Metal Scale Briquetter and Metal Swarf Briquetter in China: What You Need to Know

By:Admin

The Metal Scale Briquetter and Metal Swarf Briquetter are designed to efficiently compress and compact metal scraps, such as steel, aluminum, and copper, into dense and manageable briquettes. This process not only reduces the volume of metal waste but also facilitates its storage, transportation, and recycling. With an increasing focus on sustainable and eco-friendly practices, these briquetters offer a cost-effective and environmentally responsible solution for industries dealing with metal waste.

The Metal Scale Briquetter is specifically engineered to handle large and bulky metal scraps, such as metal scales and residues generated during manufacturing processes. By transforming these unwieldy materials into compact briquettes, companies can streamline their waste management operations and optimize their recycling efforts. This not only contributes to a cleaner and greener environment but also enhances the overall efficiency and productivity of metal processing facilities.

On the other hand, the Metal Swarf Briquetter is designed to tackle smaller metal chips, shavings, and swarf that are produced during machining, cutting, and shaping operations. These fine metal particles can be challenging to handle and store due to their loose and scattered nature. However, the Metal Swarf Briquetter can effectively compress this metal waste into dense briquettes, making it easier to store, transport, and recycle. This process minimizes the risk of metal spillage and contamination, creating a safer and more organized work environment.

Both the Metal Scale Briquetter and Metal Swarf Briquetter incorporate advanced technology and automation, allowing for seamless integration into existing production lines and waste management systems. Equipped with user-friendly controls and monitoring features, these machines offer operators a convenient and efficient means of managing metal waste. Additionally, they are designed for durability and reliability, ensuring long-term performance and low maintenance requirements.

The use of Metal Scale Briquetter and Metal Swarf Briquetter not only benefits individual companies but also contributes to larger environmental and sustainability goals. By compacting metal waste into briquettes, these machines reduce the demand for raw materials, lower energy consumption, and minimize the carbon footprint associated with metal production and processing. This aligns with the global push towards circular economy principles, where resources are conserved, reused, and recycled in a closed-loop system.

Furthermore, the Metal Scale Briquetter and Metal Swarf Briquetter support the transition towards a circular economy by promoting the responsible management of metal waste. As industries strive to minimize their impact on the environment and comply with regulatory standards, these machines offer a practical and proactive solution for handling metal scraps. By investing in technology that prioritizes sustainability and efficiency, companies can position themselves as leaders in their respective sectors and contribute to a more sustainable future.

In conclusion, the introduction of the Metal Scale Briquetter and Metal Swarf Briquetter represents a significant advancement in metal recycling and waste management. With their ability to compress and compact metal scraps into dense briquettes, these machines offer a practical and sustainable solution for handling metal waste. Backed by a reputable and innovative technology company, these briquetters are poised to make a positive impact on the environment and the industry as a whole. As industries continue to prioritize environmental responsibility and resource efficiency, the Metal Scale Briquetter and Metal Swarf Briquetter emerge as essential tools for sustainable metal processing and recycling.

