Ultimate Guide to PMD Screens: What You Need to Know

By:Admin

The Hyperpool PMD Screen is a cutting-edge platform that leverages the power of data analytics and artificial intelligence to streamline the recruitment process. This innovative tool is designed to help companies identify the best candidates for their job openings, by analyzing a wide range of data points to evaluate the suitability of each applicant. By harnessing the power of machine learning and predictive modeling, the Hyperpool PMD Screen can provide valuable insights into a candidate’s skills, experience, and potential fit within an organization.

The Hyperpool PMD Screen is a game-changer for talent acquisition and management, as it allows companies to make smarter, data-driven decisions when it comes to hiring. By leveraging the power of data and analytics, organizations can gain a deeper understanding of their candidate pool, and make more informed decisions that align with their business objectives. This cutting-edge platform is designed to help companies identify the best talent for their needs, and streamline the recruitment process to save time and resources.

The Hyperpool PMD Screen is a scalable solution that can be tailored to meet the unique needs of any organization. Whether a company is looking to fill a single position or manage a large-scale recruitment campaign, this platform can provide the insights and support needed to make smarter hiring decisions. By leveraging the power of data and analytics, the Hyperpool PMD Screen can help companies identify the best candidates for their job openings, and ensure that they are making the most of their talent acquisition efforts.

The Hyperpool PMD Screen is just one of the latest offerings from {}, a company that is dedicated to providing innovative workforce solutions and services to help companies thrive in today’s competitive business environment. With a strong focus on technology and innovation, {} is committed to helping companies identify, attract, and retain top talent, and ensure that they have the resources needed to succeed. By leveraging the power of data and analytics, the company is paving the way for a new era of talent acquisition and management, and helping organizations make smarter, data-driven decisions when it comes to hiring.

In addition to the Hyperpool PMD Screen, {} offers a wide range of other workforce solutions and services to help companies address their talent acquisition and management needs. From recruitment process outsourcing and talent management to workforce consulting and employer branding, the company provides a full suite of services to help companies attract, retain, and develop their talent. By combining cutting-edge technology with deep industry expertise, {} is dedicated to helping companies thrive in today’s rapidly changing business landscape.

The launch of the Hyperpool PMD Screen represents a significant milestone for {}, as the company continues to innovate and lead the way in workforce solutions and services. With its advanced screening and assessment capabilities, this new offering is poised to revolutionize the talent acquisition and management industry, and help companies make smarter, data-driven decisions when it comes to hiring. As organizations continue to face increasing competition for top talent, the Hyperpool PMD Screen is a powerful tool that can help companies gain a competitive edge and drive success in today’s dynamic business environment.

