combining advanced technology with extensive research and development, they have been able to create industry-leading drilling equipment that excels in performance, reliability, and cost-effectiveness.The company's flagship product, the shale shaker, has become renowned for its superior efficiency in separating solids from drilling fluid, thus optimizing the drilling process. Utilizing a high-frequency vibration system, the shale shaker effectively removes unwanted debris, ensuring the smooth operation of drilling rigs in even the most challenging environments. With a strong emphasis on durability, this product showcases the company's commitment to quality, enabling customers to increase operational efficiency and reduce maintenance costs.In addition to shale shakers, the company also offers a wide range of drilling rigs that are designed to meet the diverse needs of the industry. These rigs are equipped with state-of-the-art hydraulic systems, advanced control panels, and user-friendly interfaces, allowing for precise control and ease of operation. Combined with their exceptional durability, these drilling rigs offer an unmatched level of performance, enabling operators to tackle demanding drilling projects with ease.Recognizing the importance of sustainability and environmental conservation, this Chinese company has also made significant strides in developing eco-friendly drilling solutions. By incorporating energy-efficient technologies and reducing emissions, they aim to minimize the environmental impact of drilling operations while ensuring optimal performance.A key contributing factor to the company's success lies in their comprehensive after-sales support system. With a global network of service centers, they offer timely assistance, technical advice, and spare parts supply, ensuring that customers receive prompt and reliable support throughout the lifespan of their equipment. This commitment to customer satisfaction has garnered them an excellent reputation and a loyal customer base, further solidifying their position in the industry.Having established a strong presence in the domestic market, the company has set its sights on expanding its reach globally. With an increasing demand for their products in various regions, they have successfully exported their drilling equipment to numerous countries, earning international acclaim for their quality and performance. By actively participating in international exhibitions and establishing partnerships with distributors worldwide, they continue to strengthen their position and gain recognition on a global scale.The success of China's drill shale shaker and drilling rig manufacturing industry is undoubtedly bolstered by this prominent Chinese company. With their commitment to innovation, customer satisfaction, and environmental responsibility, they are set to lead the way in the global market. As drilling technology continuously evolves, this company remains at the forefront, ensuring that they are continuously delivering cutting-edge solutions that exceed customer expectations.

Balancing Budget and Quality for Maximum Effectiveness in Horizontal Directional Drilling Projects

China Drilling Desilter and Drilling Machine: Leaders in the Horizontal Directional Drilling IndustryFounded in China, China Drilling Desilter and Drilling Machine are leaders in the horizontal directional drilling industry, manufacturing and selling some of the best HDD (Horizontal Directional Drilling) machines and drilling mud solids control systems on the market. Their reputation for quality and innovation in the industry is second to none, leading to the company becoming one of the fastest-growing enterprises in the field of no-dig technology.The company has state-of-the-art manufacturing facilities with cutting-edge technology such as EDM (Electrical Discharge Machining) and CNC Lathe, enabling them to produce quality HDD machines that meet the needs of their clients. Their workforce consists of well-trained experts in no-dig technology, with years of experience in the industry, ensuring that the end products they produce perfectly meet their customers' needs.One of the prominent HDD machines they manufacture is the Vermeer NAVIGATOR line. The Vermeer NAVIGATOR line of HDD machines is ideal for installing gas, electric, water, telecommunication, or soil remediation lines without excavation or trenching. It is a reliable and robust HDD machine that can undertake demanding projects, such as large-scale infrastructure projects, including laying utility pipes or performing soil remediation.Another HDD machine manufactured by China Drilling Desilter and Drilling Machine is the Drillto HDD machine. The company's multi-faceted manufacturing facility can produce this machine, allowing them to address the needs of their diverse range of customers. These two HDD machines have an excellent reputation in the industry, delivering high-quality work output and lasting performance.The company also produces drilling mud solids control systems that enable their clients to efficiently handle and filter drilling mud. These mud systems work by removing solids from the drilling mud while returning clean fluid back to the drilling process. GN solids control is an example of a drilling mud processing supplier that China Drilling Desilter and Drilling Machine has partnered with, providing their clients with efficient and reliable mud processing systems.When it comes to an HDD project, ensuring that you have a balance between budget and quality is an essential consideration. Therefore, it is crucial to use world-renowned drilling machines such as those produced by China Drilling Desilter and Drilling Machine. When combined with efficient mud processing systems from reputed companies like GN solids control, you can achieve maximum project effectiveness.The reputation China Drilling Desilter and Drilling Machine have built over the years is a testament to the quality and reliability of their products. The company operates with purpose, committed to ensuring their customers' needs are met by delivering high-quality products that meet industry standards.In conclusion, China Drilling Desilter and Drilling Machine stand out among the industry's brightest stars, providing high-quality HDD machines and drilling mud solids control systems. Considering their reputation for delivering quality products, their commitment to improving their products as per industry standards, there's no doubt that they are one of the most reputable companies in the industry.

