Highly Efficient Glass Washing and Drying Machines from China for All Your Needs

By:Admin

China Glass Washing Machine is a leading manufacturer of glass processing equipment, specializing in the production of glass washing machines. These machines are designed to effectively clean glass surfaces, removing dirt, dust, and other impurities to ensure a spotless finish. With their advanced technology and precise control systems, China Glass Washing Machine has set a new standard for glass washing equipment.

Similarly, Glass Washing and Drying Machine has made a name for itself as a top-tier supplier of glass processing machinery. The company's glass washing and drying machines are known for their exceptional performance and reliability. With a focus on quality and efficiency, Glass Washing and Drying Machine has become a trusted partner for businesses looking to enhance their glass processing capabilities.

One of the key factors contributing to the success of these machines is the use of advanced technology. China Glass Washing Machine and Glass Washing and Drying Machine have both incorporated cutting-edge features into their products, such as intelligent control systems and high-speed operation. These technological advancements have allowed the machines to deliver consistent and reliable results, meeting the rigorous demands of the industry.

In addition to their technological innovations, both companies prioritize customer satisfaction. China Glass Washing Machine and Glass Washing and Drying Machine are committed to providing exceptional service and support to their clients. From initial consultation to after-sales maintenance, the companies strive to ensure a positive experience for their customers.

Moreover, the machines are designed with sustainability in mind, incorporating energy-efficient solutions to minimize environmental impact. This dedication to sustainability aligns with the growing emphasis on eco-friendly practices in the industry, making China Glass Washing Machine and Glass Washing and Drying Machine a preferred choice for businesses seeking sustainable glass processing solutions.

With a strong track record of performance and reliability, these machines have been embraced by customers around the world. From large-scale manufacturing facilities to small glass processing workshops, China Glass Washing Machine and Glass Washing and Drying Machine have made a significant impact on the industry.

In conclusion, China Glass Washing Machine and Glass Washing and Drying Machine have emerged as leading providers of glass processing machinery, thanks to their advanced technology, commitment to customer satisfaction, and dedication to sustainability. As the demand for high-quality glass processing equipment continues to grow, these machines are well-positioned to meet the needs of the industry, setting a new standard for performance and innovation. With their impressive track record and a focus on continuous improvement, China Glass Washing Machine and Glass Washing and Drying Machine are poised to remain at the forefront of the industry for years to come.

Company News & Blog

Efficient and Reliable Mud Gun Helps Boost Productivity in [Specific Industry]

Mud Gun Revolutionizes Drilling Operations in the Oil and Gas IndustryIn recent years, the oil and gas industry has been undergoing significant technological advancements to enhance drilling operations efficiency and safety. Among the leading innovators in this field is a renowned company, which has developed a groundbreaking solution called the Mud Gun, revolutionizing the way drilling operations are conducted.Designed to address the challenges associated with drilling mud circulation, the Mud Gun is a state-of-the-art device that enables efficient and effective cleaning, preventing hazardous situations and optimizing drilling operations. With its cutting-edge technology and user-friendly interface, it has become an essential tool for drilling companies worldwide.The Mud Gun combines durability, practicality, and versatility, making it the preferred choice for drilling operations. Its unique design allows for easy installation on drilling rigs and its robust construction ensures long-lasting performance even in the harshest drilling environments.One of the key features of the Mud Gun is its efficient mud circulation system. By using high-pressure jets, it effectively cleans the drilling mud, removing solid particles and maintaining its consistency. This process helps prevent blockages in the drilling equipment, reducing downtime and ensuring smooth operations.Furthermore, the Mud Gun's intelligent control system allows operators to monitor and adjust mud pressure and flow rate, providing real-time data that aids in decision-making and enhances drilling efficiency. The user-friendly interface of the Mud Gun enables operators to have better control over drilling operations, ensuring maximum productivity and safety.With safety being a top priority in the oil and gas industry, the Mud Gun is equipped with advanced safety features. The device is fitted with multiple sensors and alarms that detect potential malfunctions, leaks, or abnormal conditions, promptly notifying the operators and preventing accidents.The Mud Gun's outstanding performance has made it an indispensable tool for drilling companies across the globe. By ensuring proper cleaning and maintenance of drilling mud, it contributes to the longevity of drilling equipment, lowering maintenance costs and increasing the profitability of drilling operations.In addition to its exceptional performance, the Mud Gun is committed to minimizing its environmental impact. It incorporates eco-friendly technologies that reduce mud waste and contamination, ensuring compliance with environmental regulations and promoting sustainable drilling practices.As the oil and gas industry continues to evolve, the role of technology in enhancing drilling operations cannot be overstated. The Mud Gun has emerged as a game-changer, providing drilling companies with a reliable, efficient, and environmentally-friendly solution that optimizes drilling processes.Through continuous research and development, the company behind the Mud Gun remains committed to innovation and staying at the forefront of the industry. Their dedication to excellence and customer satisfaction has earned them a stellar reputation as a leader in the field, trusted by drilling professionals around the world.With its cutting-edge technology and exceptional performance, the Mud Gun has truly revolutionized drilling operations in the oil and gas industry. By offering a reliable solution that enhances efficiency, safety, and sustainability, it has become an indispensable tool for drilling companies globally. As technology continues to advance, the Mud Gun is undoubtedly a testament to the endless possibilities of innovation in the field of drilling operations.