Company News & Blog

Effective Mud Cleaning Equipment for Efficient Operations

Mud Cleaning Equipment for Oil and Gas IndustryThe oil and gas industry is one of the most important sectors in the world, providing fuel and energy to power the global economy. However, the process of extracting oil and gas from the earth can be a messy and challenging endeavor, often resulting in the production of large amounts of drilling mud, a mixture of water, clay, and various chemicals used to aid in the drilling process. This drilling mud must be properly treated and disposed of to comply with environmental regulations and to ensure the efficiency of drilling operations. This is where mud cleaning equipment plays a crucial role.One of the leading providers of mud cleaning equipment is a global company that has been at the forefront of the oil and gas industry for over two decades. With a focus on innovation and sustainability, the company has developed state-of-the-art mud cleaning equipment that is designed to efficiently separate solids from drilling mud, allowing for the recycling and reuse of the liquid components. This not only reduces the environmental impact of drilling operations but also helps to minimize waste and save on costs.The company's mud cleaning equipment is designed to handle a wide range of drilling mud types and can be customized to meet the specific needs of different drilling environments. Whether it's a small onshore drilling operation or a large offshore rig, the company's mud cleaning equipment is up to the task, providing reliable and efficient performance in even the most challenging conditions.One of the key features of the company's mud cleaning equipment is its advanced filtration system, which is capable of removing a wide range of solid particles from the drilling mud, including fine sands, silt, and clay. This helps to ensure that the recycled mud is of high quality and can be reused in the drilling process, reducing the need for fresh water and minimizing the overall environmental impact of drilling operations.In addition to its cutting-edge filtration technology, the company's mud cleaning equipment is also designed to be highly efficient and easy to operate. With user-friendly controls and minimal maintenance requirements, the equipment is designed to keep downtime to a minimum, ensuring that drilling operations can continue without interruption.Furthermore, the company's commitment to sustainability extends beyond the design of its equipment. The company also offers comprehensive training and support services to help clients maximize the efficiency of their mud cleaning equipment and minimize their environmental footprint. Additionally, the company is continuously investing in research and development to improve the performance of its equipment and develop new technologies to further reduce the environmental impact of drilling operations.With a global network of offices and service centers, the company is able to provide its mud cleaning equipment and support services to clients around the world, ensuring that they can meet their environmental and operational goals regardless of their location.In conclusion, mud cleaning equipment plays a crucial role in the oil and gas industry, helping to ensure the sustainability and efficiency of drilling operations. With its advanced filtration technology, high efficiency, and commitment to sustainability, the mud cleaning equipment provided by this global company is helping to redefine the standards for environmental responsibility in the oil and gas industry. As the industry continues to evolve, the company remains committed to driving innovation and helping clients to meet their environmental and operational goals.

High Quality 240m3/h Mud Cleaning Equipment with 4" Desilter Cones and Bottom Shale Shaker - Efficient Mud Cleaning Systems

Efficient Mud Tank System for Drilling Rigs

Mud Tank System Drilling Rig: Revolutionizing the Oil and Gas IndustryThe oil and gas industry has long been reliant on drilling rigs to extract hydrocarbons from deep beneath the earth's surface. These rigs are vital in the production of crude oil and natural gas, and their efficiency and reliability directly impact the industry's productivity. One company at the forefront of revolutionizing drilling rig technology is {}, a leading provider of innovative solutions for the oil and gas sector.At the heart of their groundbreaking offerings is the Mud Tank System Drilling Rig, a technological marvel that has been hailed as a game-changer in the industry. This state-of-the-art rig is designed to maximize operational efficiency, streamline drilling processes, and enhance safety measures, ultimately leading to increased productivity and reduced downtime.The Mud Tank System Drilling Rig features a cutting-edge mud tank system that is integral to its performance. This system is designed to efficiently handle drilling waste and regulate the flow of drilling fluids, ensuring a clean and controlled environment for the drilling operation. By effectively managing mud and drilling fluids, the rig minimizes the impact on the surrounding environment and reduces the risk of operational hazards.Moreover, the Mud Tank System Drilling Rig is equipped with advanced monitoring and control systems that provide real-time data on drilling parameters. This enables operators to make quick and informed decisions, optimize drilling processes, and mitigate potential issues before they escalate. The rig's automated features and remote monitoring capabilities further enhance operational control and contribute to a safer working environment for personnel.In addition to its technological prowess, the Mud Tank System Drilling Rig is designed with versatility in mind. It can be customized to meet the specific requirements of different drilling projects, whether in onshore or offshore locations. Its modular design allows for easy transportation and assembly, making it well-suited for remote and challenging environments.This innovative drilling rig has already made a significant impact in the oil and gas industry, with numerous successful deployments and favorable feedback from operators. Its performance has been commended for its reliability, operational efficiency, and environmental stewardship. As the industry continues to adapt to evolving challenges and demands, the Mud Tank System Drilling Rig is poised to play a pivotal role in shaping the future of drilling operations.In line with this commitment to innovation and excellence, {} has established itself as a driving force in the oil and gas sector. With a rich history of delivering cutting-edge solutions and a strong focus on research and development, the company is dedicated to pushing the boundaries of technology to address the industry's evolving needs.{} has solidified its reputation as a trusted partner for oil and gas companies seeking reliable and efficient solutions. Their comprehensive portfolio of products and services spans the entire spectrum of drilling and production operations, encompassing drilling rigs, well services, and environmental solutions. Coupled with their unwavering commitment to safety and sustainability, the company has earned the trust and confidence of industry stakeholders worldwide.Looking ahead, {} remains steadfast in its pursuit of innovation and advancement. The company continues to invest in research and development, collaborating with industry partners and experts to push the boundaries of drilling technology. With a keen eye on emerging trends and challenges, {} is poised to lead the industry towards a more sustainable and efficient future.In conclusion, the Mud Tank System Drilling Rig stands as a testament to the transformative potential of technological innovation in the oil and gas industry. Through its cutting-edge design, advanced features, and versatility, this rig exemplifies the strides being made towards enhancing operational efficiency, safety, and environmental responsibility. In partnership with companies like {}, the industry is primed to embrace a new era of drilling excellence.