Company News & Blog

Durable Urethane Panel for Various Applications - Ultimate Guide

Leading Urethane Panel Manufacturer Introduces TH48-30X.85MT Urethane PanelThe renowned urethane panel manufacturer, known for its commitment to quality and innovation, has introduced their latest product - the TH48-30X.85MT Urethane Panel. This new addition to their extensive range of urethane panels is set to revolutionize the industry with its advanced features and unparalleled performance.The TH48-30X.85MT Urethane Panel is designed to meet the diverse needs of various industries, including mining, construction, and agriculture. The company has leveraged its expertise and state-of-the-art manufacturing facilities to create a product that offers exceptional durability, wear resistance, and impact strength. This makes it an ideal solution for applications that require reliable and long-lasting performance, even in the most demanding environments.One of the key highlights of the TH48-30X.85MT Urethane Panel is its unique formulation, which incorporates high-quality materials to deliver exceptional performance. The company's team of experts has meticulously developed the urethane panel to ensure that it meets the highest industry standards and exceeds customer expectations. Additionally, the panel is engineered to provide superior flexibility and resilience, enabling it to withstand heavy loads and abrasive materials without compromising its integrity.The TH48-30X.85MT Urethane Panel also boasts a specially designed surface that minimizes material buildup and reduces maintenance requirements. This feature is particularly beneficial for industries such as mining and quarrying, where material buildup can hamper equipment performance and lead to costly downtime. By incorporating this innovative design, the company has demonstrated its commitment to providing practical solutions that address the real-world challenges faced by its customers.Moreover, the company's commitment to sustainability is reflected in the TH48-30X.85MT Urethane Panel, which is manufactured using environmentally friendly processes and materials. This aligns with the company's vision of promoting sustainable practices while delivering high-performance products to its customers. By choosing the TH48-30X.85MT Urethane Panel, customers can contribute to their environmental efforts without compromising on quality or performance.In addition to its impressive technical specifications, the TH48-30X.85MT Urethane Panel is backed by the company's renowned customer support and technical assistance. The company's team of experts is dedicated to helping customers choose the right products for their specific applications and providing ongoing support to ensure optimal performance and longevity. This comprehensive approach sets the company apart in the industry and reinforces its position as a trusted partner for businesses around the world.As the company expands its product portfolio with the introduction of the TH48-30X.85MT Urethane Panel, customers can look forward to a wider range of options that cater to their evolving needs. The company's relentless pursuit of innovation and improvement is driven by its dedication to delivering value to its customers and setting new benchmarks in the industry. With their extensive experience and commitment to excellence, customers can trust that the company will continue to lead the way in urethane panel solutions.In conclusion, the introduction of the TH48-30X.85MT Urethane Panel marks a significant milestone for the leading urethane panel manufacturer. With its advanced features, exceptional performance, and commitment to sustainability, the TH48-30X.85MT Urethane Panel is set to redefine industry standards and exceed customer expectations. As the company continues to innovate and expand its product offerings, customers can rely on its expertise and support to drive their success.

High Quality PWP Shaker Screens for FLC 2000 Model Available

FLC 2000 PWP Shaker Screens Revolutionize the Oil and Gas Drilling IndustryThe oil and gas drilling industry is continuously evolving, and with advancements in technology, companies are constantly searching for ways to improve efficiency and productivity. One of the key components of any drilling operation is the shaker screen, which is essential for separating solids from drilling fluid. With the introduction of the FLC 2000 PWP Shaker Screens, the drilling industry has been revolutionized, offering enhanced performance and reliability for drilling operations worldwide.The FLC 2000 PWP Shaker Screens, produced by a leading manufacturer in the industry, have set a new standard for shaker screen technology. These screens are specifically designed to provide superior performance in a wide range of drilling applications, including oil and gas exploration, geothermal drilling, and more. With a focus on durability, efficiency, and reliability, these screens are engineered to withstand the demanding conditions of drilling operations, delivering exceptional results time and time again.One of the key features of the FLC 2000 PWP Shaker Screens is their advanced design, which allows for maximum fluid handling capacity while effectively removing solid particles from the drilling fluid. This results in improved drilling efficiency, reduced downtime, and lower overall operating costs. Additionally, these screens are built to withstand the harsh conditions of drilling operations, ensuring long-lasting performance and reliability in the field.In addition to their superior performance, the FLC 2000 PWP Shaker Screens are also designed with ease of use in mind. With quick and simple installation, these screens can be easily integrated into existing shaker systems, providing immediate improvements in performance and efficiency. This user-friendly design has been well-received by drilling operators, who have praised the FLC 2000 PWP Shaker Screens for their ease of use and reliability in the field.Furthermore, the manufacturer of the FLC 2000 PWP Shaker Screens has a long-standing reputation for producing high-quality products that meet the needs of the oil and gas industry. With a commitment to innovation and excellence, this company has become a trusted partner for drilling operations around the world, providing solutions that improve efficiency, productivity, and safety.The introduction of the FLC 2000 PWP Shaker Screens has generated significant interest and excitement within the oil and gas drilling industry. Drilling operators are eager to take advantage of the enhanced performance and reliability offered by these innovative screens, which have the potential to revolutionize the way drilling operations are conducted. With their advanced design, durability, and ease of use, the FLC 2000 PWP Shaker Screens are poised to make a significant impact on the industry, setting a new standard for shaker screen technology.Overall, the FLC 2000 PWP Shaker Screens represent a significant advancement in shaker screen technology, offering enhanced performance and reliability for drilling operations worldwide. With their advanced design, durability, and ease of use, these screens have the potential to revolutionize the oil and gas drilling industry, providing operators with the tools they need to improve efficiency, productivity, and safety. As the industry continues to evolve, the FLC 2000 PWP Shaker Screens are sure to play a key role in driving future advancements and innovations in drilling technology.