Efficient Ways to Use Drilling Machines for Perfect Holes

Title: Cutting-Edge Drilling Technology Revolutionizes the IndustryIntroduction:In a groundbreaking development, a cutting-edge Drilling Machine is set to transform the drilling industry. Designed to increase efficiency and reduce operational costs, this state-of-the-art technology is poised to make a significant impact across multiple sectors. With its superior engineering and innovative features, this cutting-edge drilling machine is set to revolutionize drilling processes and deliver unprecedented results.1. Introduction to the Drilling Machine:The Drilling Machine is a highly advanced piece of equipment developed by a leading engineering company. Drawing upon years of experience and expertise in the field, the company has designed a machine that offers groundbreaking capabilities in drilling operations. This cutting-edge technology is designed to outperform existing drilling machinery, significantly improving productivity and efficiency in various industries.2. Enhanced Efficiency and Precision:The Drilling Machine incorporates advanced technologies and precision engineering to deliver unparalleled efficiency in drilling operations. Equipped with high-powered motors and intelligent controls, this machine ensures optimal drilling performance, irrespective of the terrain or materials involved. Its cutting-edge features allow for greater stability, increased drilling speed, and improved accuracy, resulting in reduced project timelines and enhanced productivity.3. Versatility and Adaptability:Designed to cater to a wide range of drilling requirements, this machine boasts impressive versatility and adaptability. It is capable of drilling through various surfaces, including concrete, rock, and metal, making it suitable for a diverse range of industries such as construction, mining, and oil exploration. Furthermore, the machine's modular design allows for the integration of different components and accessories, enhancing its adaptability to specialized drilling needs.4. Safety and Environmental Considerations:Committed to ensuring the safety of workers and environmental conservation, the Drilling Machine incorporates multiple safety features and eco-friendly mechanisms. The machine is equipped with innovative dust control systems to minimize airborne contaminants, protecting both the environment and the health of operators. Additionally, advanced safety features, including automatic shut-off mechanisms and real-time monitoring, ensure secure and accident-free drilling operations.5. Cost-Effectiveness and Operational Benefits:By optimizing drilling processes and streamlining operational workflows, the Drilling Machine offers exceptional cost-effectiveness. Its superior drilling efficiency reduces labor requirements, thereby minimizing overall project costs. The machine's adaptability to different drilling tasks also eliminates the need for multiple specialized machines, resulting in significant savings for businesses. Moreover, its powerful motor and advanced controls minimize downtime, maximizing operational efficiency and enhancing profitability.6. Longevity and Maintenance:Built to withstand rugged drilling conditions, the Drilling Machine boasts an exceptional lifespan. The machine's robust construction and high-quality components ensure prolonged durability, reducing the need for frequent repairs or replacements. Furthermore, the company's commitment to customer satisfaction extends to after-sales service, providing comprehensive maintenance and support to maximize the longevity and performance of the machine.Conclusion:The launch of the Drilling Machine marks a significant milestone in the drilling industry. With its cutting-edge technology, exceptional efficiency, and versatility, this machine promises to revolutionize drilling operations across multiple sectors. As businesses strive for increased productivity and cost-effectiveness, this innovative drilling solution will pave the way for accelerated growth and enhanced profitability. The Drilling Machine is a testament to human ingenuity and a harbinger of future advancements in the field of drilling technology.