Discover the Latest Advancements in China's Sugar Syrup Pump and Transfer Pump Technology

China Sugar Syrup Pump and Sugar Syrup Transfer Pump: Revolutionizing the Sugar IndustryChina has long been known as one of the world's leading producers and consumers of sugar. From the traditional sweetening of beverages and desserts to the use of sugar as an essential ingredient in various industries, the demand for high-quality sugar products continues to rise. To meet this growing demand, Chinese manufacturers have taken innovative steps to develop advanced equipment for the sugar industry. Among these innovations are the China Sugar Syrup Pump and Sugar Syrup Transfer Pump, two cutting-edge products that have revolutionized the sugar production process.Manufactured by a leading company in the field of fluid handling, these pumps have already made significant contributions to the sugar industry. Their efficiency, reliability, and precision have garnered attention both domestically and internationally. Importantly, these pumps have not only improved the production capabilities of sugar manufacturers but have also brought about several positive environmental implications.Traditionally, the sugar manufacturing process involved time-consuming and labor-intensive manual procedures. Workers would manually transfer the sugar syrup from one container to another, often resulting in losses due to spillage and inaccuracies. Moreover, this method caused unnecessary physical strain on employees, jeopardizing their safety. Recognizing the need for a more efficient, accurate, and automated solution, the manufacturer designed the China Sugar Syrup Pump and Sugar Syrup Transfer Pump.These pumps are equipped with state-of-the-art technology and advanced features that ensure a smooth and automated sugar syrup transfer process. They are designed to withstand the unique characteristics of sugar syrup, which can be sticky and viscous. With their high suction power and efficient pumping abilities, the pumps minimize spillage and reduce wastage significantly. Furthermore, the pumps' precision ensures accurate measurements, eliminating errors in dosage and improving the overall quality of sugar products.Notably, besides their efficiency and reliability, the China Sugar Syrup Pump and Sugar Syrup Transfer Pump have substantial environmental benefits. By reducing wastage and enhancing accuracy, these pumps minimize the overall impact of sugar production on the environment. Additionally, the automation of the transfer process reduces the need for manual labor, consequently lowering the carbon footprint and improving worker safety. These innovative pumps represent a significant step toward sustainable sugar production practices.The company behind these groundbreaking pumps has been at the forefront of fluid handling technology for several years. With a commitment to research and development, this leading manufacturer has consistently pushed the boundaries of innovation, introducing cutting-edge solutions to various industries. Their expertise and dedication to excellence have made them a trusted name in the field, both in China and abroad.Furthermore, the manufacturer's commitment to quality extends beyond product development. They provide comprehensive customer support, ensuring their clients receive adequate training and assistance in utilizing their products effectively. With an extensive network of service centers and a team of experienced technicians, the company prioritizes customer satisfaction and aims to build long-lasting relationships with their clients.The China Sugar Syrup Pump and Sugar Syrup Transfer Pump are a testament to the unwavering spirit of innovation in the Chinese manufacturing industry. These pumps have revolutionized sugar production, streamlining processes, reducing waste, and improving efficiency. With their precision, reliability, and environmental benefits, they have set a new standard for the sugar industry.As the demand for sugar continues to rise, it is evident that these pumps will play a critical role in meeting the industry's needs. Furthermore, they pave the way for other technological advancements in sugar production, emphasizing China's position as a global leader in innovation. With the support of manufacturers like this, the future of sugar production looks brighter than ever.