China Separation Industries Discover the Excellence of Hydrocarbon Recovery Equipment in Solids Control Industries

As industries continue to grow in China, the need for efficient and effective separation equipment has become increasingly important. GN Solids Control, a leading manufacturer of drilling fluids recycling equipment, has expanded their offerings to include hydrocarbon recovery equipment, making them a standout in the separation industry.One of the key areas of focus for GN Solids Control is their solid liquid separator, which effectively removes solids from drilling fluids. This is crucial in the drilling process, as the removal of solids ensures that the drilling fluids can be reused and recycled, reducing waste and cutting down on costs.But GN Solids Control's product offerings go beyond just drilling fluids recycling equipment. Their 3-phase separation filter is another standout product that has garnered attention in the separation industry in China. This filter is designed to separate liquids and solids of different densities, as well as oil and water, making it ideal for use in a variety of industries.One of the biggest advantages of GN Solids Control's products is their efficiency. The solid liquid separator and 3-phase separation filter are designed to operate at a high processing rate, enabling customers to achieve greater productivity and throughput.But efficiency is only part of the equation. GN Solids Control's products are also designed with durability and reliability in mind. They are built to last, even in the harshest of operating conditions. This makes them an excellent investment for any business looking to streamline their operations and improve their bottom line.In addition to their high-quality products, GN Solids Control is known for their exceptional customer service and technical support. They have a team of experienced professionals who are dedicated to helping customers get the most out of their equipment. Whether they need assistance with installation, training, or ongoing maintenance, GN Solids Control is there to help every step of the way.Overall, GN Solids Control's hydrocarbon recovery equipment has made them a standout in the separation industry in China. Their solid liquid separator and 3-phase separation filter are both efficient and reliable, making them an excellent investment for any business in need of separation equipment. And with their exceptional customer service and technical support, customers can rest assured that they are in good hands with GN Solids Control.

Advanced Circulating System for Efficient Drilling Operations

Circulating System In Drilling Enhances Efficiency and SafetyThe drilling industry plays a crucial role in extracting natural resources from deep beneath the earth's surface. To maximize efficiency and ensure safety during drilling operations, the implementation of advanced technology and equipment is essential. One such innovation that has significantly contributed to these goals is the Circulating System in drilling.A circulating system is a critical component of the drilling process, providing a means to circulate drilling fluid or mud, which helps to remove cuttings from the wellbore, control pressure, and aid in the overall stability of the well. This technology has become increasingly paramount in achieving optimal drilling performance, and the application of this system has been proven to enhance efficiency and safety.With the increasing demand for drilling operations on land and offshore, companies like {} have recognized the importance of investing in advanced circulating systems to meet the industry's evolving needs. As a leading provider of drilling equipment and services, {} has made significant strides in developing and implementing cutting-edge technologies to support the efficient and safe extraction of natural resources.The company's circulating system features state-of-the-art pumps, valves, and control systems that are designed to optimize the circulation of drilling mud, providing a consistent flow and pressure throughout the wellbore. This not only allows for the efficient removal of cuttings but also helps to maintain well control and prevent potential hazards associated with pressure imbalances during drilling operations.In addition to enhancing efficiency, the circulating system also contributes to the safety of drilling operations. By maintaining the stability and integrity of the wellbore, the risk of wellbore collapse or blowouts is significantly reduced. Furthermore, the system's advanced control features enable real-time monitoring and adjustments, ensuring that drilling operations are conducted with the highest level of safety standards.The benefits of implementing an advanced circulating system are evident in the improved performance and outcomes of drilling operations. By optimizing the circulation of drilling mud, operators can achieve faster and more cost-effective drilling processes, resulting in increased productivity and profitability. Furthermore, the enhanced safety features of the system provide peace of mind for all stakeholders involved in drilling projects.As the demand for natural resources continues to grow, the importance of efficient and safe drilling practices becomes increasingly critical. Companies like {} are at the forefront of developing and implementing innovative technologies to meet these demands. With a commitment to excellence and a focus on continuous improvement, the company is dedicated to providing the industry with reliable and advanced drilling solutions.In conclusion, the incorporation of a Circulating System in drilling has proven to be instrumental in enhancing efficiency and safety in drilling operations. Companies like {} have recognized the importance of this technology and have made significant investments to develop and implement advanced circulating systems that meet the evolving needs of the industry. With a focus on innovation and excellence, these advancements are pivotal in ensuring the sustainable and responsible extraction of natural resources for the benefit of future generations.