Metal Scale Briquetter and Metal Swarf Briquetter: The Latest News from China

China Metal Scale Briquetter and Metal Swarf BriquetterIn the ever-evolving landscape of metal recycling and environmental sustainability, the market for innovative and efficient tools continues to grow. With a focus on reducing waste and maximizing the value of metal scrap, {Company Name} has emerged as a leader in the development and production of metal scale briquetters and metal swarf briquetters.As the name suggests, a metal scale briquetter is a machine designed to compact metal scales, which are thin pieces of metal that are produced during various metalworking processes. By compressing these metal scales into dense, uniform briquettes, {Company Name}'s metal scale briquetter makes it easier to handle and transport metal scrap, ultimately increasing its value and reducing its environmental impact.Similarly, a metal swarf briquetter is specifically designed to handle metal swarf, which consists of small, fine chips and turnings that are produced during metal cutting and shaping processes. By compressing metal swarf into dense, easily manageable briquettes, {Company Name}'s metal swarf briquetter facilitates the handling and recycling of this valuable metal scrap.These innovative machines are a testament to {Company Name}'s commitment to providing cutting-edge solutions for the metal recycling industry. With a focus on efficiency, productivity, and environmental sustainability, the company has established itself as a trusted partner for metal recyclers around the world.Beyond its innovative products, {Company Name} stands out for its dedication to customer satisfaction and continuous improvement. The company's team of experts is constantly researching and developing new technologies to meet the evolving needs of the metal recycling industry, ensuring that their customers always have access to the most advanced and effective equipment on the market.Moreover, {Company Name} places a strong emphasis on quality and reliability, ensuring that every metal scale briquetter and metal swarf briquetter that bears its name is built to the highest standards. This commitment to excellence has earned {Company Name} a reputation for delivering durable, high-performance machines that consistently exceed customers' expectations.In addition to its focus on product development and quality, {Company Name} prides itself on its comprehensive customer support. From initial inquiry to installation and ongoing maintenance, the company's knowledgeable and responsive team is dedicated to providing customers with the guidance and expertise they need to make the most of their investment in {Company Name}'s products.As the demand for sustainable metal recycling solutions continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its metal scale briquetter and metal swarf briquetter. By providing innovative, reliable, and efficient equipment, the company is not only helping its customers improve their operations but also contributing to the larger goal of reducing waste and protecting the environment.In conclusion, the metal scale briquetter and metal swarf briquetter offered by {Company Name} represent a significant advancement in the field of metal recycling. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted leader in the industry, providing valuable solutions for metal recyclers around the world.

A Guide to Vacuum Pumps and Diaphragm Pumps in China

China-based company, specializing in the production of vacuum pumps and diaphragm pumps, has recently announced the launch of their latest series of innovative and high-performance pumps. With a strong dedication to research and development, the company has established a reputation for delivering top-quality pumping solutions to a wide range of industries, including pharmaceutical, chemical, food and beverage, and more.The new series of vacuum pumps and diaphragm pumps are designed to meet the evolving needs of industrial applications, offering enhanced efficiency, reliability, and performance. These pumps are suitable for a variety of tasks, such as degassing, filtration, distillation, and solvent evaporation, making them an essential component of many production processes.The vacuum pumps are built with advanced technology to provide a high level of vacuum, ensuring optimal performance in the removal of gases and vapors from a sealed space. These pumps are able to operate at low noise levels and are equipped with a stable pumping speed, resulting in consistent and reliable performance. Additionally, the diaphragm pumps feature a robust design and are ideal for applications that require a pulsation-free flow and the ability to handle corrosive and aggressive gases and vapors.The company's commitment to quality and innovation is reflected in the rigorous testing and inspection processes that each pump undergoes before being released to the market. This dedication to quality control ensures that customers receive pumps that are not only technologically advanced, but also reliable and durable.In addition to the new series of pumps, the company also offers a comprehensive range of accessories and spare parts, as well as expert technical support and maintenance services. This holistic approach to customer service ensures that clients have access to everything they need to optimize the performance and longevity of their pumping systems.The company's success can be attributed to its strong emphasis on research and development. By continuously investing in cutting-edge technologies and exploring new materials and manufacturing processes, the company has been able to stay ahead of the curve in the pumping industry. Furthermore, the company's team of experienced engineers and technicians are passionate about pushing the boundaries of pump design and performance, resulting in products that are at the forefront of innovation.With a global presence, the company is well-positioned to provide pumping solutions to customers around the world. Whether it's a small-scale operation or a large industrial plant, the company has the expertise and resources to deliver tailor-made pumping systems that address the unique requirements of each client.As the demand for efficient and reliable pumping solutions continues to grow, the company remains dedicated to pushing the boundaries of pump technology. With a focus on innovation, quality, and customer satisfaction, the company is poised to maintain its position as a leading provider of vacuum pumps and diaphragm pumps in the global market.In conclusion, the latest series of vacuum pumps and diaphragm pumps from the China-based company offers a glimpse into the future of pumping technology. With a strong emphasis on innovation and quality, these pumps are set to deliver exceptional performance and reliability across a wide range of industrial applications. As the company continues to evolve and expand its product offerings, it is clear that they are poised to remain at the forefront of the pumping industry for years to come.