High-quality Shale Shaker Screen for Solid Control or Desander Applications

Title: Maximizing Efficiency with FLC 48-30 Shaker Screens: A Comprehensive ReviewIntroduction: In the realm of solid control and desanding equipment, the FLC 48-30 Shaker Screens have revolutionized the industry with their impeccable performance and reliable functionality. Designed to optimize efficiency, these Derrick shaker screens have become synonymous with superior quality and exceptional durability. In this blog post, we will delve deeper into the features and benefits of FLC 48-30 Shaker Screens, shedding light on their immense potential in enhancing solid control processes.Understanding FLC 48-30 Shaker Screens:With the key goal of achieving maximum efficiency during solid control or desanding operations, the FLC 48-30 Shaker Screens have emerged as the ideal choice for professionals across industries. These screens are tailor-made to fit the FLC 48-30 / 2000 PWP Shale Shaker, offering a perfect amalgamation of precision and robustness.Key Features:1. Impressive Filtering Capacity: The FLC 48-30 Shaker Screens boast a high-quality mesh material, ensuring exceptional particle separation and perfect cuttings disposal. This enables operators to achieve finer filtration, leading to improved solids removal and enhanced drilling fluid recovery.2. Enhanced Durability: Built to withstand demanding working conditions, FLC 48-30 Shaker Screens exhibit remarkable longevity. Thanks to their superior construction, these screens can withstand heavy usage and maintain their structural integrity, ensuring prolonged operational efficiency.3. Easy Installation and Maintenance: FLC 48-30 Shaker Screens feature user-friendly designs that simplify installation and maintenance processes. With their seamless installation process, these screens enable smooth integration into existing equipment, saving precious time and resources.4. Compatibility and Versatility: These Derrick shaker screens are highly compatible and can be easily fitted into other shaker brands, allowing operators to optimize their existing shaker systems without significant modifications. This versatility provides cost-effective solutions for upgrading and improving solid control operations.Benefits of FLC 48-30 Shaker Screens:1. Optimal Solids Control: The FLC 48-30 Shaker Screens' efficient particle separation capabilities promote higher solids control efficiency, resulting in improved drilling fluid quality. By ensuring finer filtration, these screens minimize the potential for blockages and equipment downtime.2. Cost-Efficiency: By integrating FLC 48-30 Shaker Screens into the solid control process, operators can achieve significant cost savings. The screens' ability to effectively remove solids from drilling mud leads to reduced waste volume, prolonged equipment lifespan, and diminished environmental impact.3. Enhanced Drilling Fluid Recovery: With their exceptional filtering capabilities, these shaker screens enable improved drilling fluid recovery. The removal of unwanted solids reduces fluid wastage, allowing operators to minimize costs associated with fluid replacement.4. Reduced Equipment Maintenance: FLC 48-30 Shaker Screens' efficient particle separation helps to prevent excessive wear on downstream equipment, such as centrifuges and desanders. This leads to decreased maintenance needs and extends the lifespan of auxiliary systems, resulting in reduced operational downtime.Conclusion:As the solid control and desanding processes continue to play a vital role in various industries, the FLC 48-30 Shaker Screens have emerged as an indispensable tool for optimizing efficiency. Their reliability, durability, and impressive filtering capacity make them the prime choice for enhancing solids control operations. By investing in these Derrick shaker screens, operators can unlock substantial gains in terms of cost-efficiency, improved drilling fluid recovery, and reduced equipment maintenance. Embrace the power of FLC 48-30 Shaker Screens today and take your solid control processes to new heights of excellence.