Efficient and Reliable Drilling Machines: Unveiling the Power of Drilling

[Company Name] Introduces Advanced Drilling Machine for Enhanced Drilling Operations[date][city, state] - In a bid to revolutionize drilling operations globally, [Company Name], a leader in the manufacturing of cutting-edge industrial machinery, announced the release of their latest drilling machine. The new technology promises to revolutionize the drilling industry by providing enhanced efficiency, versatility, and precision.Designed for both industrial and residential applications, the new drilling machine boasts state-of-the-art features that push the boundaries of current drilling capabilities. With its advanced technology and innovative design, [Company Name] aims to meet the growing demand for more efficient and productive drilling operations worldwide.The key feature of the new drilling machine is its advanced drilling technology, which allows for deeper and more precise drilling. Equipped with a powerful motor and specialized drill bits, this machine can effortlessly penetrate various materials, including concrete, metal, and wood. Its high torque capabilities ensure smooth operation even in the toughest drilling conditions.Additionally, the drilling machine incorporates intelligent automation features that increase operator safety and streamline operations. The inclusion of an automatic feed system ensures consistent drilling depth, negating the need for manual adjustments. This feature not only reduces operator workload but also minimizes drilling errors, resulting in better quality and reliable drilling outputs.Furthermore, the drilling machine offers exceptional versatility with its adjustable speed settings. Whether drilling delicate materials that require slow drilling or tackling heavy-duty tasks that demand high-speed drilling, this machine can cater to different drilling needs. This adaptability ensures that operators can achieve optimal results regardless of the drilling requirements, making it an ideal choice for various industries.In line with [Company Name]'s commitment to sustainability, the drilling machine incorporates eco-friendly features. With energy-efficient motors, reduced noise emissions, and ergonomic design, the machine helps minimize environmental impact while providing a comfortable working environment for operators. By prioritizing sustainability, [Company Name] aims to contribute to a greener future for the drilling industry.To ensure the seamless integration of the drilling machine into various drilling processes, [Company Name] provides comprehensive technical support and maintenance services. Their team of experienced engineers and technicians is readily available to assist clients with installation, training, and troubleshooting. This dedication to excellent customer service reinforces [Company Name]'s commitment to delivering not just top-notch products but also complete customer satisfaction."We are thrilled to introduce our latest drilling machine to the market," said [Spokesperson Name], a representative from [Company Name]. "We believe that this technology will revolutionize the way drilling operations are conducted, offering unparalleled efficiency and precision. We are confident that our clients will greatly benefit from this breakthrough in drilling technology."With its cutting-edge features, versatility, and dedication to sustainability, [Company Name]'s new drilling machine is set to make waves in the drilling industry. As the demand for more efficient drilling practices grows, this technology could pave the way for enhanced productivity and cost savings while reducing environmental impact. [Company Name] continues to drive innovation, setting its sights on transforming the drilling landscape on a global scale.Contact:[Company Name][Contact Person][Phone number][Email address][Website URL]