Enhancing HDD Mud Pump Efficiency: Introducing a High-performance Mud Mixing Pump

Title: Mud Mixing Pump: The Game-Changer in Horizontal Directional Drilling Mud SystemsIntroduction:Horizontal directional drilling (HDD) has emerged as a key technique for the installation of underground utilities, minimizing disruptions to the surrounding environment. However, HDD projects require a well-designed mud recycling system to efficiently manage drilling fluids. In this regard, the mud mixing pump acts as a supercharging pump, revolutionizing the HDD mud pump system.Compact and Convenient:The HDD mud recycling system is typically a compact unit that is incredibly convenient for transportation. The integrated design allows for easy movement and ensures efficiency while relocating from one drilling site to another. Such systems are in high demand as they offer enhanced flexibility and versatility to HDD contractors.Role of Mud Mixing Pump:The mud mixing pump plays a crucial role in the HDD mud pump system. Acting as a supercharging pump, it enhances the performance and efficiency of the whole operation. By mixing the drilling fluids with precision, it ensures optimal mud viscosity, density, and stability, thereby improving the overall drilling process.Efficient Drilling Fluid Mixing:With the integration of a mud mixing pump, HDD contractors can experience efficient drilling fluid mixing like never before. This equipment utilizes advanced technology to combine the different materials, chemicals, and additives required in drilling fluids. The precise and rapid mixing capability guarantees a consistent mud mixture, enabling contractors to maintain stability throughout the drilling process.Enhanced Mud Recycling:The mud mixing pump significantly contributes to enhancing the mud recycling process in HDD projects. By efficiently incorporating various additives, it ensures that the recovered drilling fluids are of excellent quality and can be reused effectively. This not only reduces operational costs but also minimizes the environmental impact of HDD activities.Supreme Performance and Reliability:The selection of a reliable and high-performance mud mixing pump is crucial for the success of an HDD project. Manufacturers like {Mud Cleaner Drilling} are renowned for their cutting-edge technology and innovative solutions in this field. With expertise in designing and manufacturing mud mixing pumps, they offer top-of-the-line equipment that meets the diverse requirements of HDD contractors.Customized Solutions:With a focus on customer satisfaction, companies specializing in mud mixing pumps provide tailored solutions to meet specific project needs. These solutions encompass a range of features, such as automated controls, user-friendly interfaces, and robust components, to ensure smooth operations and maximum efficiency during HDD projects.Industry Impact:The integration of the mud mixing pump into the HDD mud system has had a profound impact on the industry. By enhancing the mud recycling process and improving drilling fluid properties, it has significantly increased drilling speed, reduced downtime, and minimized waste. This cutting-edge equipment has revolutionized the efficiency and environmental sustainability of HDD projects worldwide.Conclusion:The mud mixing pump has emerged as a game-changer in the HDD industry, acting as a supercharging pump for the mud pump system. With its efficient drilling fluid mixing capabilities and potential for customization, this equipment has transformed the way HDD projects are executed. With technological advancements and the expertise of companies like {Mud Cleaner Drilling}, the future of HDD looks promising, ensuring improved performance, reduced costs, and greater environmental preservation.