High-Quality Laboratory Sedimentation Centrifuge for Efficient Sample Separation and Analysis

China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge are cutting-edge equipment designed to separate particles from a liquid suspension based on their size, shape, density, and viscosity. These centrifuges are widely used in various industries, including pharmaceuticals, food and beverage, environmental testing, and research laboratories.The Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge are equipped with advanced features, including high-speed rotational capabilities, multiple programmable settings, and precise control over temperature and time. This allows researchers and scientists to achieve a high level of accuracy and reproducibility in their sedimentation experiments.One of the key features of these centrifuges is their ability to accommodate a wide range of sample volumes and densities, making them versatile tools for a diverse range of applications. Additionally, the centrifuges are designed to be easy to operate and maintain, allowing users to focus on their research and experiments without having to worry about the technical aspects of the equipment.The China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge are manufactured by a leading company in the field of laboratory equipment. With a strong emphasis on research and development, the company has continuously improved and refined its centrifuge technology to meet the evolving needs of the scientific community.The company has a long-standing reputation for producing high-quality and reliable laboratory equipment, and its centrifuges are no exception. Through rigorous quality control and testing processes, the company ensures that its centrifuges meet the highest standards of performance and reliability, providing researchers and scientists with the confidence to carry out their experiments with precision and accuracy.Furthermore, the company is committed to providing exceptional customer support, offering comprehensive training, technical assistance, and maintenance services to ensure that its customers can make the most of their centrifuge investment. This dedication to customer satisfaction has earned the company a loyal customer base and a strong reputation in the industry.The China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge have already garnered attention and acclaim from researchers and scientists around the world for their superior performance and reliability. Many leading research institutions and laboratories have adopted these centrifuges as their preferred choice for sedimentation experiments, further solidifying their reputation as a trusted and valuable tool in the scientific community.As the demand for advanced laboratory equipment continues to grow, the company remains at the forefront of innovation, constantly seeking to enhance the capabilities and performance of its centrifuges. With a strong emphasis on precision, efficiency, and user-friendly design, the company is poised to continue leading the way in the development of cutting-edge laboratory equipment for years to come.In conclusion, the China Laboratory Sedimentation Centrifuge and Lab Sedimentation Centrifuge represent the pinnacle of centrifuge technology, offering researchers and scientists a powerful and reliable tool for their sedimentation experiments. Backed by a reputable and innovative company, these centrifuges are set to make a lasting impact on the scientific community, driving advancements in research and technology for years to come.

Drilling Fluids Technology Training Course | Learn Online or In-Person at International Locations