Balancing Budget and Quality for Maximum Effectiveness in Horizontal Directional Drilling Projects

China Drilling Desilter and Drilling Machine: Leaders in the Horizontal Directional Drilling IndustryFounded in China, China Drilling Desilter and Drilling Machine are leaders in the horizontal directional drilling industry, manufacturing and selling some of the best HDD (Horizontal Directional Drilling) machines and drilling mud solids control systems on the market. Their reputation for quality and innovation in the industry is second to none, leading to the company becoming one of the fastest-growing enterprises in the field of no-dig technology.The company has state-of-the-art manufacturing facilities with cutting-edge technology such as EDM (Electrical Discharge Machining) and CNC Lathe, enabling them to produce quality HDD machines that meet the needs of their clients. Their workforce consists of well-trained experts in no-dig technology, with years of experience in the industry, ensuring that the end products they produce perfectly meet their customers' needs.One of the prominent HDD machines they manufacture is the Vermeer NAVIGATOR line. The Vermeer NAVIGATOR line of HDD machines is ideal for installing gas, electric, water, telecommunication, or soil remediation lines without excavation or trenching. It is a reliable and robust HDD machine that can undertake demanding projects, such as large-scale infrastructure projects, including laying utility pipes or performing soil remediation.Another HDD machine manufactured by China Drilling Desilter and Drilling Machine is the Drillto HDD machine. The company's multi-faceted manufacturing facility can produce this machine, allowing them to address the needs of their diverse range of customers. These two HDD machines have an excellent reputation in the industry, delivering high-quality work output and lasting performance.The company also produces drilling mud solids control systems that enable their clients to efficiently handle and filter drilling mud. These mud systems work by removing solids from the drilling mud while returning clean fluid back to the drilling process. GN solids control is an example of a drilling mud processing supplier that China Drilling Desilter and Drilling Machine has partnered with, providing their clients with efficient and reliable mud processing systems.When it comes to an HDD project, ensuring that you have a balance between budget and quality is an essential consideration. Therefore, it is crucial to use world-renowned drilling machines such as those produced by China Drilling Desilter and Drilling Machine. When combined with efficient mud processing systems from reputed companies like GN solids control, you can achieve maximum project effectiveness.The reputation China Drilling Desilter and Drilling Machine have built over the years is a testament to the quality and reliability of their products. The company operates with purpose, committed to ensuring their customers' needs are met by delivering high-quality products that meet industry standards.In conclusion, China Drilling Desilter and Drilling Machine stand out among the industry's brightest stars, providing high-quality HDD machines and drilling mud solids control systems. Considering their reputation for delivering quality products, their commitment to improving their products as per industry standards, there's no doubt that they are one of the most reputable companies in the industry.