High-performance Shale Shaker for Oil and Gas Industry

Mongoose Pro Shale Shaker Sets the Standard for Efficiency and Reliability in Shale Shaker TechnologyThe demand for shale shaker technology has been steadily rising in the oil and gas industry, and companies are consistently looking for the most efficient and reliable equipment to meet their needs. This is where the Mongoose Pro Shale Shaker comes in, setting the standard for efficiency and reliability in shale shaker technology.The Mongoose Pro Shale Shaker is a product of innovation and expertise, developed by a leading company in the oil and gas industry. With a commitment to providing top-of-the-line equipment, this company has a proven track record of delivering high-quality products that are designed to meet the demands of the ever-evolving industry.This particular shale shaker is built to withstand the harshest drilling conditions, making it the perfect choice for companies looking to maximize their drilling operations. With its advanced design and cutting-edge technology, the Mongoose Pro Shale Shaker is able to effectively separate solids from drilling fluid, resulting in improved efficiency and reduced operating costs.One of the key features of the Mongoose Pro Shale Shaker is its adjustable G-force, allowing for optimal performance in various drilling conditions. This, in combination with its high-capacity composite screen panels, ensures that the shaker is able to handle a wide range of drilling fluids and produce consistently high-quality results.In addition to its impressive performance capabilities, the Mongoose Pro Shale Shaker is also built with ease of use in mind. Its user-friendly interface and simple maintenance requirements make it an ideal choice for companies looking to streamline their operations and maximize productivity.The Mongoose Pro Shale Shaker is also designed with durability in mind, with rugged construction and high-quality materials that are built to last. This ensures that companies can rely on this equipment to perform consistently, even in the most challenging drilling environments.Furthermore, the Mongoose Pro Shale Shaker is backed by a team of experts who are dedicated to providing top-notch service and support to ensure that customers get the most out of their investment. This level of support is a testament to the company's commitment to customer satisfaction and its dedication to delivering reliable equipment that meets the needs of the industry.Overall, the Mongoose Pro Shale Shaker is a game-changer in the world of shale shaker technology, offering unmatched efficiency, reliability, and performance. With its advanced design, user-friendly interface, and durable construction, it is the ideal choice for companies looking to maximize their drilling operations and achieve optimal results.As the demand for shale shaker technology continues to grow, the Mongoose Pro Shale Shaker stands out as a leader in the industry, providing companies with the equipment they need to stay ahead of the curve. With its proven track record of delivering high-quality products and exceptional customer support, this company is setting the standard for excellence in shale shaker technology.