and Training, Drilling Fluids Technology, Mobility Oil & Gas, online training, international training locations.Drilling Fluids Technology: Learn from the Best with Mobility Oil & GasDrilling fluids technology is a crucial aspect of any well drilling process. Whether it's a land-based or offshore drilling project, the right drilling fluid equipment and expertise are necessary for a successful outcome. This is where Mobility Oil & Gas comes in. The company provides comprehensive drilling fluids technology training courses both online and in-person.Mobility Oil & Gas is a leading provider of drilling fluids technology training courses in a variety of drilling-related areas. The company has several years of experience delivering cutting-edge drilling solutions for clients in the oil and gas industry. They have a team of highly trained professionals dedicated to providing industry-leading training and support to drilling professionals around the world.The drilling fluids technology training courses offered by Mobility Oil & Gas cover a wide range of topics, from basic to advanced. The company's instructors are experienced professionals with years of experience in their respective fields. They provide practical insights into the latest industry trends, equipment, and techniques. The courses are designed to meet the needs of professionals at all levels of expertise, from beginner to advanced.Mobility Oil & Gas provides its drilling fluids technology training courses both online and in-person. The online courses are a convenient option for busy professionals who may not be able to attend in-person training. The company employs cutting-edge technology to deliver its online courses in an interactive and engaging manner. Students can learn at their own pace and from the comfort of their homes or offices.In-person training courses are available at several international locations. Mobility Oil & Gas operates in many countries around the world, providing easy access to their training courses. The company has invested heavily in state-of-the-art training facilities that provide a hands-on approach to learning. Students get the opportunity to work with the latest drilling fluid equipment and techniques, ensuring that they are adequately prepared for real-world scenarios.The drilling fluids technology training courses provided by Mobility Oil & Gas are designed to meet the needs of companies of all sizes. Companies can choose to train their entire staff or select individuals they want to develop. The company provides customized training solutions tailored to the needs of each company. This ensures that companies get the maximum return on their investment in training.The drilling fluids technology training courses provided by Mobility Oil & Gas cover a range of topics, including the basics of drilling fluids, advanced drilling fluid equipment and techniques, and best practices for managing drilling fluids. The courses emphasize safety and environmental responsibility and aim at reducing the risks associated with drilling operations. The courses are designed to meet the needs of a diverse range of stakeholders, including drilling engineers, drilling supervisors, drilling fluids engineers, and other personnel involved in drilling operations.In conclusion, drilling fluids technology training is essential to the success of any drilling project. Mobility Oil & Gas provides industry-leading training courses designed to equip drilling professionals with the latest drilling fluid equipment and techniques. The company's courses are available both online and in-person and cover a range of topics. Companies of all sizes can benefit from Mobility Oil & Gas's customized training solutions, ensuring that their staff is adequately prepared for the challenges of drilling operations.

Enhancing Efficiency: Exploring the Benefits of the Swivel Type Mud Gun for Mud Mixing Operations

Swivel Type Mud Gun Enhances Drilling Efficiency for the Oil and Gas IndustryIn the ever-evolving world of drilling operations, the need for efficient and reliable equipment has never been greater. The oil and gas industry seeks cutting-edge technologies that can streamline their processes while ensuring optimal performance. Introducing the revolutionary Swivel Type Mud Gun, a game-changing solution that is set to transform drilling operations worldwide.The Swivel Type Mud Gun, developed by a renowned global company, has quickly gained recognition for its superior quality and performance. With its advanced design and impressive capabilities, this equipment promises to revolutionize the drilling industry by enhancing efficiency and reducing downtime.One of the standout features of the Swivel Type Mud Gun is its exceptional swiveling capability. Unlike conventional mud guns, this innovative equipment offers 360-degree rotation, allowing for better coverage and distribution of drilling fluids. This feature ensures that fluids are evenly dispersed, resulting in improved mud mixing and better control of the drilling process.The equipment's swivel type functionality also enables operators to reach difficult-to-access areas within the drilling system. Whether it be tight corners or complex piping layouts, the Swivel Type Mud Gun provides unparalleled flexibility, ensuring that no part of the system is left untreated. This eliminates the need for manual intervention or the use of additional equipment, saving valuable time and resources.Furthermore, the Swivel Type Mud Gun boasts exceptional durability and longevity. Constructed from high-quality materials, it is designed to withstand harsh drilling conditions and offer reliable performance, even in the most extreme environments. This ensures minimal maintenance requirements and reduces downtime, thereby optimizing drilling operations and maximizing productivity.To further enhance its efficiency, the Swivel Type Mud Gun offers various nozzle options, allowing operators to tailor the equipment to suit specific drilling requirements. The nozzles can easily be interchanged, enabling seamless adaptation to changing drilling conditions or fluid properties. This flexibility ensures optimum mud cleaning and suspension, promoting efficient drilling and minimizing potential issues associated with solids control.Additionally, this groundbreaking equipment is equipped with state-of-the-art control mechanisms. With a user-friendly interface, operators can easily adjust the mud flow and monitor pressure levels to achieve the desired drilling parameters. The intuitive design reduces the learning curve for operators and enables efficient utilization of the equipment, regardless of their level of expertise.Among the many advantages of the Swivel Type Mud Gun, its compatibility with automation technology stands out. As the drilling industry progresses towards increased automation, this equipment seamlessly integrates with drilling control systems. This facilitates real-time monitoring, data analysis, and remote control capabilities, revolutionizing the way drilling operations are managed and monitored.The Swivel Type Mud Gun's potential impact on the drilling industry has not gone unnoticed. Industry experts have hailed this equipment as a significant advancement, with its ability to optimize drilling operations, improve efficiency, and reduce costs. Its unique features, combined with the company's unwavering commitment to quality and innovation, position it as a market leader in drilling equipment.With the Swivel Type Mud Gun, the oil and gas industry can expect enhanced drilling efficiency, reduced downtime, and improved overall performance. As this equipment continues to gain traction and recognition globally, it is set to reshape the drilling landscape, setting a new standard for excellence in the industry.