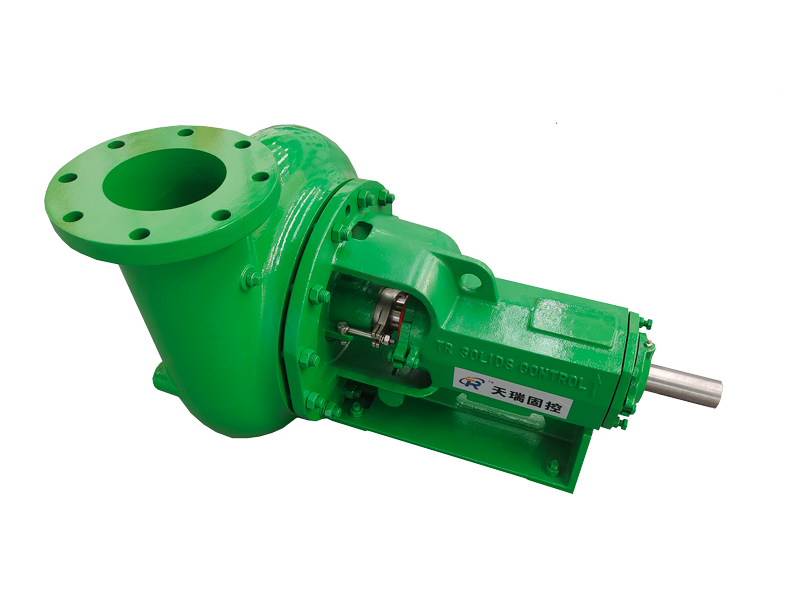

High-quality ANSI Pump Parts and Process Pump Parts Made in China

China ANSI Pump Parts and Process Pump PartsChina has long been known for its strong manufacturing and industrial capabilities. One key area where China has excelled is in the production of pump parts for a wide range of applications. One such area of expertise is in the production of ANSI pump parts and process pump parts.An ANSI pump is a type of centrifugal pump that meets the standards set by the American National Standards Institute (ANSI). These pumps are commonly used in a variety of industries, including the chemical, petrochemical, and water treatment industries. Process pump parts, on the other hand, are components that are used in various types of industrial pumps to ensure their smooth and efficient operation.China has become a major player in the global market for ANSI pump parts and process pump parts. The country's manufacturing facilities are capable of producing high-quality parts that meet the stringent requirements of industries around the world. In fact, many companies in the United States and Europe rely on Chinese manufacturers to supply them with these critical components.One company that has established itself as a leader in the production of ANSI pump parts and process pump parts is {}. The company has been in the business for over 20 years and has developed a strong reputation for delivering top-quality products to its customers. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, {} has the capabilities to meet the needs of even the most demanding customers.{} offers a wide range of ANSI pump parts and process pump parts, including impellers, casings, shafts, and seals. These components are designed and manufactured to meet the highest standards of quality and reliability, ensuring that they can withstand the rigors of the most demanding industrial applications. The company also provides custom machining services, allowing it to produce parts that are tailored to the specific requirements of its customers.In addition to its manufacturing capabilities, {} is also committed to providing exceptional customer service. The company works closely with its customers to understand their needs and ensure that they receive the right parts for their applications. Whether a customer requires a standard component or a custom-made part, {} is dedicated to delivering the highest level of support and satisfaction.With its strong manufacturing capabilities and commitment to customer service, {} has positioned itself as a leading supplier of ANSI pump parts and process pump parts in the global market. The company's parts are used in a wide range of applications, including chemical processing, oil and gas production, and water treatment. As industries around the world continue to rely on these critical components, {} is poised to play a key role in meeting their needs.As the demand for ANSI pump parts and process pump parts continues to grow, China's manufacturing industry is likely to play an increasingly important role in meeting this demand. With companies like {} leading the way, China is well-positioned to continue supplying the world with the high-quality components it needs to keep industrial processes running smoothly and efficiently.

Innovative Centrifuge Drilling Technology for Efficient and Effective Drilling Operations