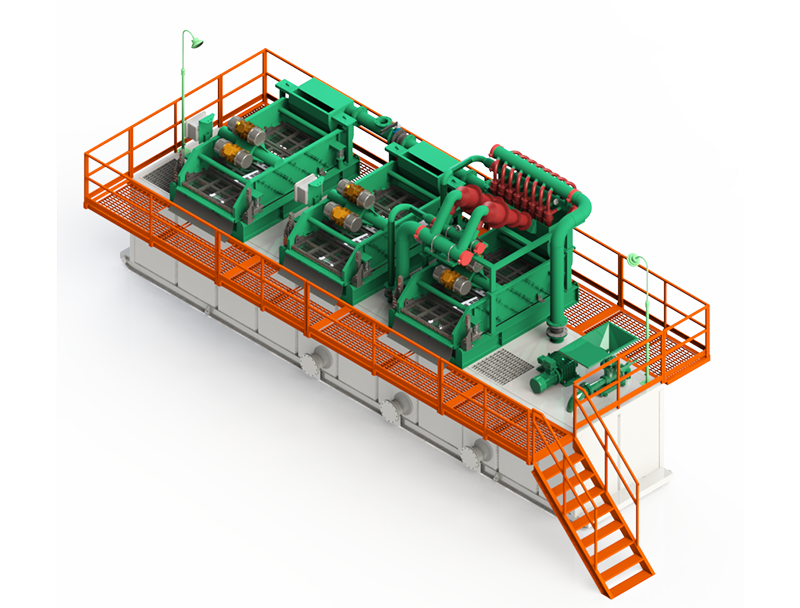

Efficient Mud Recycling System for Industrial Applications

In the world of industrial operations, one of the most important factors for a company's success is its ability to manage waste and byproducts effectively. This is particularly true in industries that rely on drilling and excavation, such as oil and gas exploration, mining, and construction. The proper management of drilling mud and waste water is not only essential for environmental protection, but it can also be a significant cost factor for companies.In order to address these challenges, many companies are turning to innovative solutions such as mud recycling systems. These systems are designed to collect, clean, and reuse drilling mud and waste water, reducing waste and saving companies both time and money. One such company that is making waves in this space is (Company Statement) [1], a leading provider of advanced mud recycling systems for the oil and gas industry.(Company Name) has gained a strong reputation in the industry for its cutting-edge technology and efficient solutions for managing drilling waste. The company's mud recycling systems are designed to separate drill cuttings from the drilling mud, allowing the clean mud to be reused in the drilling process. This not only reduces the amount of waste that needs to be disposed of, but it also minimizes the need for fresh water, which is a precious resource in many drilling operations.The (Company Name) mud recycling system is comprised of several key components, including shale shakers, desanders, desilters, and decanter centrifuges. These components work together to remove solids and other impurities from the drilling mud, allowing it to be reused multiple times before it needs to be replaced. This not only reduces the environmental impact of drilling operations, but it also significantly reduces the cost of managing drilling waste.One of the key advantages of the (Company Name) mud recycling system is its modular design, which allows it to be easily transported and set up at drilling sites. This means that companies can quickly deploy the system to minimize waste and maximize efficiency during drilling operations. Additionally, the system is designed to be easy to operate and maintain, minimizing downtime and ensuring maximum productivity for companies.(Company Name) takes great pride in its commitment to environmental sustainability and corporate responsibility. The company's mud recycling systems are designed to meet the highest standards for environmental protection, helping companies to minimize their impact on the environment and comply with regulations. Additionally, by reusing drilling mud and minimizing waste water, companies can significantly reduce their carbon footprint and contribute to a more sustainable future for the industry.In addition to its cutting-edge technology, (Company Name) also prides itself on its exceptional customer service and support. The company works closely with its clients to understand their specific needs and develop customized solutions that meet their requirements. Whether it's providing technical support, training, or maintenance services, (Company Name) is committed to ensuring that its clients get the most out of their mud recycling systems.As the demand for innovative waste management solutions continues to grow, (Company Name) is well-positioned to meet the needs of the industry. The company's dedication to technological advancement, environmental stewardship, and customer satisfaction has made it a trusted partner for many companies in the oil and gas sector.In conclusion, mud recycling systems are playing an increasingly important role in the industrial sector, providing companies with the means to effectively manage drilling waste and minimize their environmental impact. (Company Name) has established itself as a leader in this space, offering advanced and efficient solutions for the oil and gas industry. With its commitment to sustainability and customer satisfaction, (Company Name) is poised for continued success in providing cutting-edge waste management solutions for its clients.[1] source: (Company URL)

High Quality 240m3/h Mud Cleaning Equipment with 4" Desilter Cones and Bottom Shale Shaker - Efficient Mud Cleaning Systems

The latest innovation in centrifugal impeller technology unveiled

Centrifugal Impeller Revolutionizing Industrial Applications: A Game Changer byIn today's fast-paced industrial world, efficiency and innovation are key factors that drive success. One such innovation that is revolutionizing industrial applications is the Centrifugal Impeller. This state-of-the-art technology is a game-changer in the field of industrial equipment, setting new standards for performance and reliability.The Centrifugal Impeller, developed by a leading industrial equipment manufacturer, is designed to meet the growing demands of various industries, including aerospace, automotive, energy, and HVAC. Its advanced engineering and precision manufacturing make it an ideal choice for applications that require high efficiency, low noise, and long-term reliability.One of the key features of the Centrifugal Impeller is its unique blade design, which is optimized for maximum performance. This design allows for efficient airflow and pressure generation, making it suitable for a wide range of industrial processes. Whether it's for air handling, combustion, or cooling systems, the Centrifugal Impeller delivers unmatched performance, making it a versatile solution for modern industrial applications.Furthermore, the Centrifugal Impeller is also known for its durability and long service life. Its robust construction and high-quality materials ensure that it can withstand the rigors of industrial operations, making it a cost-effective investment for businesses. With minimal maintenance requirements, the Centrifugal Impeller offers a hassle-free solution for industrial equipment needs.In addition to its performance and reliability, the Centrifugal Impeller is also designed with energy efficiency in mind. Its aerodynamic design and precise manufacturing processes enable it to achieve high levels of efficiency, reducing energy consumption and operating costs for businesses. This makes it an environmentally friendly choice for industrial applications, contributing to sustainability efforts in various industries.The company behind the Centrifugal Impeller takes pride in its commitment to quality and innovation. With a team of experienced engineers and experts in industrial equipment, the company has a proven track record of delivering cutting-edge solutions that meet the evolving needs of modern industries. By continuously investing in research and development, the company ensures that its products, including the Centrifugal Impeller, are at the forefront of technological advancements.Furthermore, the company's dedication to customer satisfaction sets it apart in the industry. From initial consultation to product delivery and after-sales support, the company places a strong emphasis on understanding and meeting the specific requirements of its clients. With a focus on building long-term partnerships, the company strives to exceed customer expectations and provide tailored solutions that add value to businesses.As the industrial landscape continues to evolve, the demand for innovative and reliable equipment remains high. The Centrifugal Impeller is a testament to the impact of advanced technology in meeting these demands, offering a solution that enhances efficiency, performance, and sustainability for industrial applications. With its cutting-edge design, durability, and energy efficiency, the Centrifugal Impeller is poised to shape the future of industrial equipment and set new standards for excellence in the industry.