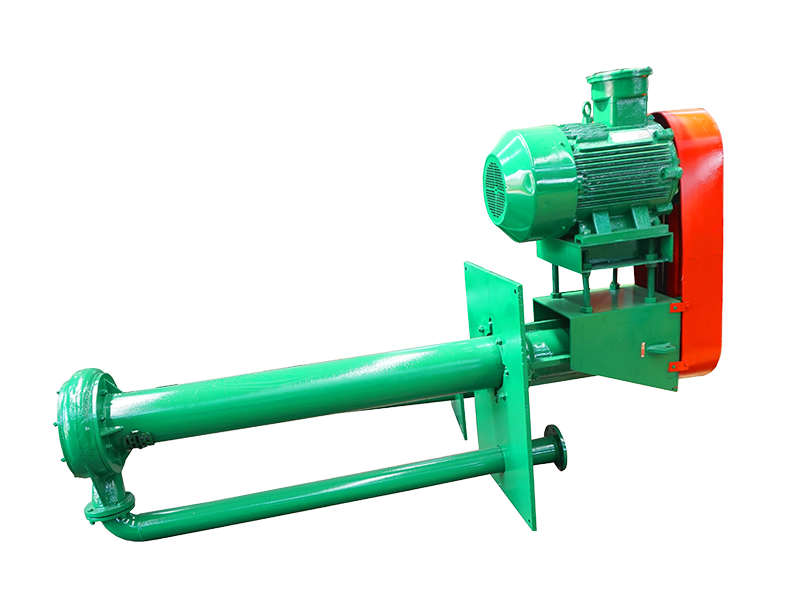

Powerful Fluid Agitator for Efficient Mixing and Blending

The fluid industry is constantly evolving, with new technologies and innovations emerging to meet the demand for more efficient and effective solutions. One company at the forefront of this industry is {Company Name}, a leading provider of fluid agitators and mixing equipment.With a strong focus on research and development, {Company Name} has developed a range of innovative fluid agitators that are designed to meet the diverse needs of the industry. These products are engineered to provide reliable and efficient mixing solutions for a wide range of applications, from simple blending to complex chemical reactions.One of the company's flagship products is the {Fluid Agitator}, a state-of-the-art mixing system that is designed to deliver powerful and consistent agitation. Equipped with advanced technology and precision engineering, the {Fluid Agitator} is capable of handling a wide range of viscosities and densities, making it suitable for a diverse range of fluid mixing applications.The {Fluid Agitator} is equipped with a high-torque motor and a durable, corrosion-resistant impeller, ensuring reliable performance and long-term durability. It also features a user-friendly control system that allows operators to easily adjust the speed and intensity of the agitation, ensuring precise control over the mixing process.In addition to its advanced technology and high-performance capabilities, the {Fluid Agitator} is also designed with safety and environmental sustainability in mind. It incorporates advanced safety features to protect operators and the surrounding environment, and is engineered to minimize energy consumption and reduce the environmental impact of fluid mixing processes.{Company Name} takes great pride in its commitment to quality and customer satisfaction. The company's team of skilled engineers and technicians work closely with customers to understand their specific requirements and provide customized solutions to meet their unique needs. From initial design and engineering to installation and ongoing support, {Company Name} is dedicated to delivering exceptional products and services to its customers.In addition to its innovative products, {Company Name} also offers a range of value-added services to support its customers. This includes comprehensive technical support, maintenance and repair services, and training programs to ensure that operators are able to maximize the performance and lifespan of their fluid agitators.The company's commitment to excellence has earned it a strong reputation within the industry, with a growing portfolio of satisfied customers across a diverse range of sectors, including chemical processing, food and beverage production, pharmaceuticals, and many more.Looking to the future, {Company Name} is committed to ongoing innovation and development, continuously pushing the boundaries of fluid mixing technology to deliver even more advanced and efficient solutions to the industry. With a focus on quality, performance, and sustainability, {Company Name} is well-positioned to continue leading the way in the fluid agitator market.In conclusion, {Company Name} is a leading provider of innovative fluid agitators and mixing equipment, with a strong commitment to quality, performance, and customer satisfaction. With a focus on advanced technology, reliability, and sustainability, {Company Name} is well-equipped to meet the evolving needs of the fluid industry and deliver exceptional solutions to its customers.