Centrifuge Drilling is revolutionizing the oil and gas industry with its cutting-edge technology that allows for more efficient and cost-effective drilling. This innovative company has quickly become a leader in the field, providing solutions that are changing the way companies approach drilling operations.Founded in 2010, Centrifuge Drilling has a mission to improve the efficiency and effectiveness of drilling for oil and gas reserves. The company specializes in the development and manufacturing of advanced drilling equipment, including centrifuges, that are designed to enhance performance and reduce costs for its customers.Centrifuge Drilling's technology is based on the principle of using centrifugal force to separate different components of drilling mud, allowing for better control and management of the drilling process. This results in improved drilling performance, reduced downtime, and ultimately, significant cost savings for operators.One of the key advantages of Centrifuge Drilling's technology is its ability to handle a wide range of drilling conditions, making it suitable for both onshore and offshore operations. Additionally, the company's equipment is designed to be highly adaptable, allowing for easy integration into existing drilling rigs.The company has quickly gained recognition for its innovative approach to drilling, and it has already established a strong track record of success with numerous projects around the world. Centrifuge Drilling's technology has been proven to significantly improve drilling efficiency and reduce operational costs, making it an attractive solution for operators looking to maximize their resources.One of the company's flagship products is its centrifuge system, which has been specifically designed to address the challenges of drilling in complex geological formations. This system can effectively separate solids from drilling mud, allowing for better control of viscosity and density, which in turn leads to improved drilling performance and reduced wear and tear on equipment.In addition to its cutting-edge technology, Centrifuge Drilling also offers comprehensive support services to its customers. The company's team of experts is available to provide technical assistance, training, and maintenance services to ensure the continued success of its technology in the field.Centrifuge Drilling's commitment to innovation and excellence has earned it a reputation as a trusted partner for operators in the oil and gas industry. The company's dedication to providing reliable, cost-effective solutions has helped it build strong relationships with a wide range of clients, from small independent operators to major international companies.Looking ahead, Centrifuge Drilling is focused on continued research and development to further enhance its technology and maintain its position as a leader in the field. The company is also exploring new opportunities to expand its presence in key markets and build on its success in providing innovative solutions for the oil and gas industry.As the demand for efficient and sustainable drilling continues to grow, Centrifuge Drilling is well-positioned to play a key role in shaping the future of the industry. With its proven technology and commitment to excellence, the company is poised to make a lasting impact on the way drilling operations are conducted around the world.

Highly Efficient Screw Pump: A Breakthrough in Pump Technology

Screw Pump Technology Revolutionizes Industrial Fluid HandlingIndustrial fluid handling has always been a critical aspect of various manufacturing processes. Whether it’s transferring chemicals, oil, or wastewater, the efficiency and reliability of the pumping system play a crucial role in maintaining the overall productivity of the operation. In this context, the introduction of the innovative Screw Pump technology by [Company] has revolutionized the way industrial fluids are handled and transferred.[Company] is a leading provider of innovative pumping solutions for a wide range of industrial applications. With a focus on delivering high-performance and reliable products, the company has built a reputation for excellence and innovation in the fluid handling industry. The latest addition to their product line, the Screw Pump, is not only a testament to their commitment to innovation but also a game-changer in the industry.The Screw Pump technology is based on the principle of positive displacement, where the fluid is moved through the pump in a smooth and consistent manner, resulting in stable flow rates and minimal pulsation. This makes it an ideal choice for applications where precision and accuracy are crucial, such as in chemical processing and oil refineries. Furthermore, the design of the Screw Pump allows for handling a wide range of viscosities, from low to high, without sacrificing performance, making it a versatile solution for various industrial fluid handling needs.One of the key features of the Screw Pump is its ability to handle abrasive and shear-sensitive fluids with ease. This is achieved through the use of robust materials and an advanced design that minimizes wear and tear, thus extending the lifespan of the pump and reducing maintenance costs. In addition, the Screw Pump is equipped with a sealing system that effectively prevents leakage, ensuring the safety and reliability of the pumping operation.The efficiency of the Screw Pump is also worth noting, as it can deliver high flow rates with minimal energy consumption. This not only reduces operational costs but also contributes to environmental sustainability by minimizing energy usage and reducing carbon emissions. The compact design of the Screw Pump further adds to its appeal, as it can be easily integrated into existing systems or installed in limited spaces, saving valuable floor space in industrial facilities.With its advanced technology and robust construction, the Screw Pump has quickly gained recognition in the industrial fluid handling market. [Company] has received positive feedback from customers who have implemented the Screw Pump in their operations, citing its reliability, efficiency, and low maintenance requirements as key factors in their satisfaction. The company’s commitment to providing exceptional customer support further enhances the overall experience of integrating the Screw Pump into industrial processes.Looking ahead, [Company] is dedicated to further enhancing the Screw Pump technology, with ongoing research and development efforts aimed at introducing new features and improvements to meet the evolving needs of the industry. As a forward-thinking and customer-focused company, [Company] is dedicated to continuous innovation and excellence in providing pumping solutions that drive the success of industrial operations around the world.In conclusion, the introduction of the Screw Pump by [Company] signifies a new era in industrial fluid handling, offering a combination of efficiency, reliability, and versatility that sets a new standard for pumping technology. With its advanced design and proven performance, the Screw Pump has quickly established itself as a preferred choice for a wide range of industrial applications, reaffirming [Company]’s position as a leader in the fluid handling industry.