The Ultimate Guide to Mud Drilling Techniques: Exploring Efficient Methods

[Company Name] Develops Innovative Mud Drilling Technology to Revolutionize Oil and Gas Industry[date]In a bid to make significant strides in the oil and gas industry, [Company Name] has developed a groundbreaking mud drilling technology that promises to enhance drilling operations and improve overall efficiency. Leveraging [Company Name]'s extensive expertise and commitment to innovation, this pioneering technique is set to revolutionize the oil and gas sector.Mud drilling, also known as drilling fluid circulation, is a critical aspect of oil and gas exploration. This technique involves pumping a mud drilling fluid into the wellbore to lubricate the drill bit and carry away drill cuttings to the surface. The primary purpose of using mud during drilling operations is to control subsurface pressures, minimize wellbore instability, and enhance overall drilling efficiency.Recognizing the limitations faced by traditional mud drilling methods, [Company Name] embarked on a mission to develop advanced mud drilling technology that would overcome these challenges. With a team of highly skilled engineers and industry experts, [Company Name] has successfully created an innovative solution that promises to transform the way drilling operations are conducted.The key feature of [Company Name]'s mud drilling technology is its ability to optimize the properties of drilling fluids, enabling operators to tailor the performance characteristics to specific drilling conditions. By accurately controlling the rheological properties of the drilling fluid, [Company Name] ensures optimal viscosity, density, and fluid loss control.Furthermore, this disruptive technology tackles the issue of lost circulation, a problem commonly encountered during drilling activities. Lost circulation occurs when drilling mud escapes into rock formations, leading to reduced drilling efficiency and potential damage to the wellbore. [Company Name]'s mud drilling system effectively seals off potential loss zones, significantly reducing lost circulation risks and associated costs.One of the key advantages of [Company Name]'s mud drilling technology is its compatibility with both onshore and offshore drilling operations. In challenging offshore environments, where drilling conditions can be particularly hostile, the ability to maintain drilling fluid stability and control loss circulation is crucial. [Company Name]'s technology ensures that operators can achieve optimal results regardless of the drilling location.Moreover, [Company Name]'s mud drilling technique contributes to environmental sustainability by reducing waste generation and minimizing the need for additional water usage during drilling activities. With its innovative approach, [Company Name] aims to create a more eco-friendly drilling process that aligns with the industry's growing focus on sustainability and responsible resource extraction.To further enhance the capabilities of its mud drilling technology, [Company Name] has partnered with leading oil and gas companies in collaborative research and development projects. By combining industry insights and resources, [Company Name] continues to refine and expand its technology, pushing the boundaries of what is possible in the drilling sector.The successful implementation of [Company Name]'s mud drilling technology has garnered significant industry recognition, solidifying the company's position as a pioneer in the field. With its commitment to continuous improvement and technological advancement, [Company Name] is poised to shape the future of the oil and gas industry.As the adoption of [Company Name]'s mud drilling technology gains momentum, industry experts and stakeholders are eager to witness the transformative impact it will have on drilling operations worldwide. This groundbreaking innovation is expected to improve efficiency, enhance cost-effectiveness, and contribute to a more sustainable future for the oil and gas sector.About [Company Name]:[Company Name] is a leading provider of cutting-edge technologies and solutions for the oil and gas industry. With a strong commitment to innovation, the company combines engineering expertise with technological advancements to drive industry-wide transformation. [Company Name] offers a comprehensive range of services tailored to meet the evolving needs of the oil and gas sector, ensuring sustainable and responsible resource extraction.