Ultimate Guide to Decanter Centrifuge Diagrams

Decanter Centrifuge Diagram and its Application in Various IndustriesA decanter centrifuge is a versatile piece of equipment that is used in a wide range of industries for liquid-solid separation. The diagram of a decanter centrifuge shows the various components and their functions in the separation process. With its efficient and effective design, decanter centrifuges have become essential in industries such as wastewater treatment, oil and gas, food and beverage, pharmaceuticals, and many more.A typical decanter centrifuge consists of a rotating bowl, screw conveyor, and drive system. The bowl rotates at high speeds, creating centrifugal force that causes the solids to settle at the bowl wall while the liquid phases out through the conveyor. The diagram illustrates how the conveyor then moves the separated solids to one end of the centrifuge while the liquid is discharged from the other end.One of the leading manufacturers of decanter centrifuges has been {Company Name}. With years of experience and expertise in the industry, they have been providing high-quality and reliable decanter centrifuges for various applications. Their decanter centrifuge diagram showcases the innovative design and technology that sets their products apart from the competition.The diagram also illustrates the versatility of decanter centrifuges in various industries. In wastewater treatment, decanter centrifuges are crucial for separating sludge from water, allowing for the efficient and cost-effective treatment of wastewater. In the oil and gas industry, decanter centrifuges are used for the separation of oil, water, and solids in drilling muds and produced water. The diagram also demonstrates how decanter centrifuges are utilized in the food and beverage industry for the clarification of liquids and separation of solids from slurries.Moreover, in the pharmaceutical industry, decanter centrifuges play a vital role in the separation and purification of active ingredients, as well as the recovery of solvents and the processing of biological products. The diagram further highlights the use of decanter centrifuges in the mining and mineral processing industry for dewatering and tailings management, as well as in the chemical industry for the separation of liquid-liquid and liquid-solid mixtures.As a leading manufacturer in the industry, {Company Name} has continuously strived to innovate and improve their decanter centrifuges to meet the evolving needs of various industries. Their dedication to research and development is evident in the design and features outlined in the decanter centrifuge diagram. With a focus on efficiency, reliability, and ease of maintenance, their decanter centrifuges have become the preferred choice for many companies around the world.In addition to providing high-quality equipment, {Company Name} also offers comprehensive support and services to ensure the smooth operation of their decanter centrifuges. Their team of experts is available to provide technical assistance, maintenance, and training to their customers, ensuring the optimal performance of their decanter centrifuges.In conclusion, the decanter centrifuge diagram provides a comprehensive overview of the technology and applications of this essential piece of equipment. With {Company Name} at the forefront of innovation, the diagram showcases the advanced features and capabilities of their decanter centrifuges. As industries continue to evolve, the versatility and efficiency of decanter centrifuges will remain crucial in a wide range of applications, making them indispensable for various separation processes.