High-Quality Hydraulic Mud Agitator for Solid Control and Oil Drilling in China

, Hydraulic Mud Agitator, Oil Drilling, Solid Control, and China.Solid Control Liquid Mixer Agitator / Hydraulic Mud Agitator For Oil Drilling: The Ultimate Solution for your Drilling NeedsOil drilling is one of the most complex and demanding industries in the world. It requires top-notch equipment and tools to extract valuable resources from the earth's core efficiently. One of the critical components in achieving this is the solid control liquid mixer agitator/hydraulic mud agitator.A solid control liquid mixer agitator/hydraulic mud agitator is a device that ensures the proper mixing of drilling fluids in a mud tank. The mud tank is an integral part of the drilling process as it acts as a reservoir for the drilling mud, which is responsible for cooling and lubricating drill bits, controlling wellbore pressure, and carrying out cuttings from the drill bit to the surface.China has been at the forefront of producing high-quality solid control liquid mixer agitators/hydraulic mud agitators for the oil drilling industry. China's relentless pursuit of quality has made it a leader in the manufacture of fluid mixing equipment, making it a trusted partner to global oil drilling companies.In this blog, we will examine the importance of solid control liquid mixer agitators/hydraulic mud agitators in oil drilling, their features, and why choosing China-made products is a wise decision.Importance of Solid Control Liquid Mixer Agitators/Hydraulic Mud Agitators in Oil DrillingAs earlier mentioned, a mud tank is integral to the oil drilling process. It is responsible for storing drilling mud, which plays a critical role in ensuring a successful drilling process. Drilling mud is a mixture of water, clay, and other chemicals that cool and lubricate drilling bits, control wellbore pressure, carry cuttings from the drill bit to the surface, and prevent the formation of fractures.Maintaining the right consistency and homogeneity of the drilling mud is crucial to the efficiency of the drilling process. This is where the solid control liquid mixer agitator/hydraulic mud agitator comes in. It ensures even distribution of drilling mud, eliminates dead areas, and prevents the formation of lumps and sediments that can clog the drill bit.Features of Solid Control Liquid Mixer Agitators/Hydraulic Mud AgitatorsSolid control liquid mixer agitators/hydraulic mud agitators are built to withstand the harsh conditions of the oil drilling industry. Some of the features that make them suitable for this industry include:1. High-quality materials - Solid control liquid mixer agitators/hydraulic mud agitators are made of top-quality materials such as high-strength steel and abrasion-resistant polyurethane. This makes them durable and robust, capable of withstanding harsh operating conditions.2. Low maintenance - Solid control liquid mixer agitators/hydraulic mud agitators require minimal maintenance, making them cost-effective. This is due to their simple design, which makes it easy to access and replace components.3. High efficiency - Solid control liquid mixer agitators/hydraulic mud agitators are designed for high-efficiency mixing of drilling mud. The agitators are powerful and have a high torque, which ensures even mixing of the drilling mud, preventing the formation of lumps and sediments.Why Choose China-made Solid Control Liquid Mixer Agitators/Hydraulic Mud Agitators?China is a global leader in the manufacture of fluid mixing equipment, including solid control liquid mixer agitators/hydraulic mud agitators. The country has invested heavily in research and development, which has resulted in the production of high-quality products that meet global standards.China-made solid control liquid mixer agitators/hydraulic mud agitators are affordable without compromising on quality. They are also readily available in the market, making them a top choice for oil drilling companies looking for reliable equipment at a reasonable price.ConclusionSolid control liquid mixer agitators/hydraulic mud agitators are indispensable components in the oil drilling industry. Choosing high-quality products such as those from China ensures efficient, safe, and cost-effective drilling operations. With China's commitment to producing top-quality fluid mixing equipment, oil drilling companies can rely on their products to meet their drilling requirements.