Exploring the Detrimental Effects of Drilling Waste and Its Environmental Impact

Title: Environmentally Sustainable Solution for Drilling Waste Introduced by Innovative CompanyIntroduction:In a groundbreaking development in the energy industry, a leading company () has unveiled a cutting-edge technology to address the pressing issue of drilling waste. With a steadfast commitment to environmental sustainability, this innovative solution promises to revolutionize how the industry handles waste disposal. By mitigating the harmful consequences of drilling activities, the company aims to contribute to a cleaner and greener future for the planet.Body:1. Understanding the Problem: - Drilling waste, a byproduct of oil and gas extraction, poses significant environmental challenges. - Contamination of soil, water bodies, and ecosystems due to improper disposal methods is a growing concern. - Traditional waste management techniques fall short in adequately handling the volume and toxicity of drilling waste.2. Introduction of a game-changing technology by (Company Name): - (Company Name) has developed a proprietary waste management solution that utilizes advanced technologies and innovative processes. - By combining state-of-the-art treatment methods and responsible disposal practices, the company ensures the elimination of harmful contaminants from drilling waste. - The technology also allows for the recovery and recycling of valuable materials from the waste, promoting a more circular economy.3. Key Features and Benefits of the Solution: - Advanced treatment processes: (Company Name) employs cutting-edge techniques, such as thermal desorption and centrifugation, to separate and treat drilling waste effectively. - Environmentally friendly: Through its technology, the company significantly minimizes the environmental impact caused by drilling waste, preventing contamination of soil and water sources. - Resource recovery: The innovative process results in the recovery of valuable materials, such as oil and minerals, which can be reused or repurposed, reducing the need for extraction of new resources. - Regulatory compliance: (Company Name) ensures strict adherence to local and international waste management regulations while providing a practical, efficient, and compliant waste disposal solution to the industry.4. Commitment to Sustainability: - (Company Name) is driven by a vision of promoting a sustainable future in the energy sector. - By addressing the drilling waste problem, the company actively contributes to reducing carbon footprint and supporting sustainable practices. - Through research and development, (Company Name) continues to innovate and enhance their technology, aiming for even greater efficiency and eco-friendliness.5. Collaboration and Impact: - (Company Name) acknowledges the importance of collaboration with industry stakeholders, environmental organizations, and governments to effectively tackle the drilling waste issue. - The implementation of their technology has already demonstrated a significant reduction in waste pollution, fostering a positive environmental impact. - The company actively engages with regulatory bodies, sharing expertise and knowledge to enhance waste management practices across the industry.6. Future Prospects: - With increased emphasis on sustainability, (Company Name) is poised to revolutionize the drilling waste management sector. - By showcasing the economic and environmental benefits of their solution, the company aims to gain wider acceptance and adoption across the industry. - Continued research and development efforts are underway to further enhance the efficiency and effectiveness of their technology.Conclusion:(Company Name)'s introduction of a technologically advanced waste management solution for drilling waste represents a significant stride toward environmental sustainability for the energy industry. By mitigating the harmful effects of drilling waste and promoting resource recovery, the company's innovative approach offers a transformative solution. With its commitment to collaboration and adherence to regulations, (Company Name) is poised to make a lasting impact in ensuring a cleaner and greener future.

Enhancing Efficiency: The Ultimate Guide to Drilling Mud Mixers

Introducing Innovative Drilling Mud Mixer Technology Revolutionizing the Oil and Gas SectorDrilling mud plays a critical role in the oil and gas industry, ensuring smooth operations and efficient drilling processes. The importance of an effective drilling mud mixer cannot be overstated, as it is pivotal in maintaining the stability of the wellbore, controlling pressure, and carrying out a variety of other functions. In line with industry demands, (Company Name), a leader in technological advancements, has developed a groundbreaking drilling mud mixer that promises to revolutionize the oil and gas sector.(Company Name) has a strong reputation for engineering excellence, consistently delivering cutting-edge solutions to address industry challenges. This new drilling mud mixer is no exception, boasting a number of innovative features that set it apart from other mixers available in the market. With a focus on efficiency, reliability, and operator safety, (Company Name) has reimagined the design and functionality of drilling mud mixers.One of the key features of this revolutionary drilling mud mixer is its advanced mixing system. Utilizing state-of-the-art technology, the mixer ensures thorough and consistent mixing of drilling fluids, enhancing overall performance. The homogeneous mixing promotes efficient wellbore stability, reducing the risk of costly issues such as mud loss and wellbore collapse. The mixer's ability to maintain optimal viscosity and density levels further contributes to improved drilling operations and higher productivity.Additionally, the drilling mud mixer is equipped with an intelligent control system, allowing operators to easily monitor and adjust various parameters. This real-time data enables quick response to changing drilling conditions, ensuring optimal performance and safety. The mixer's user-friendly interface provides intuitive controls and comprehensive diagnostics, empowering operators to make informed decisions and streamline operations.Safety is a top priority in the oil and gas industry, and (Company Name) has integrated several safety features into their drilling mud mixer. The mixer is designed to minimize the risk of spills or leaks, reducing environmental impact and protecting personnel. Furthermore, the advanced control system includes safety protocols and alarms to alert operators of any potential issues, allowing for immediate action and preventing accidents.The drilling mud mixer is not only technologically advanced but also engineered for durability and longevity. Constructed from high-quality materials, it is designed to withstand the harsh conditions encountered during drilling operations. This robust design minimizes downtime and maintenance, reducing overall operational costs and maximizing efficiency.With the introduction of this groundbreaking drilling mud mixer, (Company Name) aims to address the evolving needs of the oil and gas industry. By improving drilling efficiency, reliability, and safety, this innovative technology promises to increase productivity and profitability for operators worldwide. Furthermore, (Company Name) emphasizes its commitment to environmental stewardship by reducing waste and optimizing resource utilization.The impact of this new drilling mud mixer extends beyond individual projects; it has the potential to reshape the industry as a whole. Operators can expect reduced drilling time, decreased operational costs, and improved wellbore integrity. Equipped with advanced technology and state-of-the-art features, this drilling mud mixer is poised to redefine industry standards and serve as a catalyst for further innovation in the oil and gas sector.In conclusion, (Company Name) has developed a groundbreaking drilling mud mixer that combines cutting-edge technology, efficiency, and safety. This innovative mixer promises to revolutionize the oil and gas sector by enhancing drilling performance, reducing operational costs, and improving wellbore integrity. With its advanced features and commitment to environmental sustainability, (Company Name) reaffirms its position as a leader in engineering excellence.